DISASSEMBLY

I

ASSEMBLY

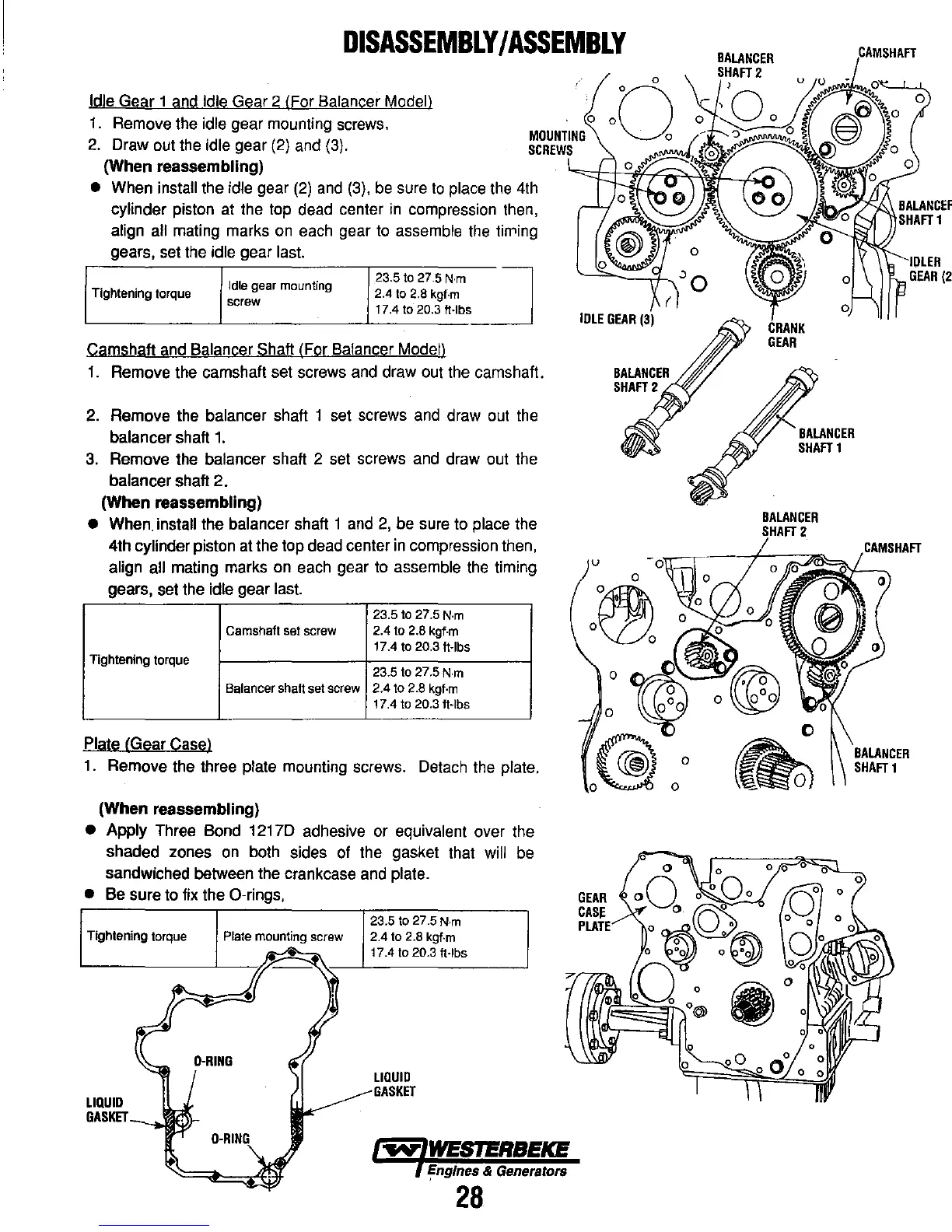

Idle Gear 1 and Idle Gear 2 (For Balancer Modell

1.

Remove the idle gear mounting screws.

2. Draw out the idle gear (2) and (3).

(When

reassembling)

o

MOUNTING

SCREWS

• When install the idle gear

(2)

and

(3),

be

sure

to

place the 4th

cylinder piston at the top dead center

in

compression then,

align all mating marks

on

each gear

to

assemble the

tifTling

gears, set the idle gear last.

Tightening

torque

Idle

gear

mounting

screw

23.5 to 27.5

N·m

~

2.4 to 2.8 kgf·m

17.4 to 20.3 ft·lbs

Camshaft and Balancer Shaft (For Balancer Model)

1.

Remove the camshaft set screws and draw out the camshaft.

2.

Remove the balancer shaft 1 set screws and draw out the

balancer shaft

1.

3.

Remove the balancer shaft 2 set screws and draw out the

balancer shaft

2.

(When

reassembling)

• When. install the balancer shaft 1 and

2,

be sure to place the

4th

cylinder piston at the top dead center

in

compression then,

align all mating marks on each gear to assemble the timing

gears, set the

idle gear last.

