2. Inspection and adjustment

64R1

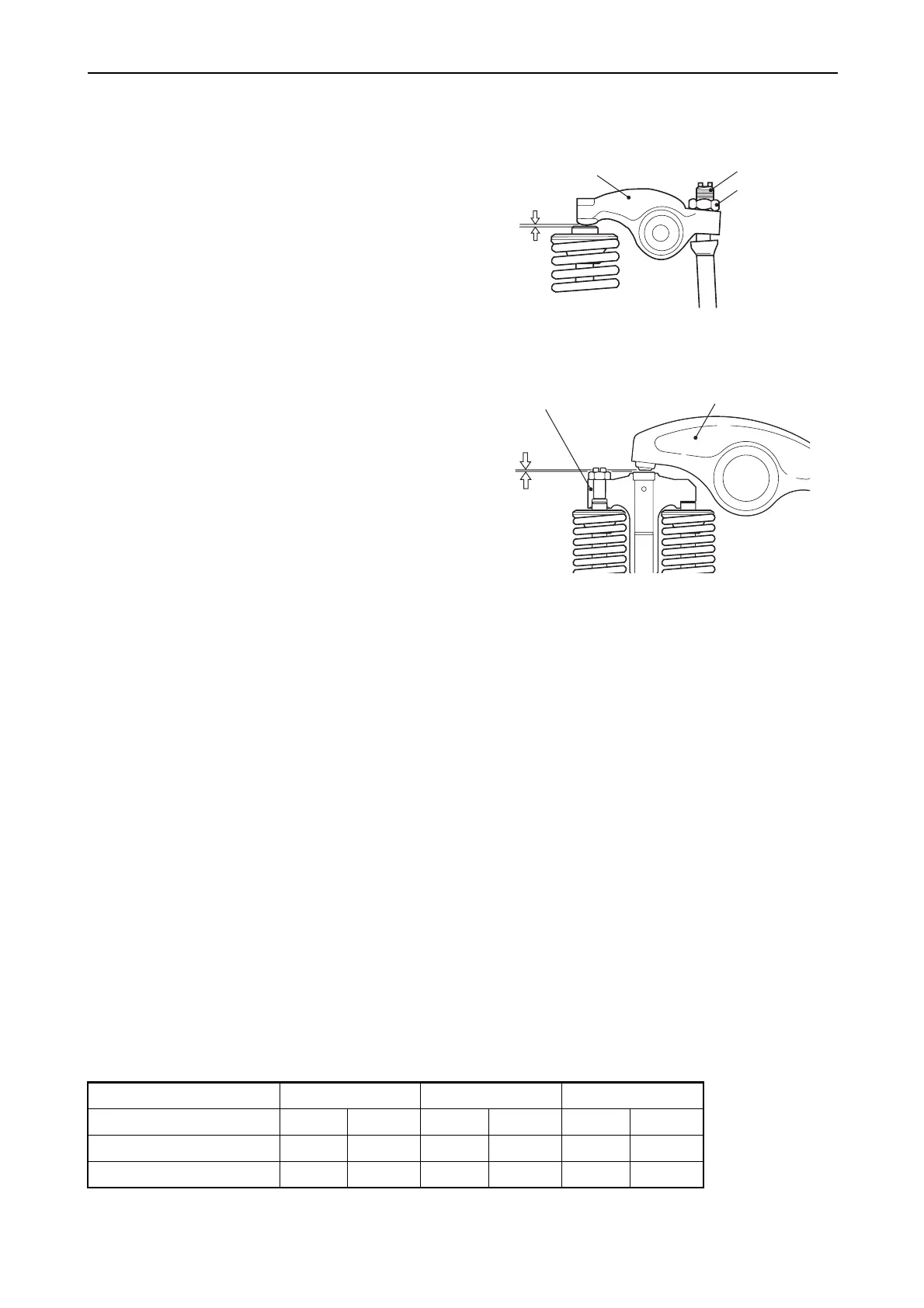

c) Valve clearance measurement and

adjustment

(c-1) For 2 valves system (3JH4E, 4JH4E),

insert a thickness gage between the

rocker arm and valve cap, and record

the measured valve clearance.

