2. Inspection and adjustment

65R1

(d-2) 4JH4E/ 4JH4-TE/ 4JH4-HTE

Turn the crankshaft 180

° and make

measurement and adjustment for the No.3

cylinder. Then adjust the No.4 and No.2

cylinders according to the order of injection.

The cylinder to be adjusted first does not

have to be the No.1 cylinder. Select and

adjust the cylinder where the piston is the

nearest to the top dead center after turning,

and make adjustment for other cylinders in

the order of ignition by turning the

crankshaft 180

° each time.

The measurement and adjustment method

of reducing the flywheel turning numbers

(for reference):

Set No.1 cylinder to the compression T.D.C.

and adjust the clearance of the

z mark of

the bottom table. Next, turn the flywheel

once, and adjust the clearance of the

{

mark.

Ignition order of 4 cylinder engines: 1

→ 3 →

4 → 2

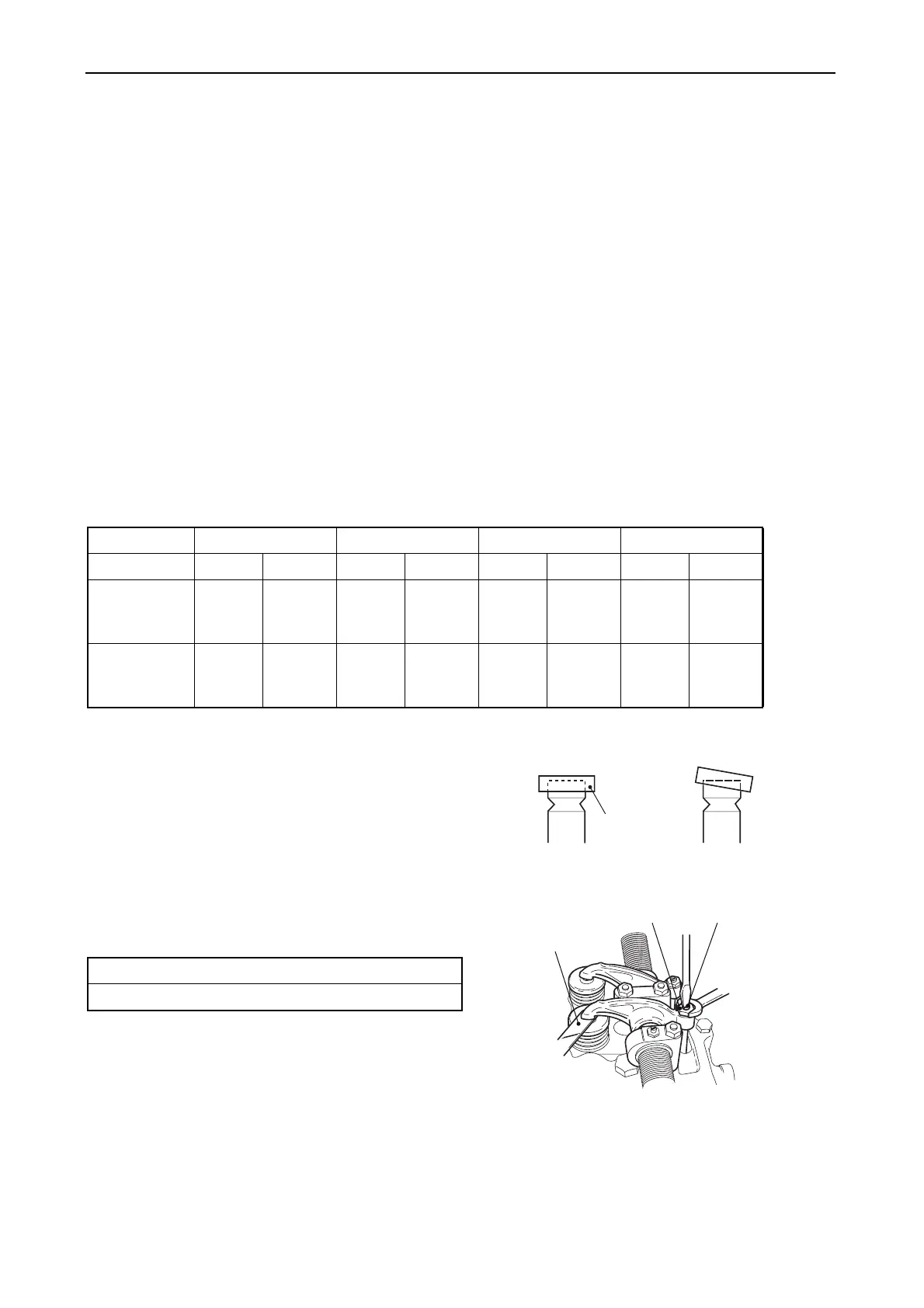

2) Valve clearance adjustment - 2 valves system

a) Loosen adjusting bolts

Loosen the lock nut and adjusting screw,

and check the valve for any inclination of

valve cap, entrance of dirt or wear.

b) Valve clearance adjustment

• Insert a 0.2 mm thickness feeler gauge

between the rocker arm and valve cap.

• Adjust the valve clearance by turning the

adjustment screw until there is a slight

“drag” on the feeler gauge when sliding it

between the rocker arm and the valve cap.

• Tighten the lock nut.

• Apply oil to the contact surface between

adjusting screw and push rod.

c) Adjusting other cylinders

See adjustment method for other cylinders

on page 64.

Cylinder No. 1 2 3 4

Valve Suction Exhaust Suction Exhaust Suction Exhaust Suction Exhaust

No.1

compression

T.D. C

zzz z

The first

time

No.4

compression

T.D. C

{{ {{

The

second

time

Standard intake/exhaust valve clearance (mm)

0.15-0.25

(Normal) (Abnormal)

Valve cap

010614-00E

011215-00E

Feeler gauge

Lock nut Adjusting screw

2 valve cylinder head

Loading...

Loading...