en Operation

64 WILO SE 2019-07

6.5.17 Connection ModBus RTU

NOTICE

Do not apply external voltage!

An external voltage which is applied destroys the component.

J4

J3

J2

J4

J2

J3

Control EC/ECe-B2 Control EC/ECe-B3

Fig.22: Jumper position

See Overview of components: Wilo-Control EC-Booster [}56] for position numbers

9 ModBus: RS485 interface

10 ModBus: Jumper for termination/polarisation

The ModBus protocol is available for connection to a building management system. In-

sert the connection cable laid by the customer through the threaded cable glands and

secure. Connect the wires to the terminal strip according to the connection diagram.

Observe the following points:

▪Interface: RS485

▪Field bus protocol settings: Menu 2.01 to 2.05.

▪The switchgear is terminated at the factory. Remove termination: Remove jumper “J2”.

▪If the ModBus requires a polarisation, plug in jumpers “J3” and “J4”.

7 Operation

DANGER

Risk of fatal injury due to electrical current!

Only operate the switchgear when closed. There is a risk of fatal injury from open

switchgear! Electrical work on the internal components must be carried out by a

qualified electrician.

7.1 How it works

Wilo-Control EC-Booster

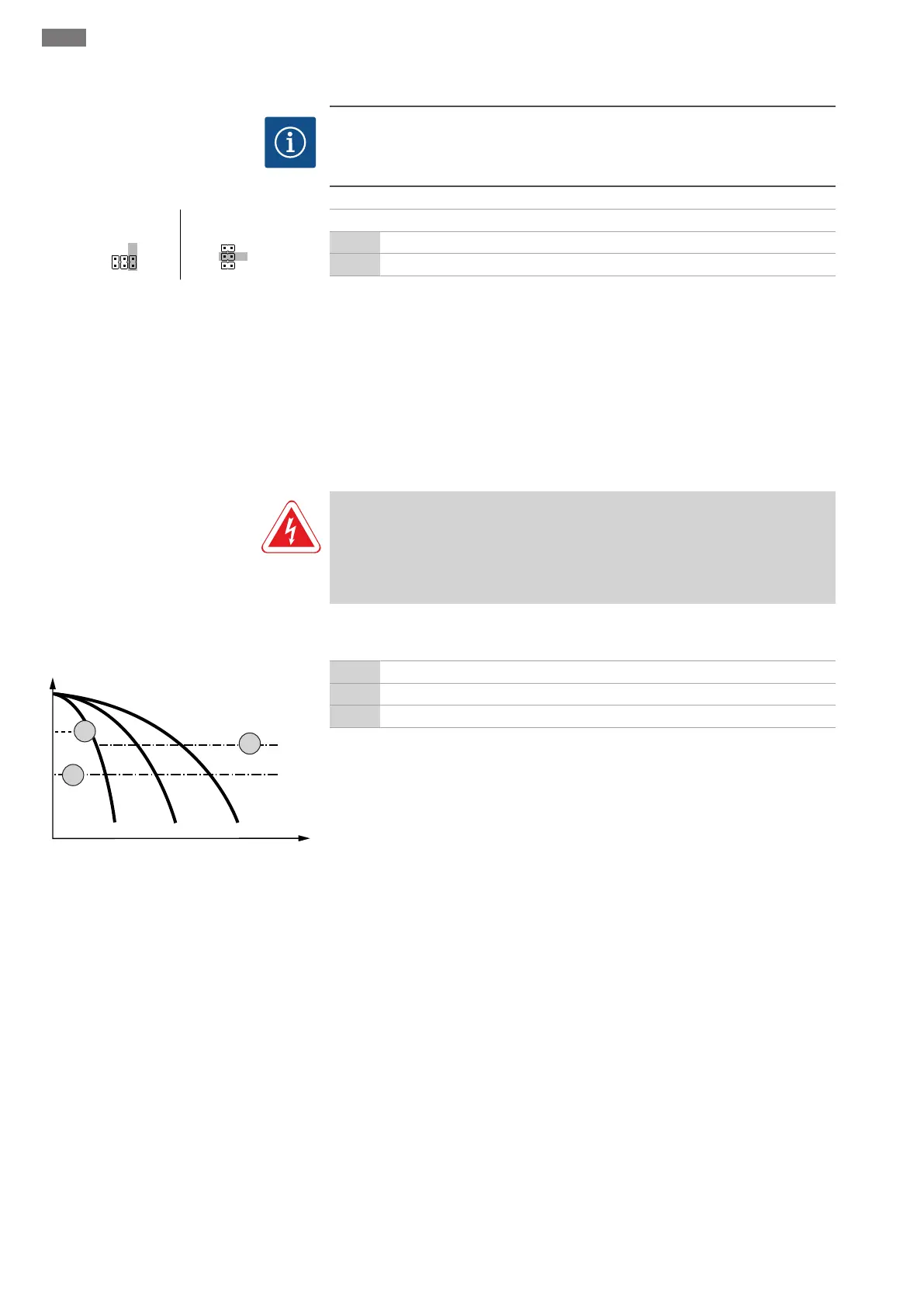

Fig.23: Functional diagram for Control EC-

Booster

2 Activation threshold

3 Deactivation threshold for base-load pump

4 Deactivation threshold for peak-load pumps

During normal operation, the system maintains a pressure in the range between the ac-

tivation and deactivation thresholds. Control is carried out as two-position control. A

pressure sensor measures the actual pressure value. If the pressure falls below the ac-

tivation threshold, the base-load pump switches on. Depending on the power require-

ment, the peak-load pumps are activated one by one. If the deactivation threshold for

the peak-load pumps is exceeded, the system turns off the peak-load pumps one by

one. If the deactivation threshold for the base-load pump is exceeded, the system turns

off the base-load pump. During operation, a visual indicator appears on the LCDdisplay

and the green LED lights up. To optimise pump running times, pump cycling is carried

out regularly.

In the event of a fault, the system automatically switches to a different pump. The error

code is shown on the LCD display and the red LED lights up. The outputs for the collect-

ive fault signal (SSM) and individual fault signal (ESM) are activated.

If the low water level in the break tank (dry-running protection) is reached, all pumps

are switched off. The error code is shown on the LCD display and the red LED lights up.

The output for the collective fault signal (SSM) is activated.

Loading...

Loading...