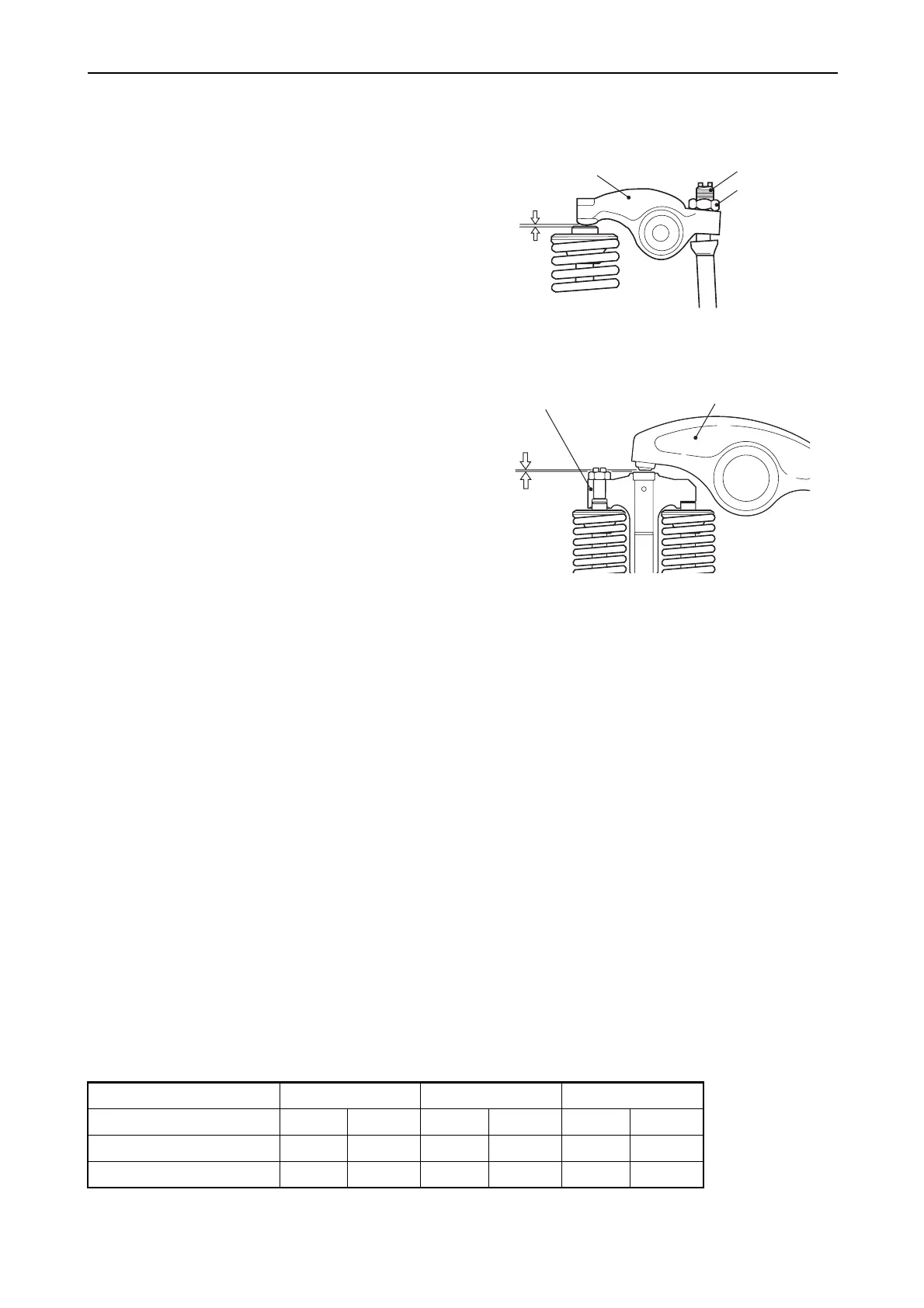

(c-2) For 4 valves system (4JH4-TE, 4JH4-

HTE), insert a thickness gage

between the rocker arm and the valve

bridge, and record the measured

valve clearance.

d) Measuring other cylinders

(d-1) 3JH4E

Turn the crankshaft 240

° and make

measurement and adjustment for the No.3

cylinder. Then adjust the No.2 cylinder.

The cylinder to be measured and adjusted

first does not have to be the No.1 cylinder.

Select and adjust the cylinder where the

piston is the nearest to the top dead center

after turning, and make measurement and

adjustment for other cylinders in the order of

ignition by turning the crankshaft 240

° each

time.

The measurement and adjustment method

of reducing the flywheel turning numbers

(for reference):

Set No.1 cylinder to the compression T.D.C.

and adjust the clearance of the

z mark of

the below table. Next, turn the flywheel

once (the suction/exhaust valve of No.1

cylinder is in the position of the overlap

T.D.C. at this time), and adjust the

clearance of the

{ mark.

Ignition order of 3 cylinder engines: 1

→ 3 →

2

Cylinder No. 1 2 3

Valve Suction Exhaust Suction Exhaust Suction Exhaust

No.1 compression T.D.C zzz zThe first time

No.1 overlap T.D.C {{ The second time

Valve

clearance

Rocker arm

Lock nut

Adjusting screw

010612-00E

2-valve head

Valve

clearance

Rocker arm

Valve bridge

010613-01E

4-valve head

Loading...

Loading...