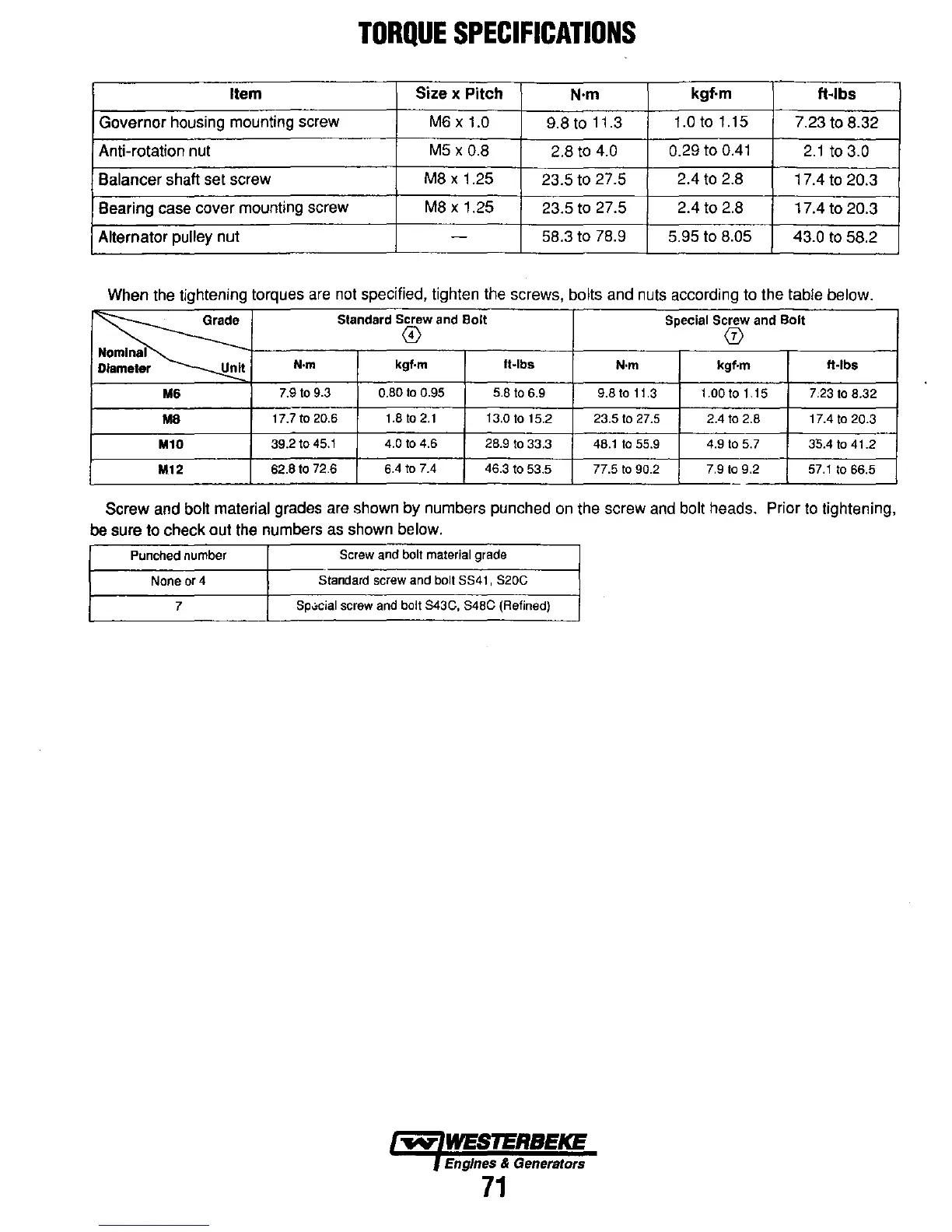

TORQUE

SPECIFICATIONS

Item

Size

x Pitch

N·m

kgf·m

ft-lbs

Governor housing mounting screw M6 x 1.0

9.8 to 11.3

1.0t01.15

7.23 to 8.32

Anti-rotation nut

M5 x 0.8

2.8 to 4.0

0.29 to

0.41

2.1

to

3.0

Balancer shaft set screw

M8 x 1.25

23.5 to 27.5

2.4

to

2.8

17.4

to

20.3

Bearing case cover mounting screw

M8 x 1.25

23.5

to

27.5

2.4 to 2.8

17.4 to 20.3

Alternator pulley nut -

58.3 to 78.9

5.95 to 8.05 43.0

to

58.2

When the tightening torques

are

not specified, tighten the screws, bolts and nuts according to the table below.

!~e

Standard Screw

and

Bolt

Special Screw and Bolt

@

(j)

Nominal

Diameter

Unit

N·m

kgf·m

It·lbs

N·m kgf·m

It·lbs

M6

7.9

to

9.3 0.80

to

0.95 5.8

to

6.9

9.8

to

t t.3

t.OO

to

1.15 7,23

to

8.32

M8

t7.7

to

20.6

t.8

to

2.t

13.0

to

15.2 23.5

to

27.5

2.4

to

2.8 17.4

to

20.3

M10

39.2 to

45.1

4.0

to

4.6 28.9

to

33.3

48.11055.9 4.9

to

5.7 35.4

to

41.2

M12

62.8 to 72.6

6.4

to

7.4 46.3 to 53.5

77.5

to

90.2 7.9

to

9.2

57.1

to

66.5

Screw and bolt material grades are shown by numbers punched

on

the screw and bolt heads. Prior

to

tightening,

be sure

to

check out the numbers as shown below.

Punched

number

Screw

and

bolt

material

grade

None

or

4

Standard

screw

and

bolt

8841 , S20C

7

Sp.;cial screw and bolt S43C, S48C (Refined)

Engines

& Generators

71

Loading...

Loading...