the eight air bags is coupled with a Magnum gas shock absorber. The suspen-

sion control arms are attached to the frame through bushings, which require no

lubrication.

The suspension ride height is preset and will maintain the proper ride height

automatically, regardless of the load.

The air compressing system on the motorhome is comprised of several

items: an air compressor, air governor, air dryer, a front air tank and a rear air

tank. The compressed air system operates several items, some of which include

brakes, suspension, air horns, air gauge and stepwell cover. The air system is

charged by a gear driven air compressor mounted on the engine. As engine

speed increases, compressed air output increases. When the air is compressed,

heat is generated. Heat dissipates as the air is discharged from the compressor.

Moisture condenses in the compressed air as it cools. The moisture laden air

then enters an air dryer where the air is filtered. The filtered air charges the

front air tank. The front air tank is divided in two halves: a wet side and a dry

side. The compressed air enters the wet side before entering the dry side. A

discharge line from the dry side of the front air tank charges the rear air tank.

The discharge lines use inline check valves to prevent back flow of compressed

air.

The pneumatically operated items are divided into two categories: brakes

and accessory air. Brakes have full use of supplied air pressure. Accessory air

items such as air horns or stepwell covers receive air through pressure protec-

tion valves (PPV). The PPV will not allow compressed air flow until approxi-

mately 60 psi. In the event of an air system problem the pressure protection

valve will leave a reserve air charge for braking. Pressure protection valves are

installed for safety.

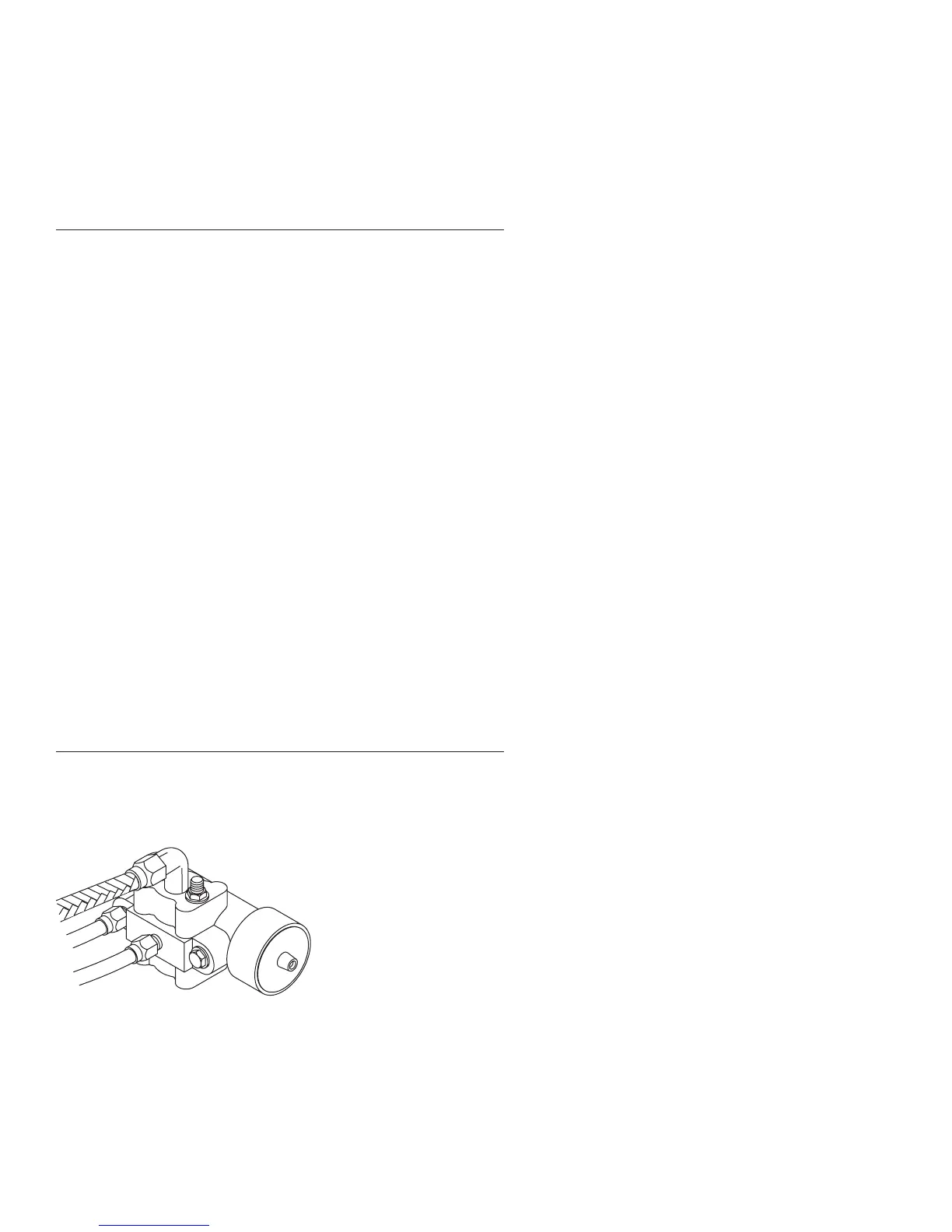

The air governor is located in the engine compartment. The air

governor performs two functions: regulating the air compressor to

cut-in and cut-out keeping the air system in the specified operating

range of 105-120 psi; sending an air “purge” signal to the Air Dryer.

Cut-in pressure of approximately 105 psi is factory preset from the

governor manufacturer and is not adjustable. Cut-out pressure is cali-

brated to 120 psi. When cut-out pressure is reached the governor will

send an air purge signal to the Air Dryer. This opens the purge port of

the Air Dryer, expelling moisture. The purge action of the Air Dryer

is identified by the short release of air at the rear of the motorhome.

Chassis Information

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

WINDSOR

10•258

AIR GOVERNOR

AIR SUPPLY

SYSTEM

Loading...

Loading...