SERVICING

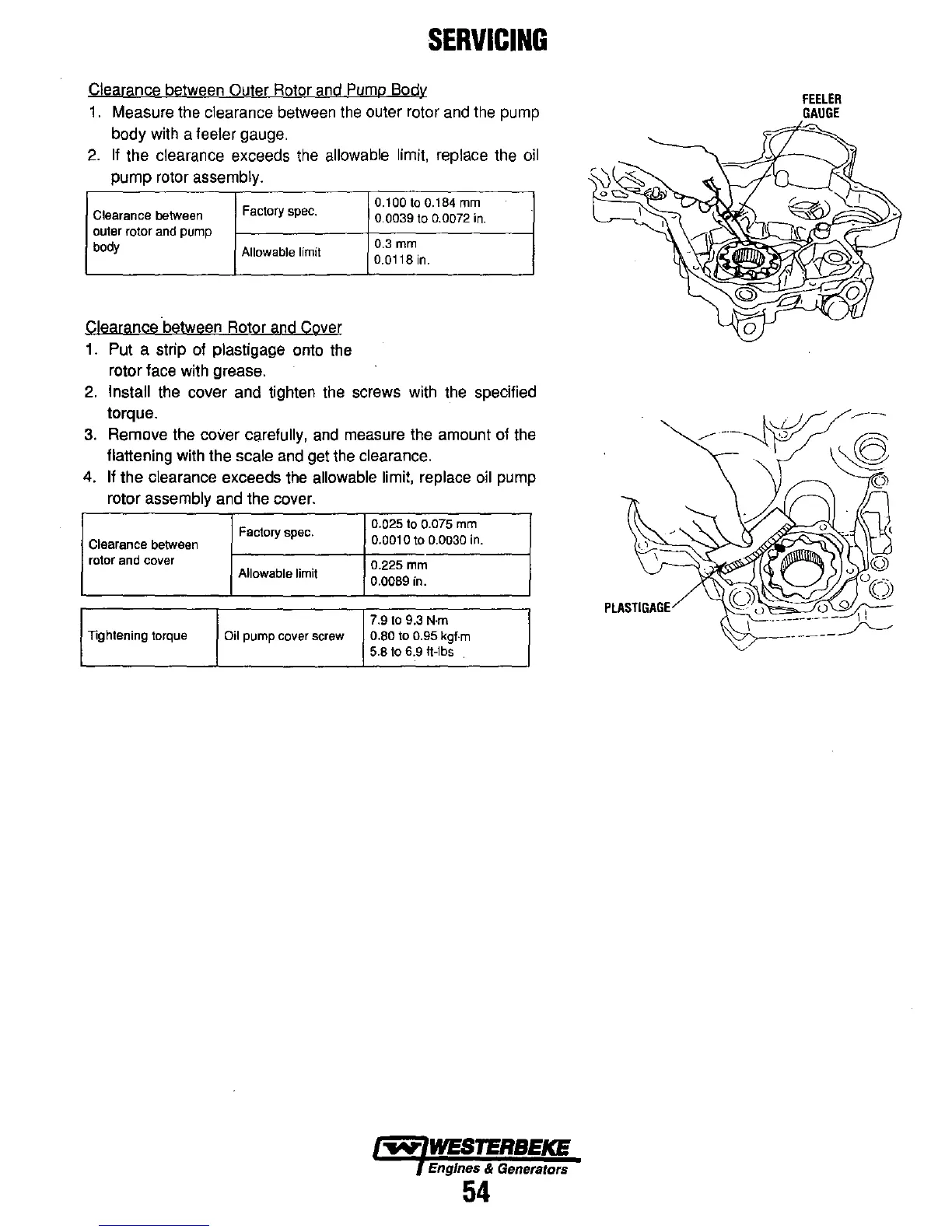

Clearance between Outer Rotor and

Pump

Body

1.

Measure the clearance between

the

outer rotor and the pump

body with a feeler gauge.

2.

If

the clearance exceeds the allowable limit, replace the oil

pump rotor assembly.

