ALTERNATOR

SERVICE

DESCRIPTION

The stator is

connected

to

a three-phase,

full-wave

bridge

rectifier package

which

contains

six

diodes.

The bridge

converts the

AC

generated

in

the

stator

to

a

DC

output

for

battery charging

and

accessories,

Power

to the regulator

and

the

field

of

the

integral regulator

alternator

is

provided

by

the

field

diode

(or

diode trio)

package contained

in

the

alternator.

These alternators produce a rated output of

50

or

51

amps.

rated output

is

achieved

at

approximately 6000 alternator

!pm at

an

ambient temperature of 75'F (23.8'C). The

alternators are

designed

to

operate

in

an

ambient temperature

range of

-40'

to

212'F (-40'

to

lOO'C).

INSPECnDN

When

rebuilding

the

engine,

the

alternator

should

be

cleaned

and

inspected. The housing

can

be

wiped

off

with

a solvent

and

the alternator

temninal

studs should

be

cleaned

with

a

wire

brush.

Make

certain

the

studs

are

tight

and

clean

the

wiring connections that connect

to

the

wiring

harness.

Thm

the rotor

pulley

by

hand.

It

should tum

smoothly.

DISASSEMBLE

ALTERNATOR

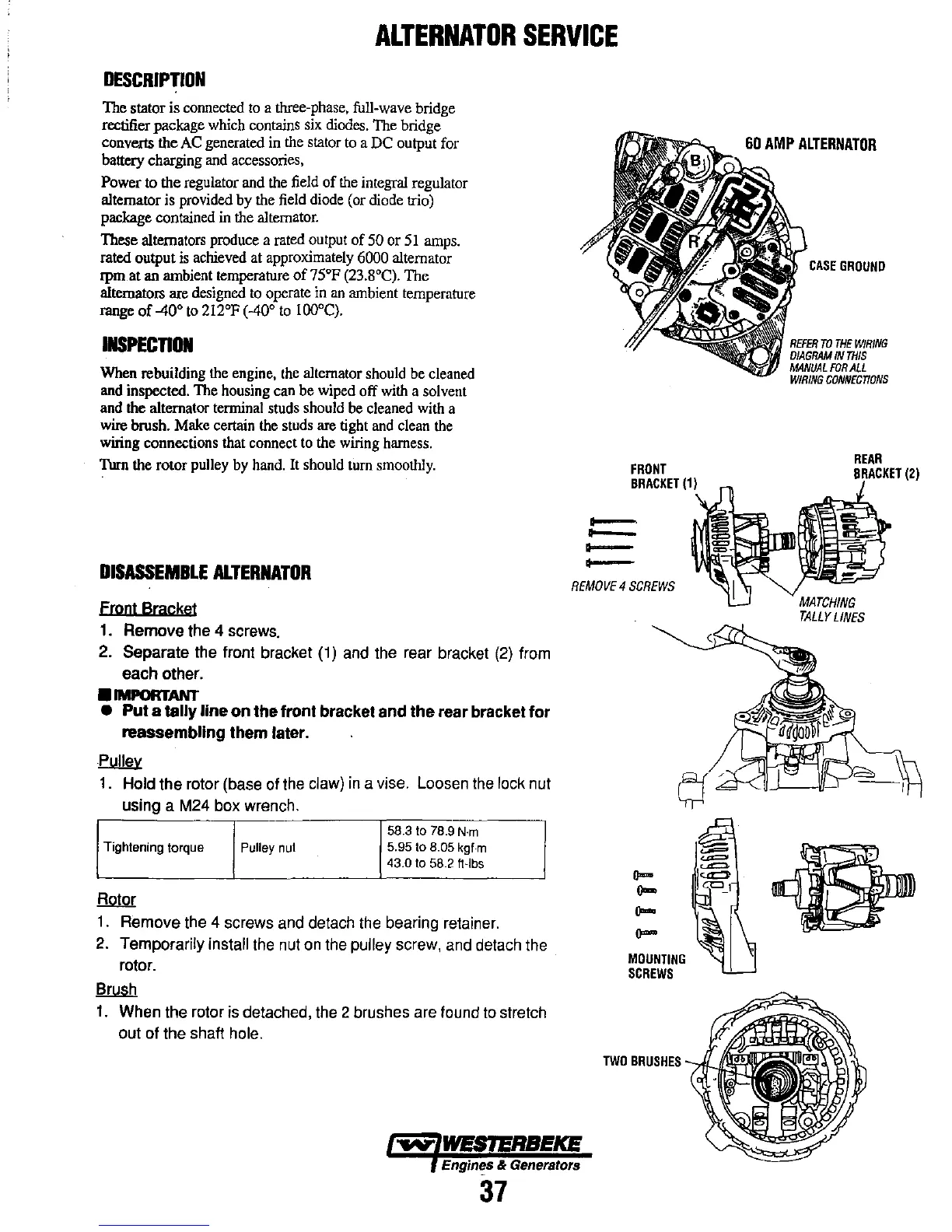

Front Bracket

1. Remove the 4 screws.

2.

