Transportation and storage en

Installation and operating instructions Wilo-Control EC/ECe-Booster 53

Outputs

▪Potential-free contacts:

– 1x changeover contact for collective fault signals

– 1x changeover contact for collective run signals

– 1x NC contact per pump for individual fault signals

– 1x NO contact per pump for individual run signals

▪Inputs for pump control:

– Control ECe-Booster: 1x analogue output per pump (0–10V) for the configured

speed setpoint

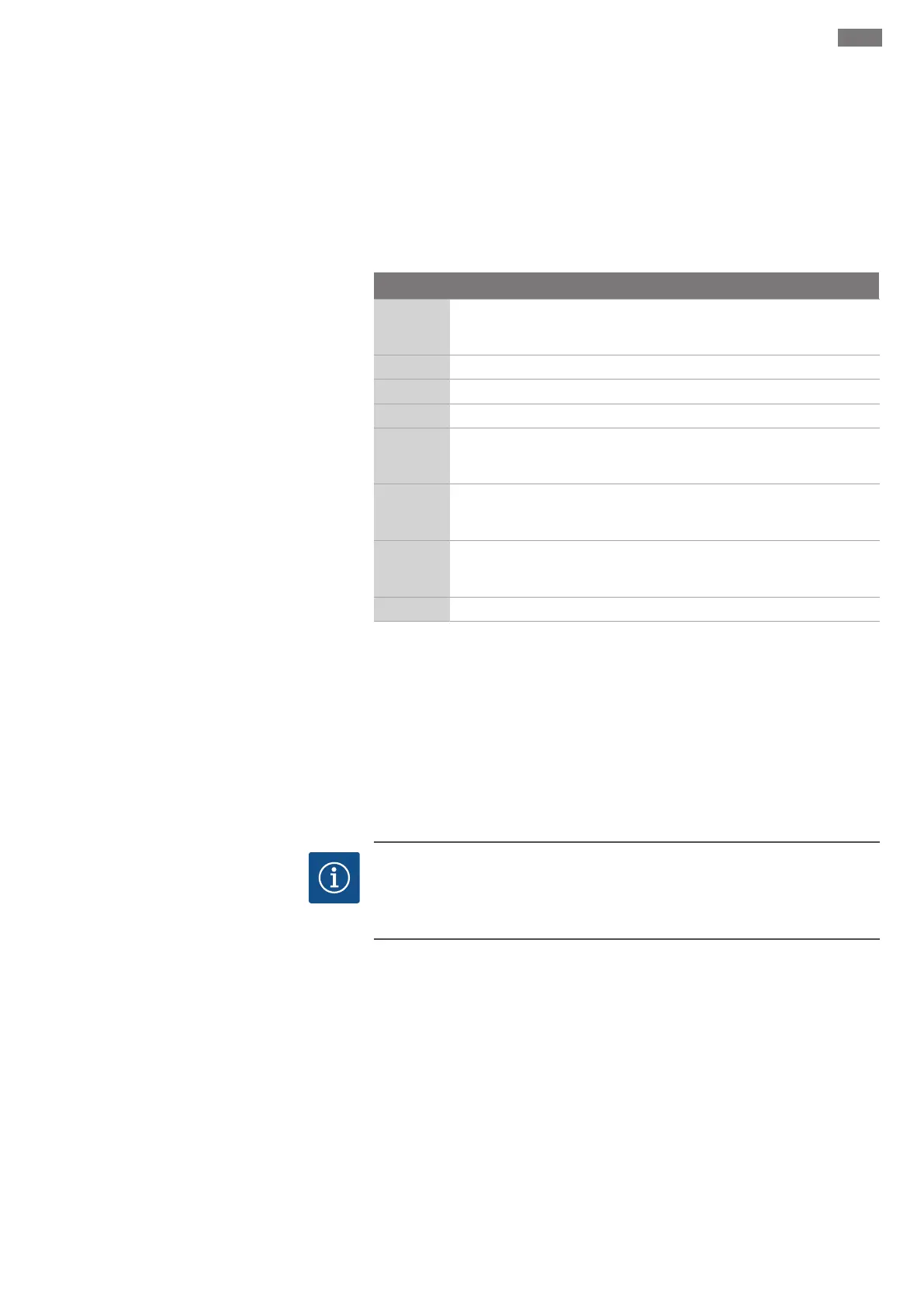

4.5 Type key

Example: Wilo-Control ECe-B 2x12A-T34-DOL-WM

ECe

Version with Easy Control switchgear:

- EC = switchgear for fixed-speed pumps

- ECe = switchgear for electronically controlled variable-speed pumps

B

Control for pressure-boosting systems

2x

Max. number of pumps that can be connected

12A

Max. rated current per pump in amperes

T

Mains connection:

M = alternating current (1~)

T = three-phase current (3~)

34

Rated voltage:

- 2 = 220–230V

- 34 = 380–400V

DOL

Pump activation type:

- DOL = direct on line

- SD = star-delta

WM

Wall fixation

4.6 Scope of delivery

Control EC-Booster

▪Switchgear

▪Installation and operating instructions

Control ECe-Booster

▪Switchgear

▪Installation and operating instructions

▪Circuit diagram

4.7 Accessories

▪Float switch/pressure switch for dry-running protection

▪Pressure sensor (4–20mA) for system control

NOTICE

Accessories installed as required

If the switchgear is delivered with a pressure-boosting system, the accessories may

be pre-installed. Please check the order confirmation for further information.

5 Transportation and storage

5.1 Delivery

After receiving the shipment, check it immediately for defects (damage, completeness).

The transport company or the manufacturer must be notified of any defects the day the

shipment is received, and the damage noted on the freight documentation. Claims can-

not be asserted if the notification of defects takes place at a later date.

5.2 Transport

▪Clean switchgear.

▪Close housing apertures, ensuring they are sealed watertight.

▪Impact-resistant and watertight packaging.

Replace soaked packaging immediately!

Loading...

Loading...