Appendix

3066501_201910 WOLF GmbH | 85

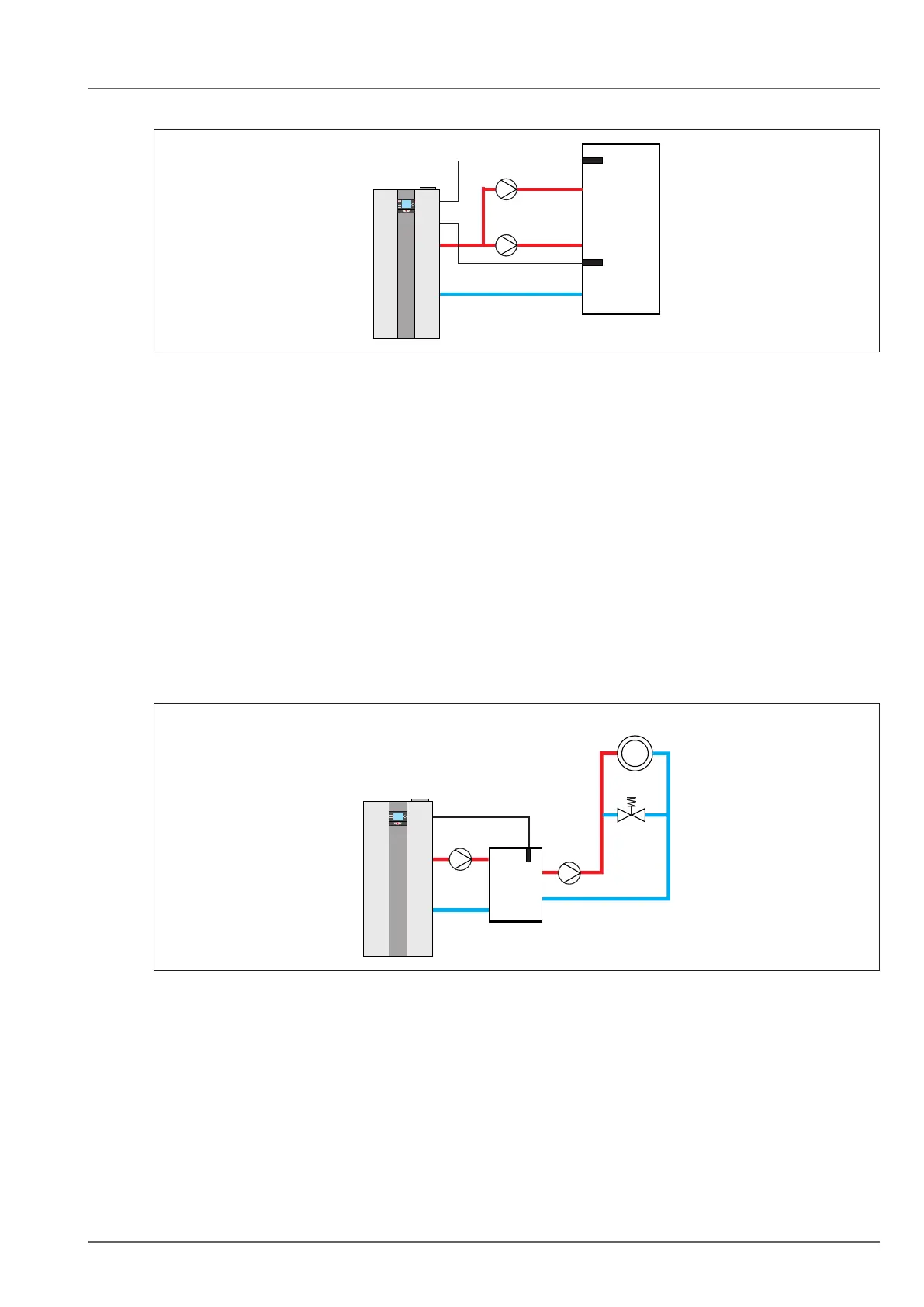

BSP cylinder with header sensor

Fig. 12.8 Systemconguration11-BSPcylinderwithheadersensor

q Input: Cylinder temperature sensor

w Input E2: Header temperature sensor

e Cylinder primary pump

r Feed/heating circuit pump

t Cylinder temperature sensor

y Header temperature sensor

– Burner starts subject to demand from the header temperature control (heating mode) or in case of

cylinder demand.

– Feed/heating circuit pump enabled as a feed pump (heating mode only). Not activated during cylinder

heating.

– Header temperature control (heating mode only)

– Input E2: Header sensor (heating mode only)

– In case of cylinder heating, the reference temperature is provided by the boiler sensor.