Separate the fron! bracket (1) and the rear bracket

(2)

from

each other .

•

IMPORTANT

•

Put

a tally

line

on

the

front

bracket

and

the

rear bracket

for

reassembling

them

later.

Pulley

1.

Hold the rotor (base of the claw)

in

a vise. Loosen the lock nut

using a M24 box wrench.

58.3

to

78.9

N·m

Tightening torque Pulley nul 5.95

to

8.05 kgf·m

43.0

to

58.2 ft·lbs

Rotor

1.

Remove the 4 screws and detach the bearing retainer.

2. Temporarily install the nut

on

the pulley screw, and detach the

rotor.

Brush

1.

When the rotor is detached, the 2 brushes are found

to

stretch

out of the shaft hole.

FRONT

BRACKET

(1)

--

-

--

-

REMOVE

4

SCREWS

0-

0-

0-

0-

MOUNTING

SCREWS

TWO

BRUSHES

Engin'!.s & Generators

37

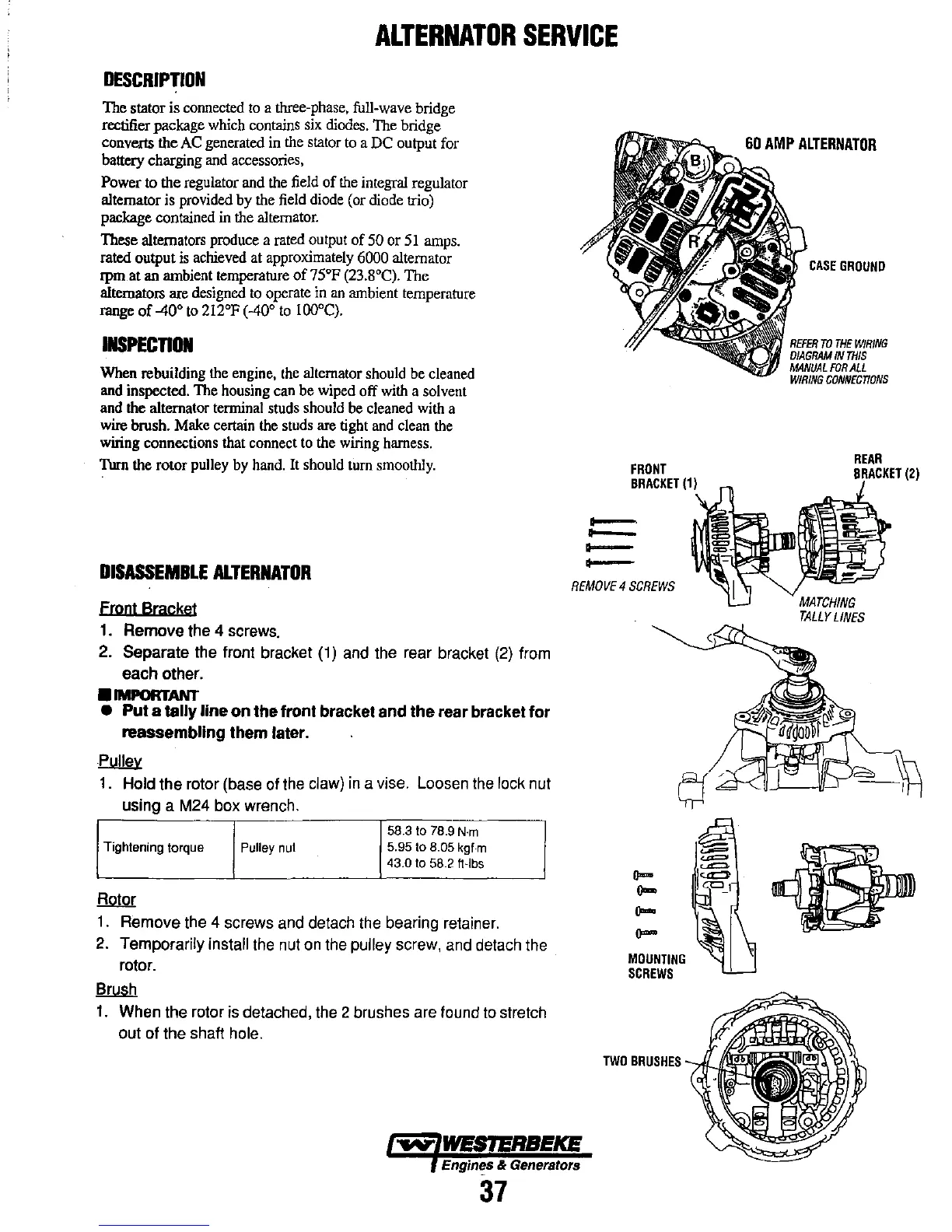

60

AMP

ALTERNATOR

CASE

GROUND

REFER

TO

THE

WIRING

DIAGRAM

IN

THIS

MANUAL

FOR

ALL

WIRING

CONNECnONS

REAR

BRACKET

(2)

Loading...

Loading...