4.4

Checking Sample Program Operation

4-63

4

System Startup and Sample Programs

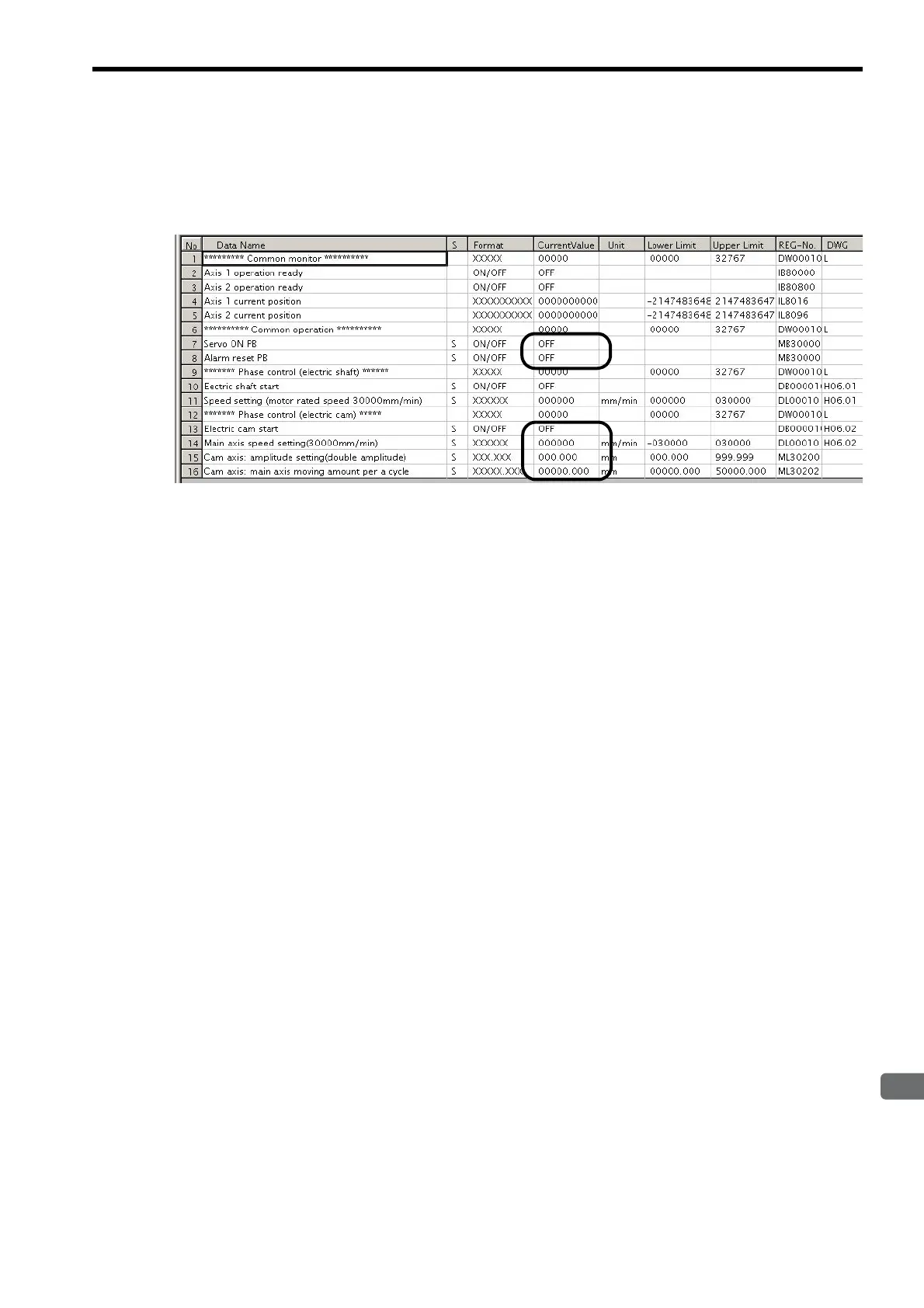

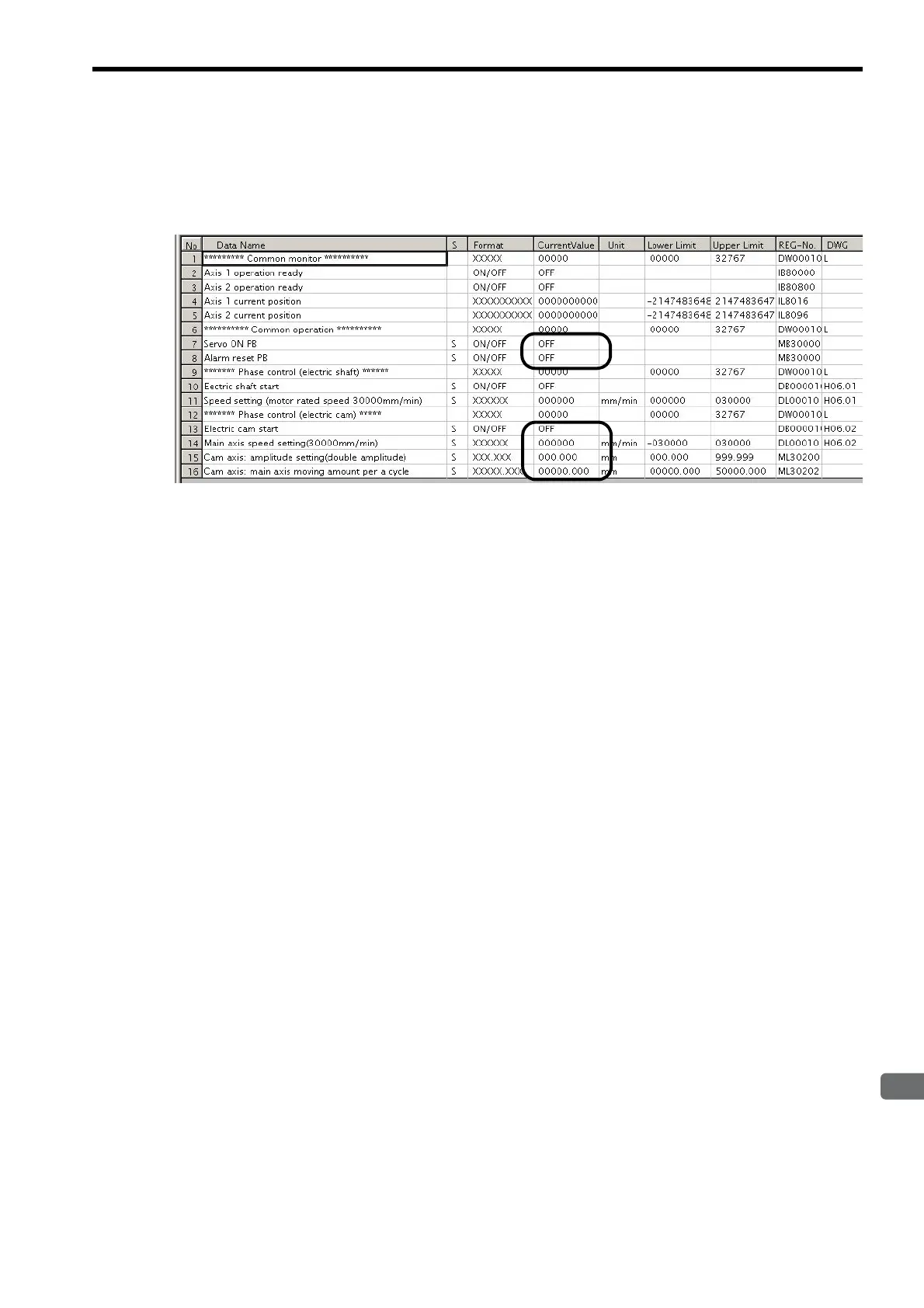

( 3 ) H06 Drawing Tuning Panel

Display the H06 Drawing Tuning Panel as shown in 4.4.1 How to Open the Tuning Panel Window on page 4-44.

Model system operation can be controlled by writing the current values for Common operation and Phase control

(electric shaft) from the Tuning Panel.

( 4 ) Procedure

1.

Servo ON

Change the Servo ON PB current value from OFF to ON.

The Servomotor will turn ON and the Servo will be clamped.

2.

Enter Cam Data

Enter any value within the setting range to Cam axis: amplitude setting (double amplitude) and Cam axis: main

axis moving amount per cycle. These settings create the cam pattern.

• Cam axis: amplitude setting (double amplitude), Setting range: 0 to 999.999

• Cam axis: main axis moving per cycle, Setting range: 0 to 50000.000

Cam pattern data is not changed when Electric cam start is set to ON.

3.

Start Electronic Cam Operation

Change the Electric cam start current value from OFF to ON.

Axis 2 will change to phase control (electric cam) mode. Enter OFF to exit phase control (electric cam) mode.

4.

Enter Main Axis Speed Settings

Enter any value within the setting range (

−

30000 to 30000) as the current value for Main axis speed setting.

This operation sets the master axis speed and starts operation.

Change the Electric cam start current value from ON to OFF when the check operation has been completed.

It is necessary to create routines within the actual application program in order to monitor and control the registers

corresponding to the signals and data listed in the table above.

The register numbers that correspond to the signals used in this sample program will be the register numbers

displayed under REG-No. next to DWG at the right of the Tuning Panel window.

Loading...

Loading...