2. Inspection and adjustment

90

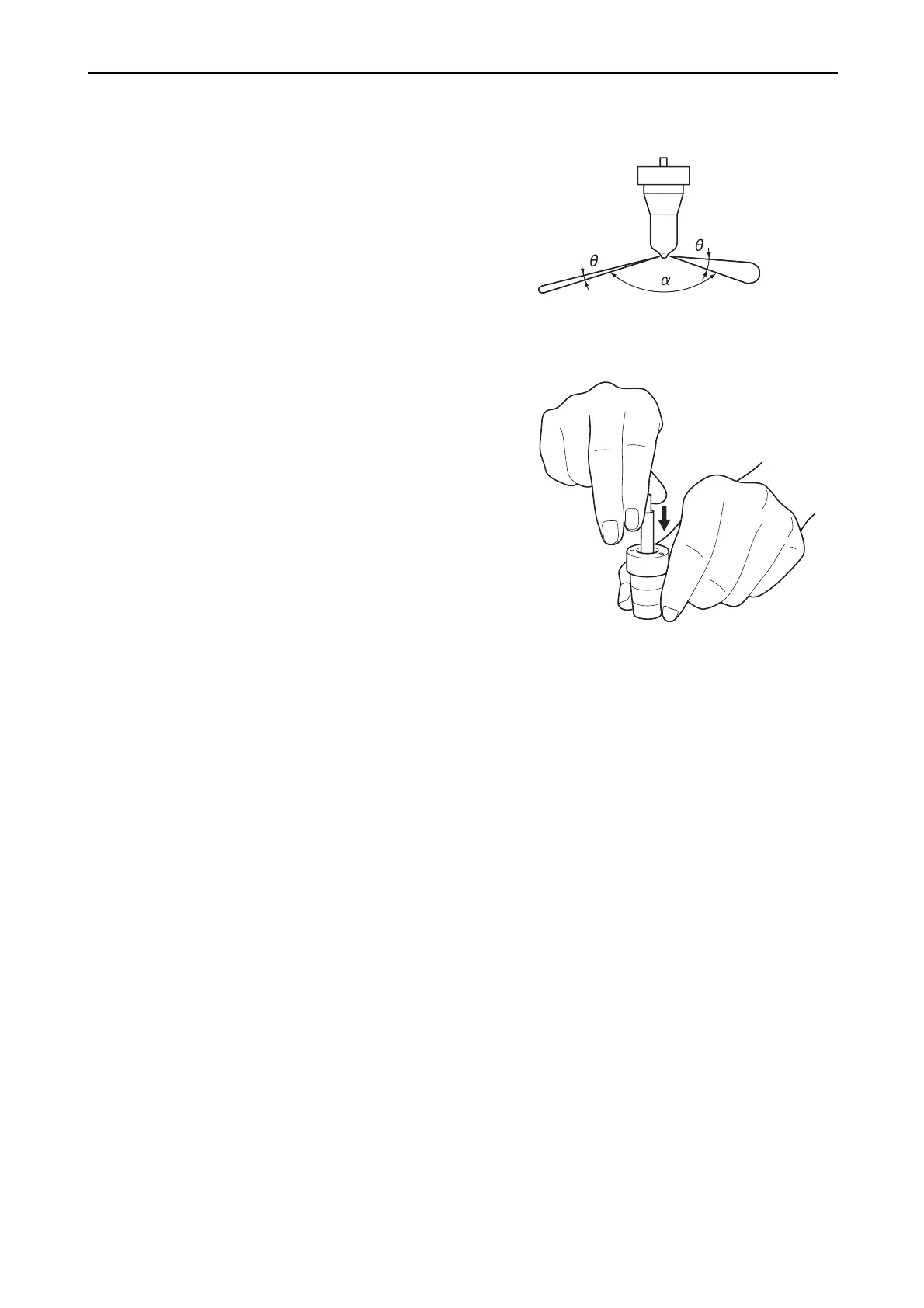

b) Spray and injection states

• Operate the nozzle tester lever at a rate of

once or twice a second and check no

abnormal injection.

• If normal injection as shown below cannot

be obtained, replace the fuel injection valve.

• No extreme difference in angle (θ).

• No extreme injection angle difference (α).

• Finely atomized spray.

• Excellent spray condition.

