Planning

26 | WOLF GmbH 3066501_201910

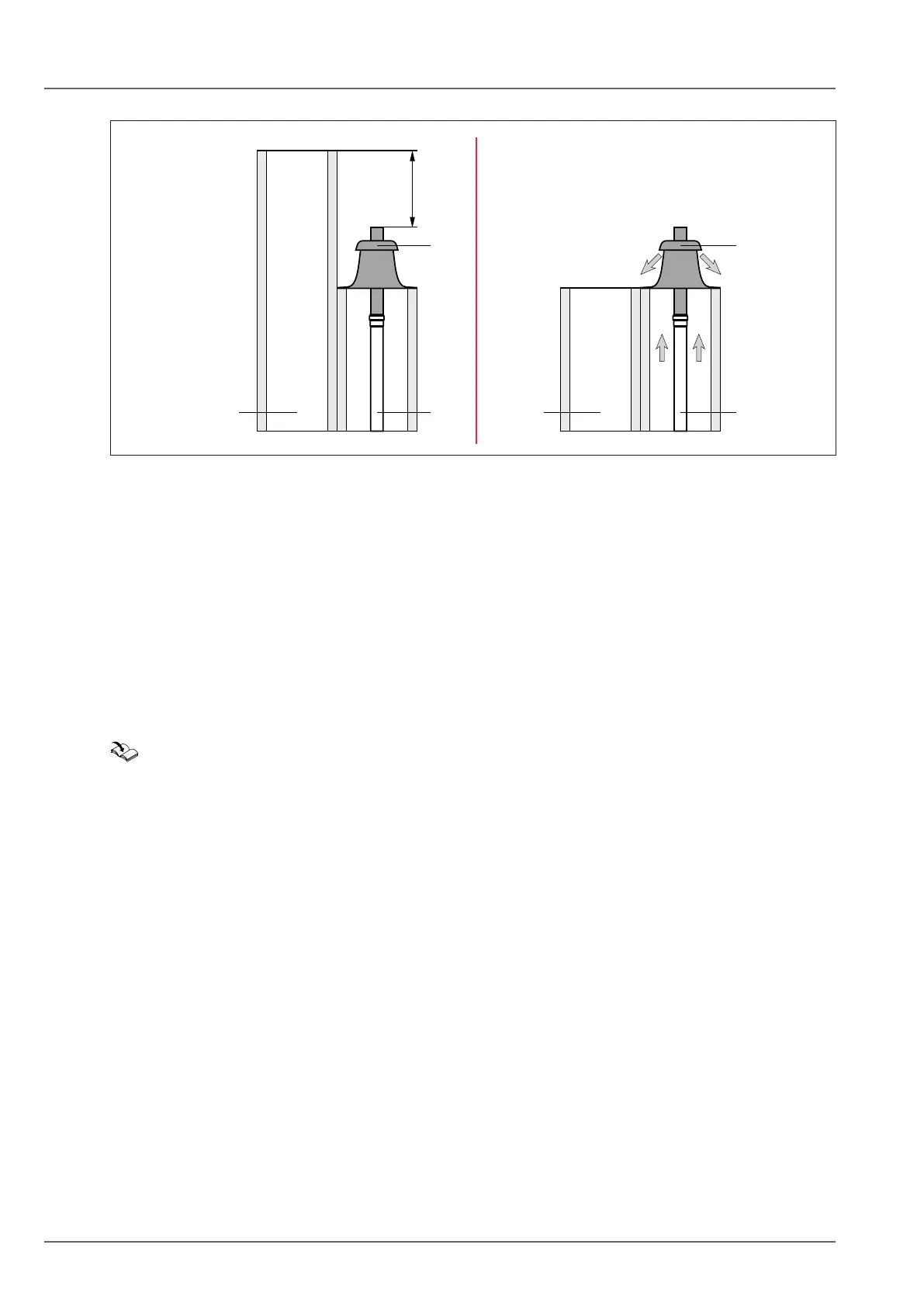

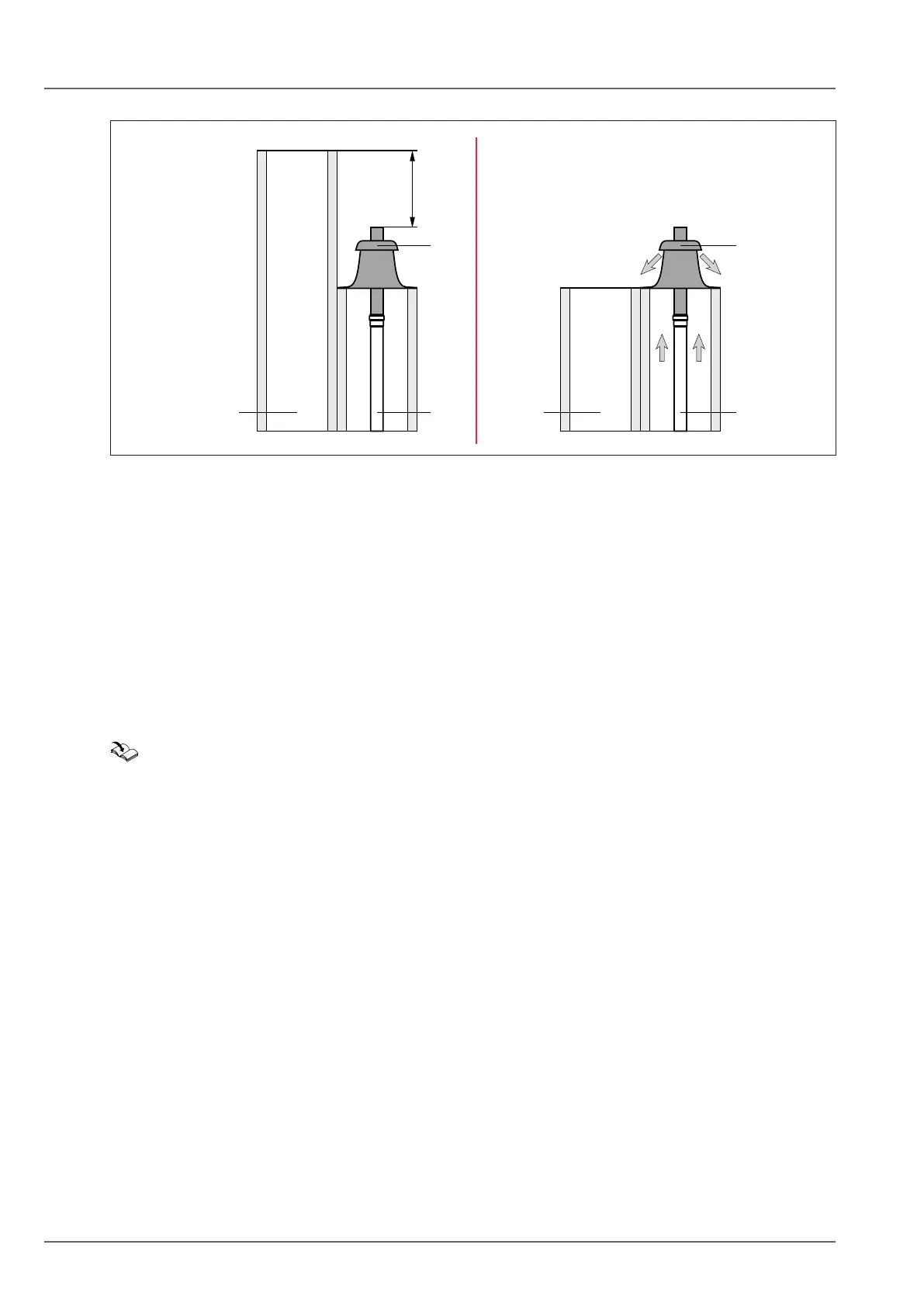

Moisture-resistantuewithtwo-ormultiple-draughtchimneys

1000

AB

Fig. 4.7 Twin duct chimney

A Open ue and room sealed operation

B Open ue operation

q Chimney T400

w Polypropylene system up to 120°C, CE

approved

e Shaft cover from the WOLF product range

r Stainless steel shaft cover from the WOLF

product range

4.7 Cascade operation

Up to four heat generators (with the same output) can be cascaded.

– Cascade 4 x COB-2-29 (18.9 - 115.2 kW) or

– Cascade 4 x COB-2-40 (27.4 - 154.0 kW)

4.7.1 Controlconguration

KM-2 cascade module installation and operating instructions for contractors

MM-2 mixer module installation and operating instructions for contractors

BM-2 programming unit installation and operating instructions for contractors

The heat generators have control PCBs with functions which are tailored to the WOLF control modules.

Conguration only in conjunction with a KM-2 cascade module.

The KM-2 cascade module controls:

– the header ow (based on the load)

– one mixer circuit

– one DHW cylinder circuit

The MM-2 mixer module controls:

– one additional mixer circuit

– one radiator circuit

A BM -2 programming unit with wall mounting base can be used as a remote control unit for each

mixer module.

4.7.2 Directly heated DHW cylinder

The directly heated DHW cylinder can be connected downstream of the hydraulic separation or via a low

loss header.

Cylinder heating is controlled via the cascade controller type KM-2, to which a cylinder primary pump and

the electronic cylinder sensor are connected.

Loading...

Loading...