2. Inspection and adjustment

91

(b) Heat exchanger (fresh water cooler) inspection

Inspect the fresh water cooler by the following

procedure. The intercooler only for 4JH4-HTE

can be inspected by the same way.

1) Cooler core inspection

a) Inspect the inside of the tubes for rust or

scale buildup from seawater, and clean with

a wire brush if necessary.

Note:

Disassemble and wash when the coolant

temperature reaches 85°C.

b) Check the joints at both ends of the tubes

for looseness or damage, and repair if

loose. Replace if damaged or corroded.

c) Check tubes and replace if leaking.

d) Clean any scale or rust off the outside of the

tubes.

2) Heat exchanger body water leakage test

a) Check heat exchanger body and side cover

for dirt and corrosion. Replace, if excessively

corroded, or cracked.

b) Inspect seawater and fresh water inlets and

outlets, retighten any joints as necessary

and clean the insides of the pipes.

c) Check the exhaust gas intake flange and

line, and replace if corroded or cracked.

3) Heat exchanger body water leakage test

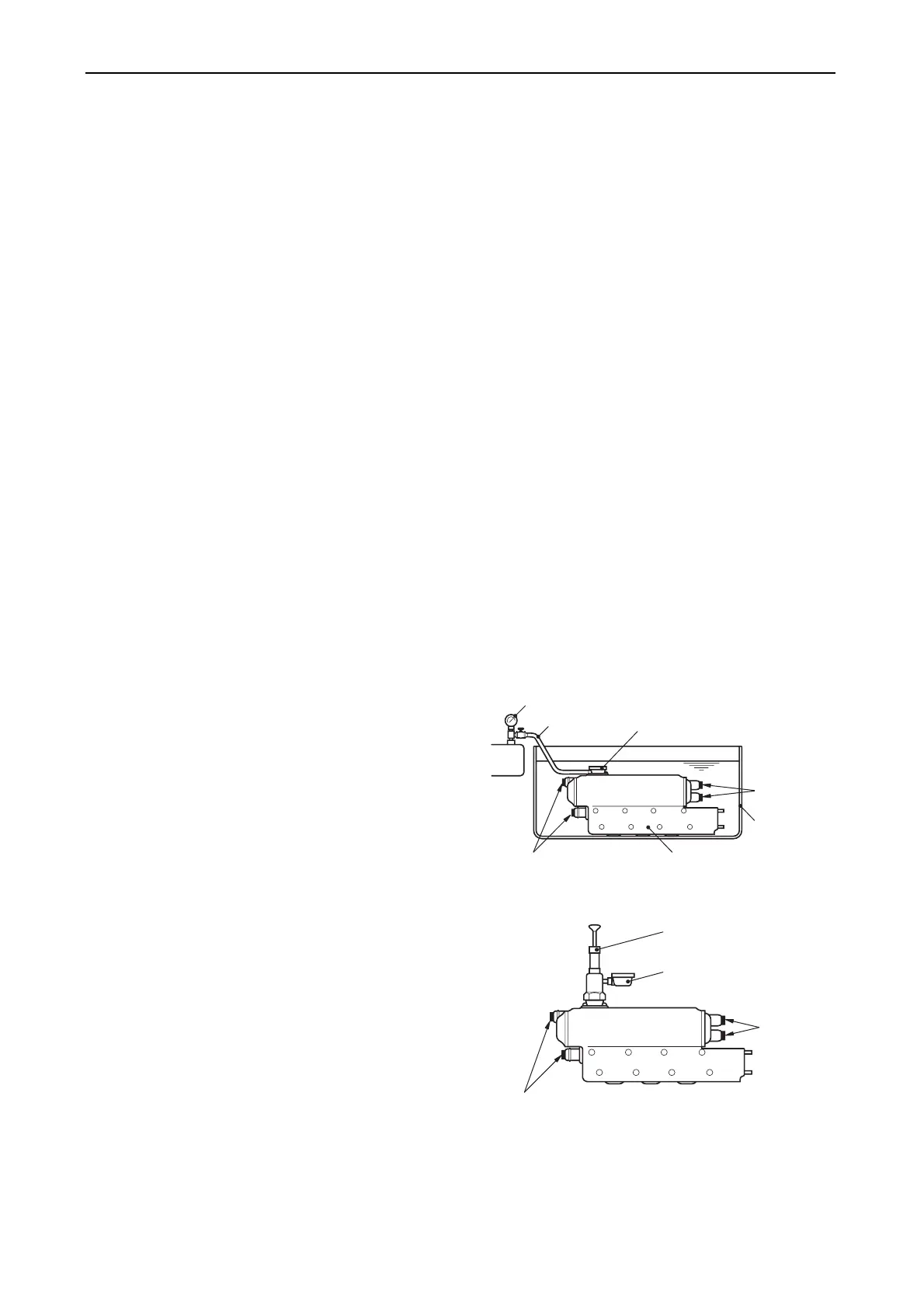

a) Compressed air/water tank test

Fit rubber covers on the fresh water and

seawater inlets and outlets. Place the heat

exchanger in a water tank, feed in

compressed air from the overflow pipe and

check for any (water) leakage, (air bubbles).