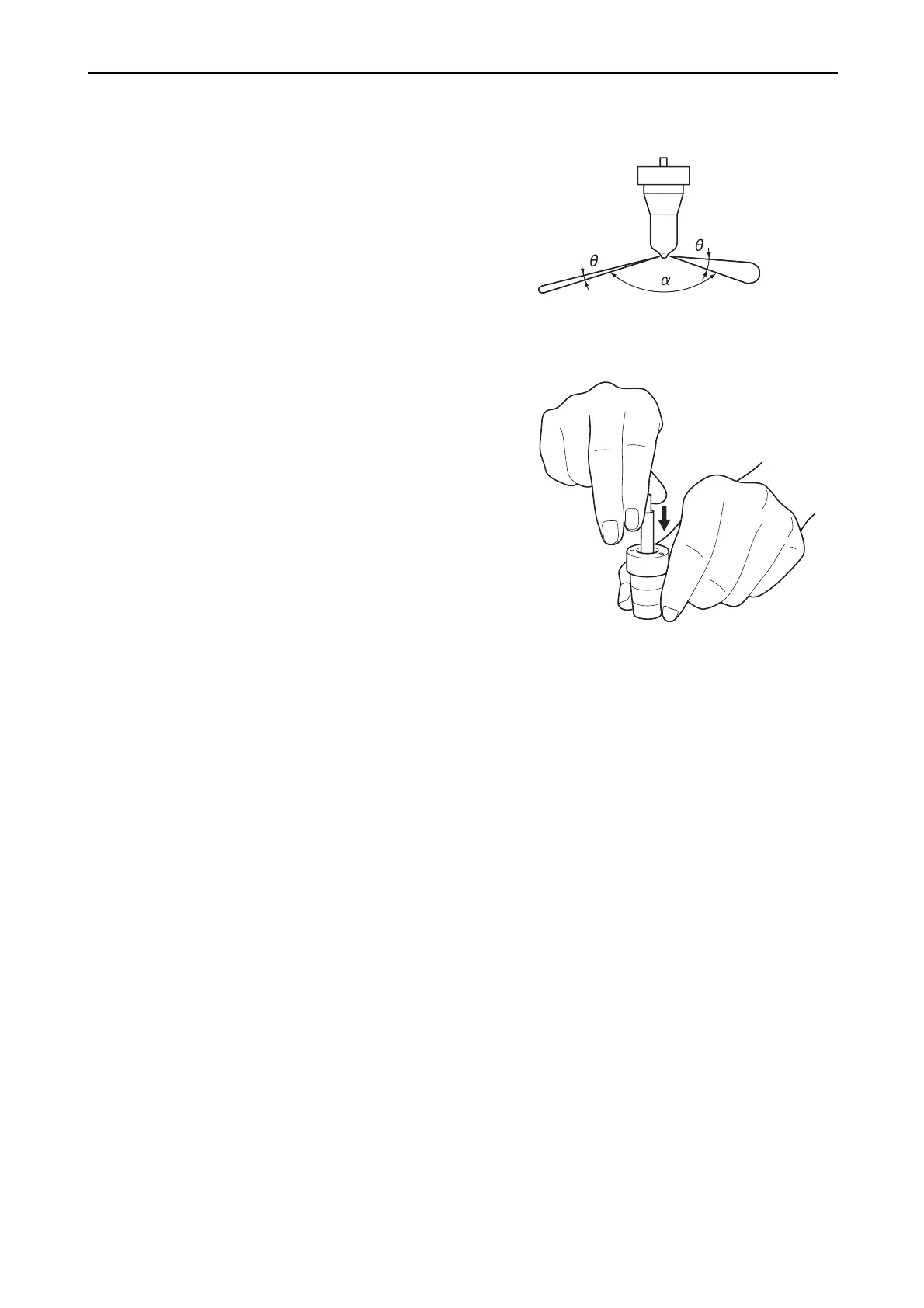

3) Nozzle valve sliding test

Wash the nozzle valve in clean fuel oil. Place

the nozzle body vertically and insert the

nozzle into the body to about 1/3 of its length.

The valve is normal if it smoothly falls by its

own weight into the body. In case of a new

nozzle, remove the seal peel, and immerse it

in clean diesel oil or the like to clean the inner

and outer surfaces and to thoroughly remove

rust-preventive oil before using the nozzle.

Note that a new nozzle is coated with rust-

preventive oil and is pasted with the seal peel

to shut off outer air.

(3) Check the impeller of the seawater

pump

The impeller must be replaced with new one

periodically (every 1000 hrs or four years

whichever comes first).

Refer to 2.2.4 (5) for the procedure.

(4) Clean and check the water passages

When it is used for a long time, cleaning of the

seawater passages is periodically necessary,

because trash, scales, rust, and so on collect

in the seawater passages and the cooling

performance declines.

(a) Cleaning and inspection of seawater rubber

hoses.

1) Check the dust and trash inside the hoses. If

necessary, clean it.

2) Replace the used hose clips with new ones, if

necessary.

010631-00E

Abnormal

010632-00X

Loading...

Loading...