Installation

3066501_201910 WOLF GmbH | 35

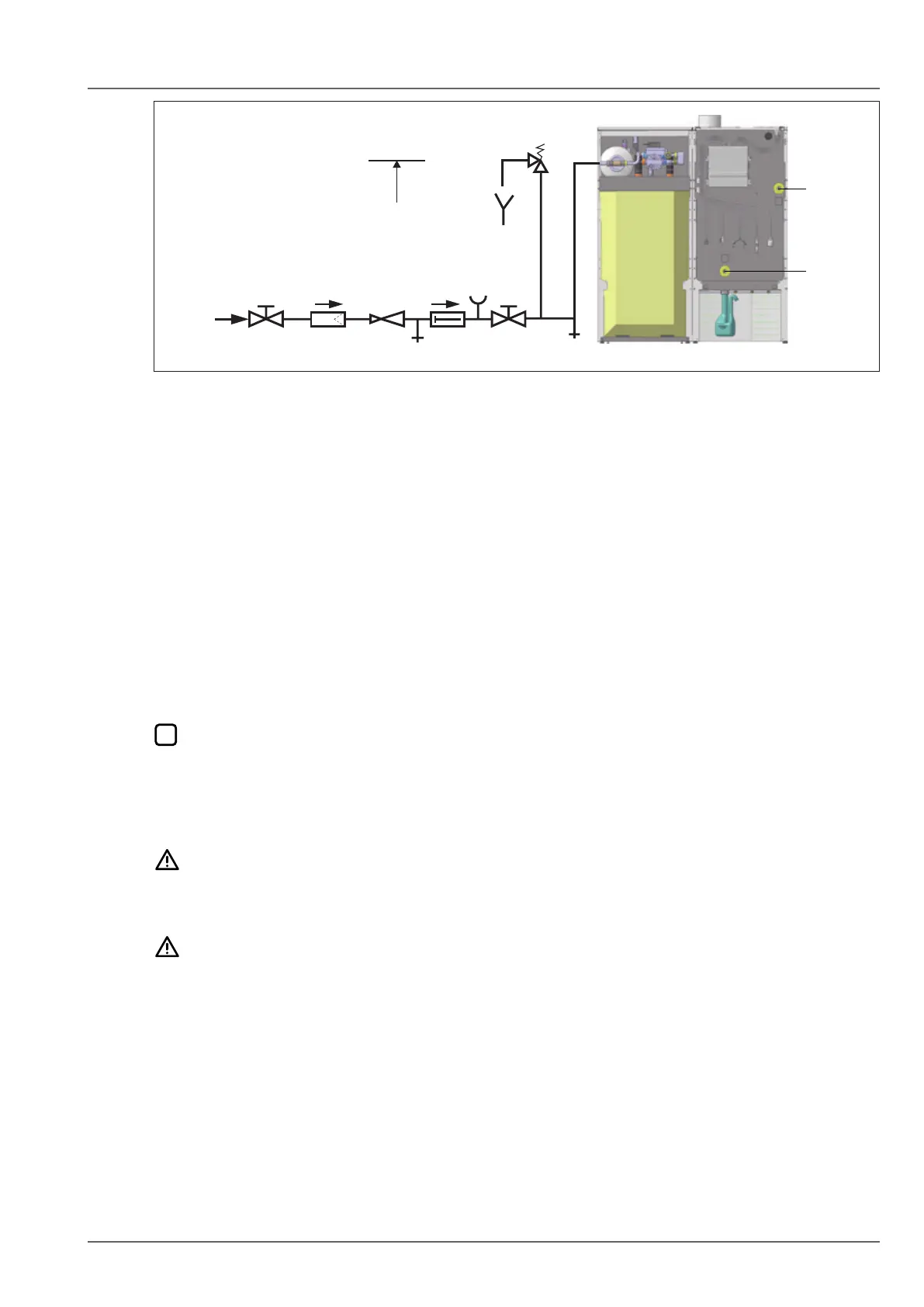

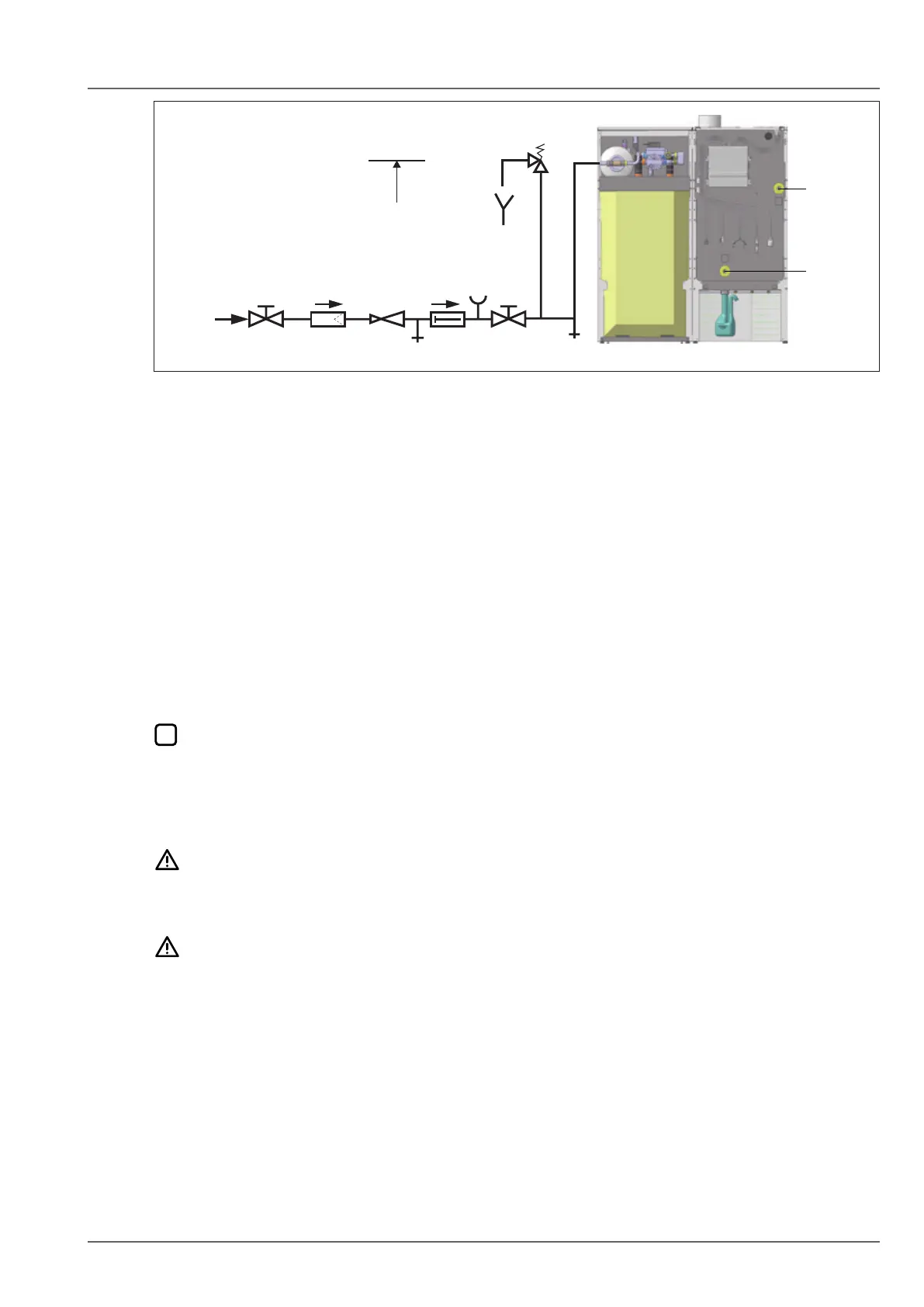

Fig. 5.10 Cold water connection to DIN 1988

q Cold water supply

w Shut-off valve

e Drinking water lter

r Pressure reducing valve

t Drain

y Non-return valve (individually tested)

u Pressure gauge connection

i Shut-off valve

o Above top edge of the cylinder

a Safety valve (individually tested)

s Heating ow

d Heating return

5.7 Connecting the oil line

► Connect the system.

► A lter/air vent valve combination with an integrated shut-off valve from the WOLF product range must

be installed.

► Check the oil line in accordance with TRÖl for the following:

– fault-free condition

– properly installed

– no leaks

This inspection is performed in the following cases:

– Before commissioning

– For underground oil lines, before they are covered

– After work on the oil lines (except for oil lter changes)

5.7.1 Connectingthelter/airventcombination

CAUTION

Oil leak!

Drinking water may be contaminated by hazardous substances.

► Install the oil line with the system disconnected from the power supply.

NOTE

Contaminants in the oil line

System damage

► Flush the oil line before commissioning!

► Route the oil line through the back panel.

✔ Oil line projects no more than 90 cm from the casing.

► Secure the lter/vent combination (integrated shut-off valve) and retainer to the positions provided for

this.

5.7.2 Connecting the anti-lift valve

► Connect anti-lift valve to output A1

► Set A1 (ext. fuel valve) parameter (7.2.7 HG14: Function output A1).

If output A1 is already being used (e.g. for a DHW circulation pump),

Loading...

Loading...