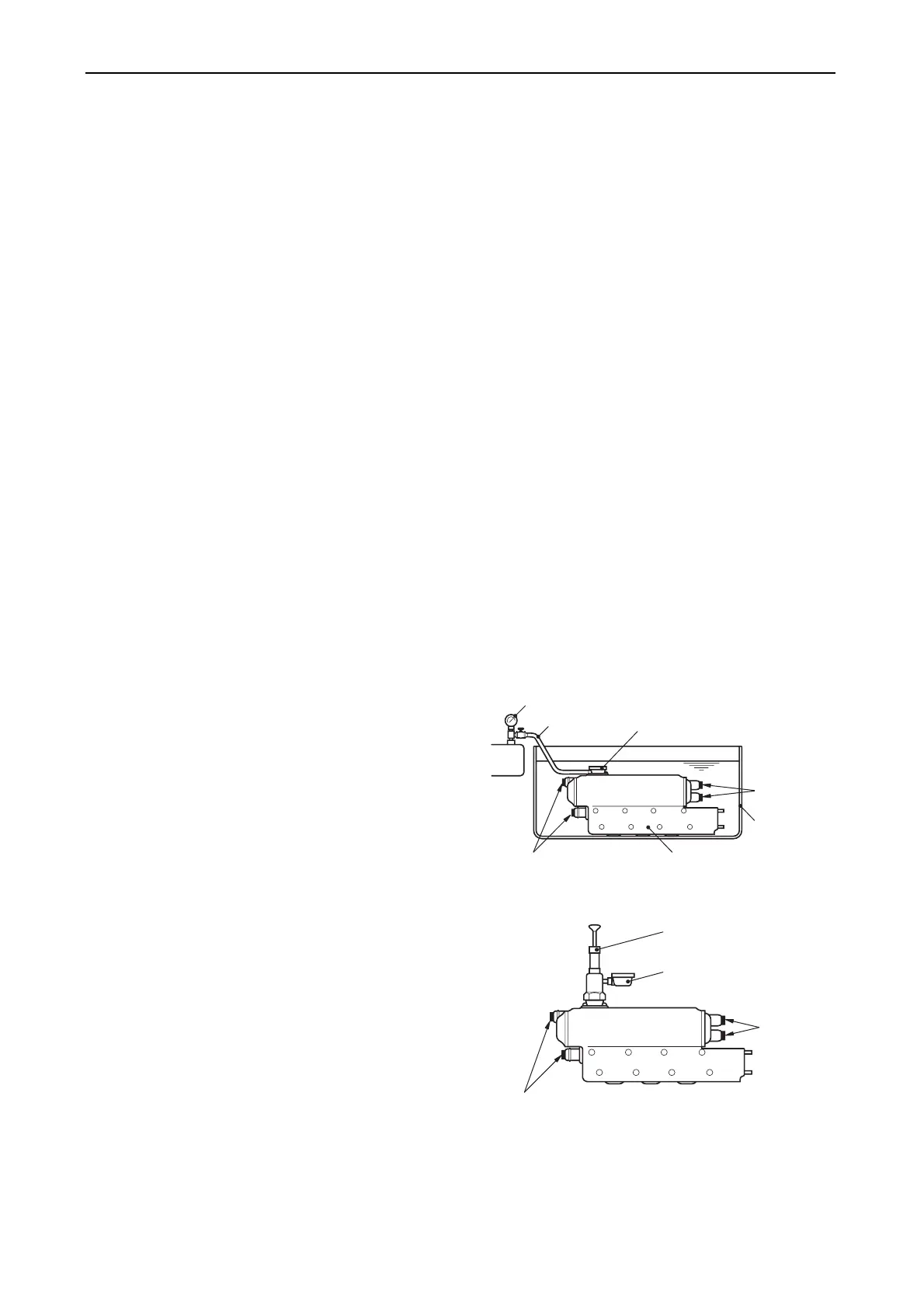

b) Use of the tester

Fit the fresh and seawater inlets and outlets

with rubber covers and fill the fresh water

tank with fresh water. Fit a pressure cap

tester in place of the pressure cap, operate

the pump for one minute and set the

pressure at 0.15 MPa (1.5 kgf/cm

2

, 21.33

lb/in.

2

). If there are any leaks the pressure

will not rise. If there are no leaks the

pressure will not fall.

Pressure gauge

Rubber

cap

Test tank

Rubber cap

Air hose

Filler cap

Heat exchanger

010633-00E

Pressure tester

Pressure gauge

Rubber

cap

Rubber cap

010634-00E

Loading...

Loading...