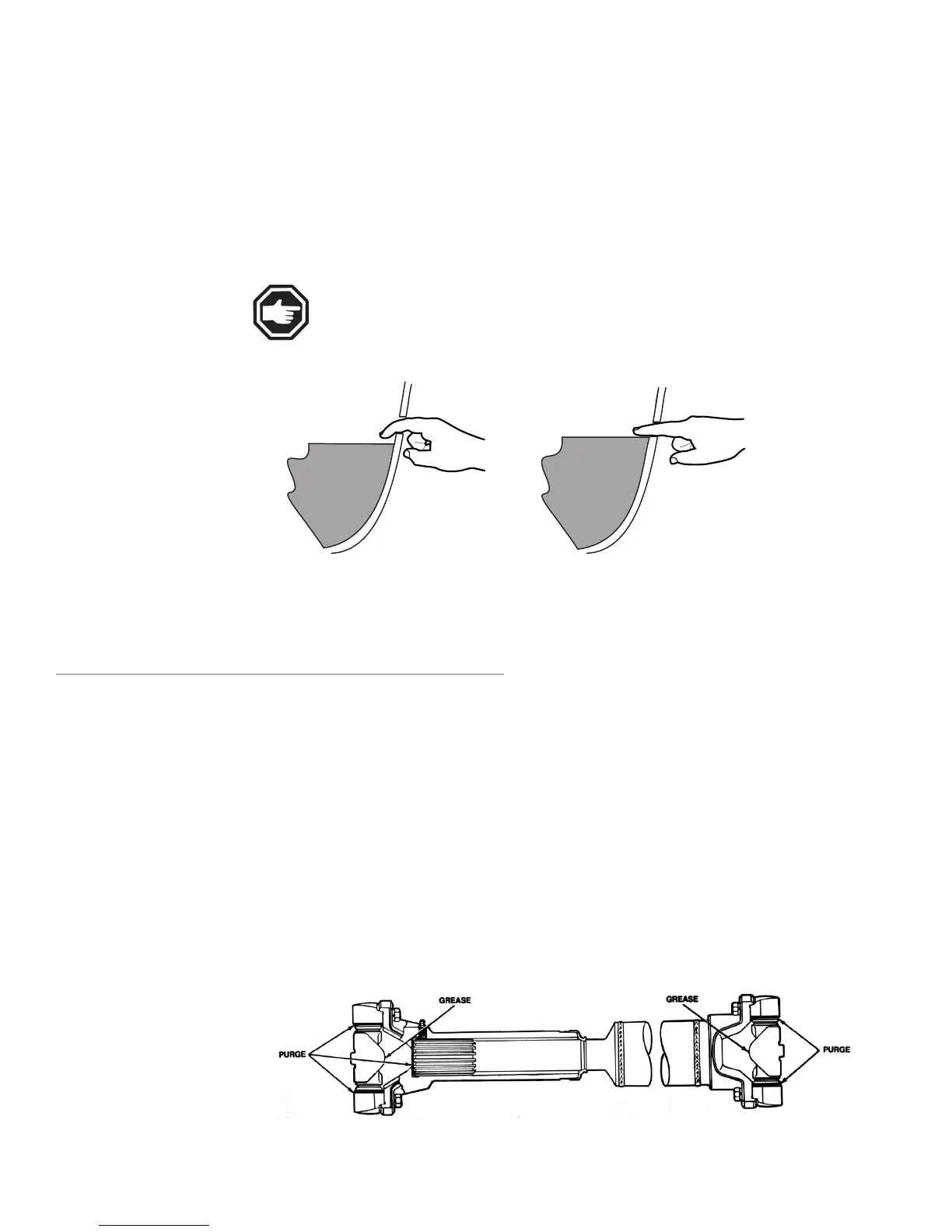

Proper Drive Axle Lubricant Level

• Regular inspection of the drive axle lube levels is an essential maintenance pro-

cedure.

• The lubricant should be level with bottom of the hole.

• Important: The lube level close enough to the hole to be seen or touched is not

sufficient. The lube must be level with the hole.

• Your differential is filled with API GL-5 or MT-1 type gear lubricant, Pennzoil

Gear Plus Super-EW 75w-90.

NOTE: When checking the lube level also check the housing breathers.

Clean the breathers if dirty or replace them if damaged.