– Heating circuit with MM-2! see hydraulic schemes no. 16-52-018-003, 16-52-018-005 and

16-52-018-006

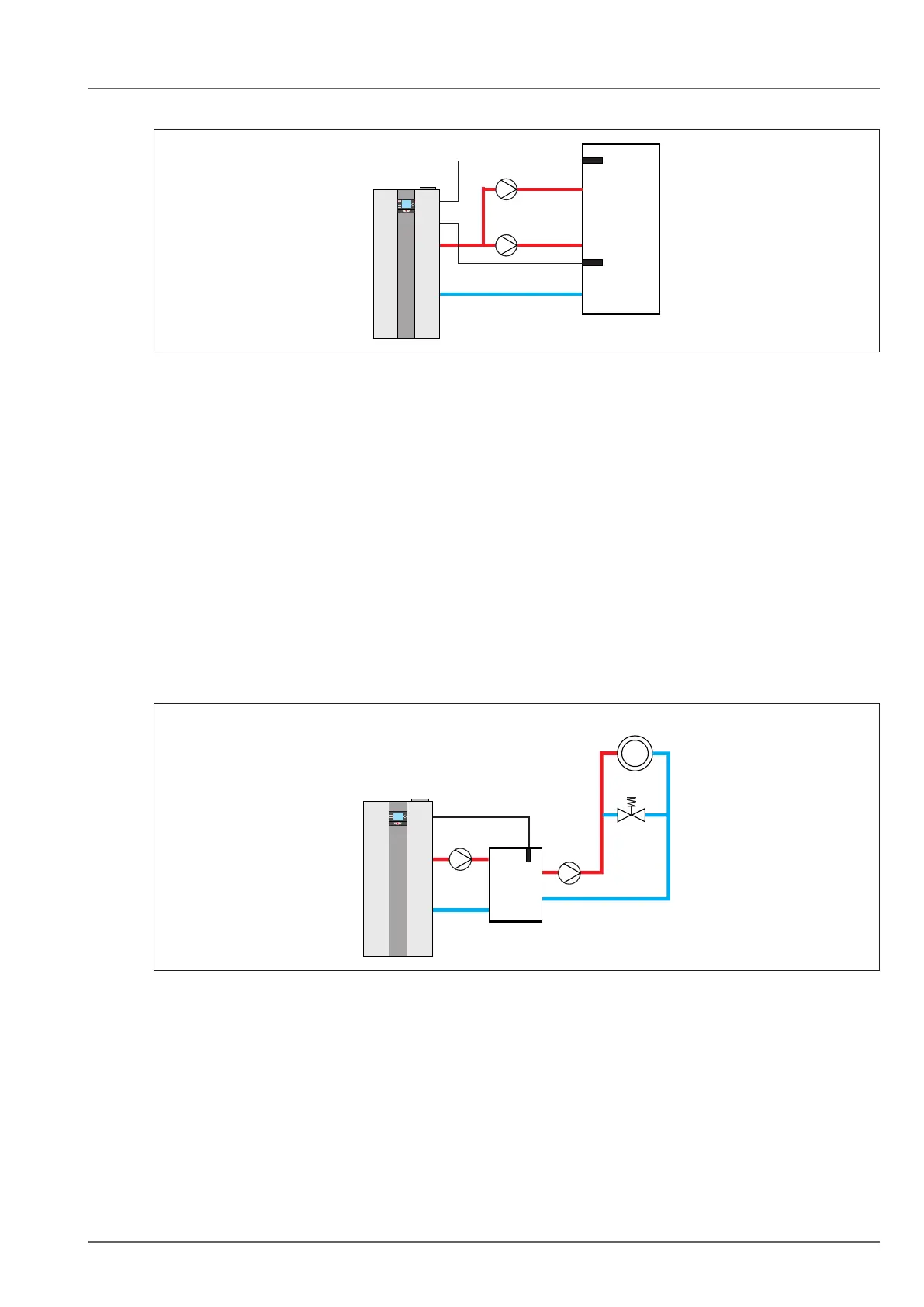

12.3.4 Systemconguration12

Low loss header with header sensor + direct heating circuit (A1)

Fig. 12.9 Systemconguration12-Lowlossheaderwithheadersensor

q Input E2: Header temperature sensor

w Feed/heating circuit pump

e Header temperature sensor

r A1 = heating circuit pump

t Direct heating circuit

– Burner starts subject to demand from the header temperature control

– Feed/heating circuit pump enabled as a feed pump for header demand

– Header temperature control

– Input E2: Header sensor

– Parameter 08 (T-Flowmax): 90°C

– Parameter 22 (max. boiler temp.): 90°C

– Parameter 14 (output A1): HCP

Loading...

Loading...