23.5 to 27.5

N·m

Camshaft

set

screw

2.4 to 2.8 kgf·m

17.4 to 20.3 ft·lbs

Tightening

torque

23.5 to 27.5

N·m

Balancer

shaft

set

screw

2.4 to 2.8 kgf·m

17.4 to 20.3 It·lbs

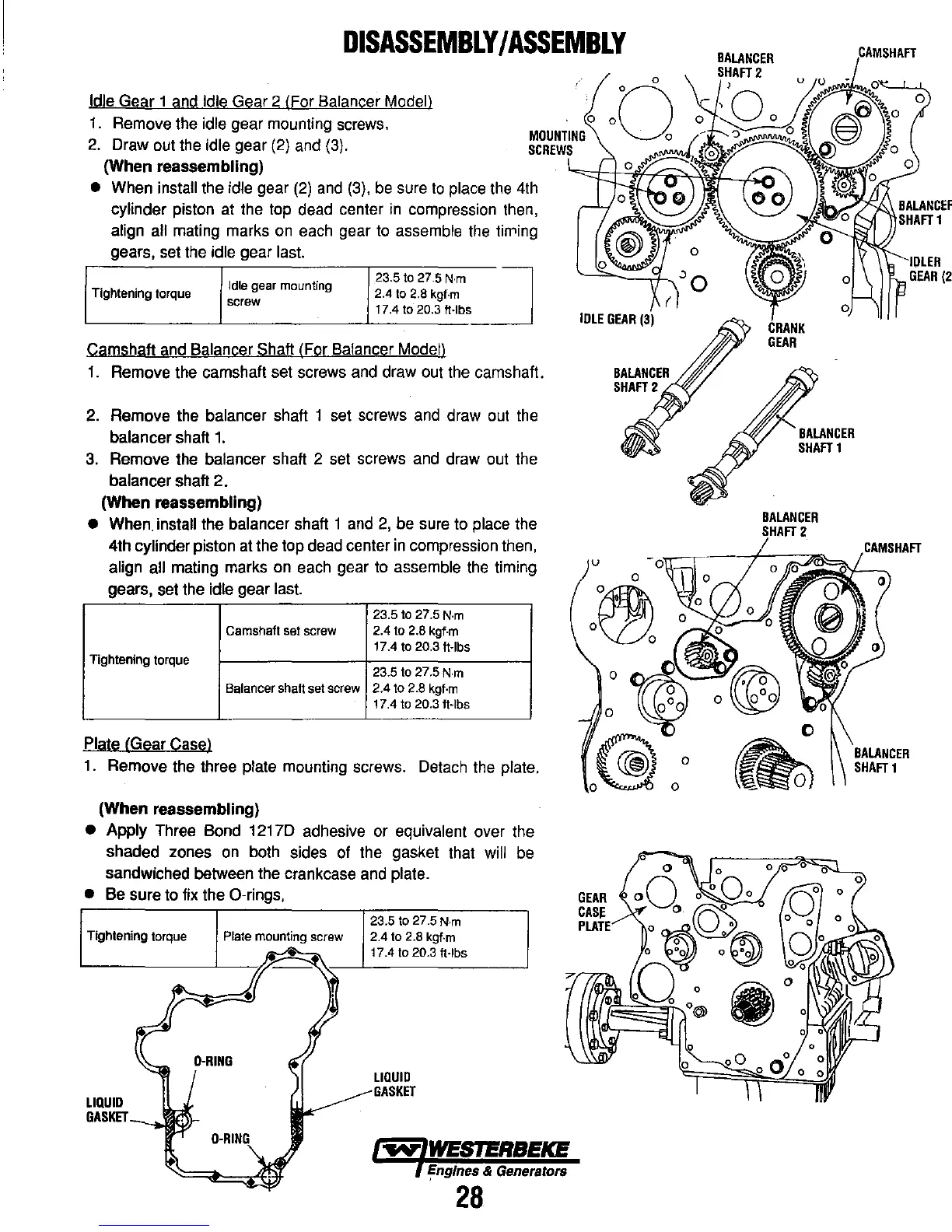

Plate (Gear Case)

1.

Remove the three plate mounting screws. Detach the plate.

(When

reassembling)

• Apply Three Bond 12170 adhesive or equivalent over the

shaded zones

on

both sides of the gasket that will be

sandwiched between the crankcase and

plate.

•

Be sure to fix the O-rings.

23.5 to 27.5

N·m

Tightening

torque

Plate

mounting

screw

2.4

to

2.8

kgf·m

LIQUID

GASKET

17.4 to 20.3 ft·lbs

LIQUID

GASKET

I!ngfnes & Generators

28

v

o

o

GEAR

CASE

PLATE

o

o

CRANK

GEAR

BALANCER

SHAFT

1

BALANCER

2

CAMSHAFT

Loading...

Loading...