Clearance

between

Factory

spec.

outer

rotor

and

pump

body

Allowable

limit

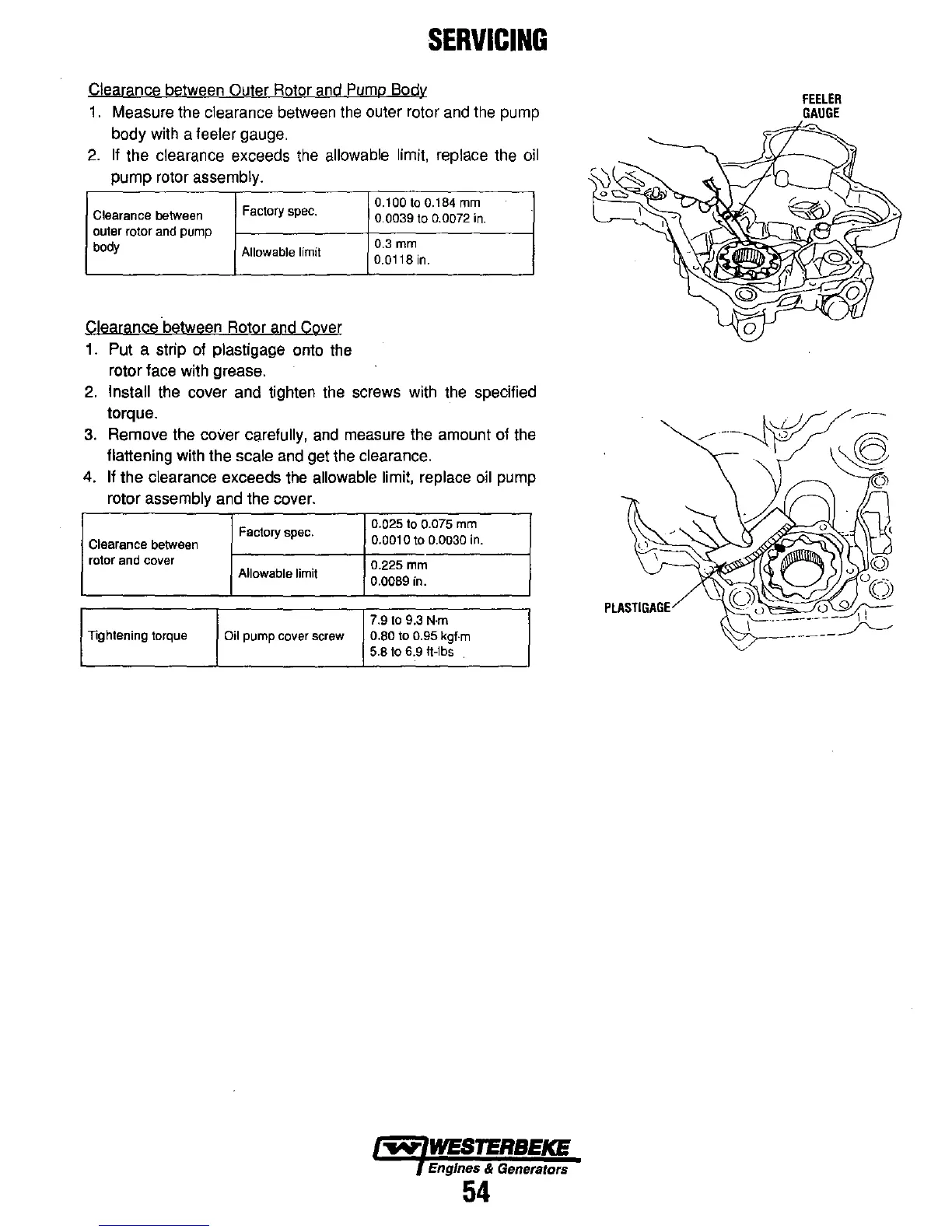

Clearance between Rotor and Cover

1.

Put a strip

of

plastigage onto the

rotor face with grease.

0.100

to

0.184

mm

0.0039

to

0.0072

in.

0.3

mm

0.0118

in.

2.

Install the cover and tighten the screws with the specified

torque.

3.

Remove the cover carefully,

and

measure the amount of the

flattening with the scale and get the clearance.

4.

If the clearance exceeds the allowable limit, replace oil pump

rotor assembly and the cover.

Factory

spec.

0.02510 0.075

mm

Clearance

between

0.0010

to

0.0030

in.

rotor

and

cover

0.225 mm

Allowable

limit

0.0089 in.

7.9

to

9.3

N·m

Tightening

torque

Oil

pump

cover

screw

0.80

to

0.95

kgf·m

5.8

to

6.9 tt-Ibs .

..,y"

WESTERBEKE

Engines

&

Generators

54

PLASTIGAGE

FEELER

GAUGE

Loading...

Loading...