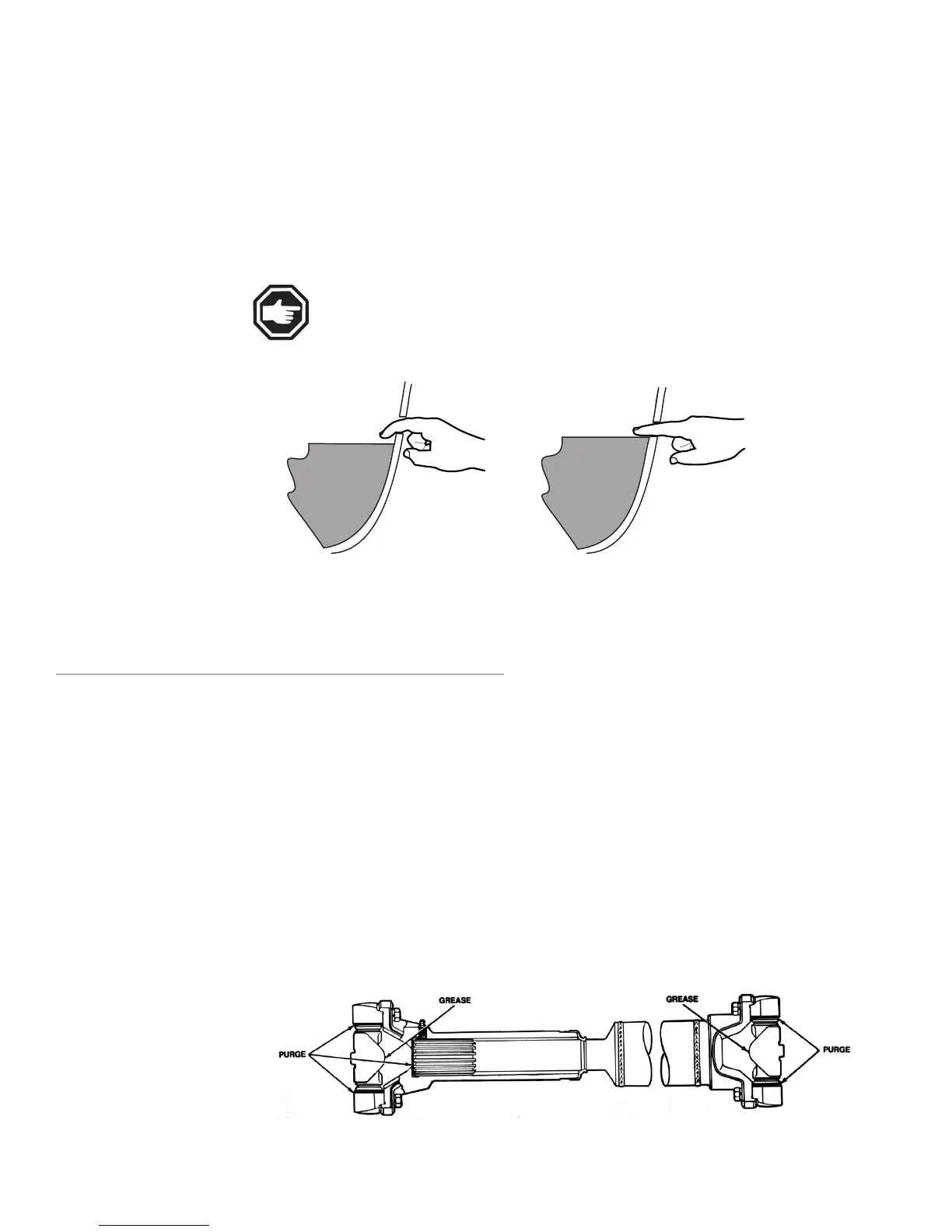

Greasing the Driveline Universal Joint:

1. Check the driveline for looseness. If loose, service the driveline as necessary.

2. Apply the specified grease at the grease fitting on the universal joint. Apply

grease until the new grease purges from all the seals.

3. If the new grease does not purge at the seals loosen the bearing cap bolts and

regrease until all four caps purge. If the new grease still does not purge replace

the universal joint.

Greasing the Driveline Slip Yoke and Splines:

1. Check the driveline for looseness. If loose, service the driveline as necessary.

2. Cover the air hole so that grease can flow easily to the seal. Apply the speci-

fied grease at the grease fitting on the slip yoke. Apply grease until new grease

purges from the air hole in the end of the slip yoke. Greasing Intervals-10,000

miles or annually.

Chassis Information

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

WINDSOR

10•300

DRIVE AXLE

LUBRICANT

Incorrect Oil Level

Correct Oil Level

DRIVELINE

Loading...

Loading...