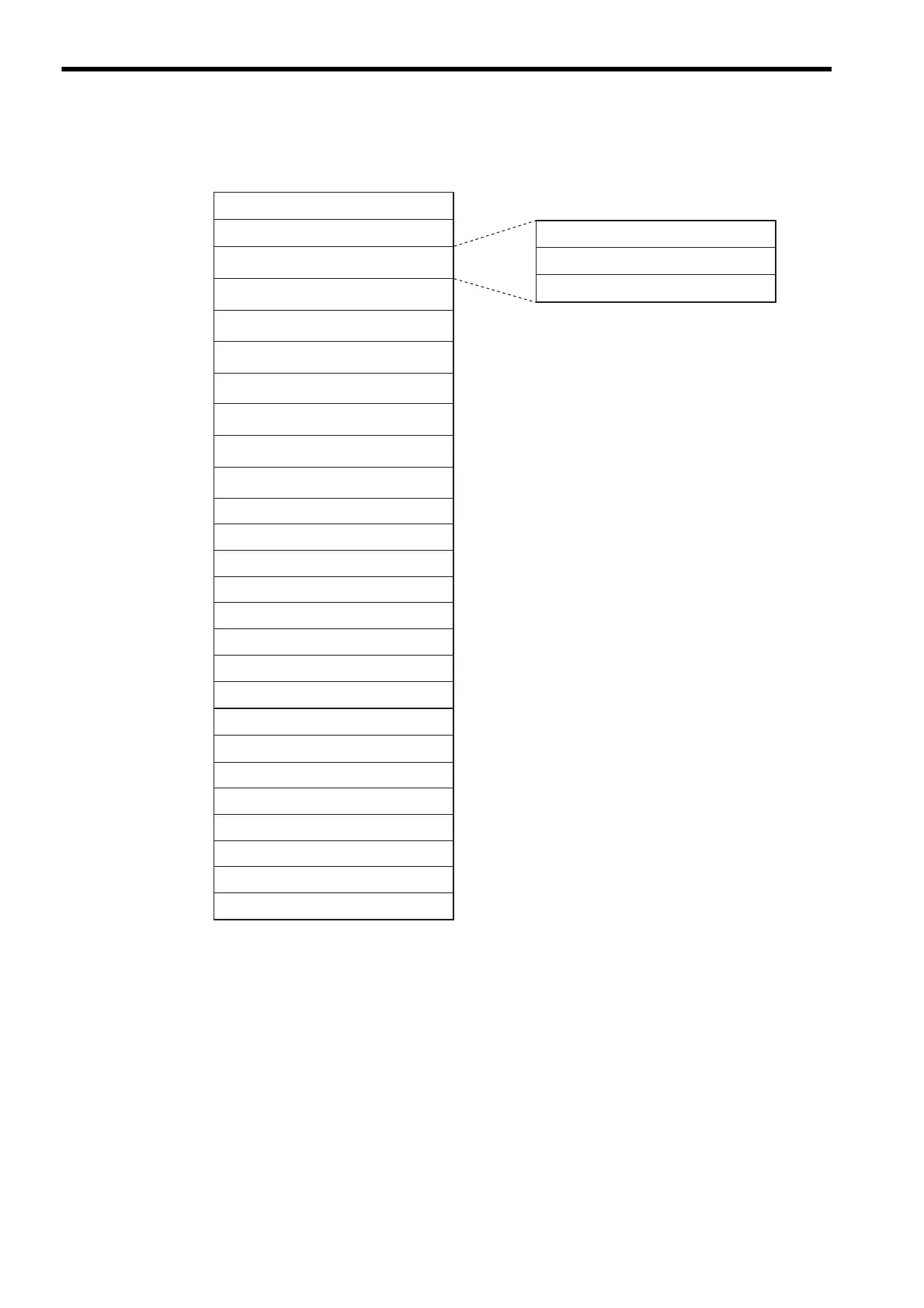

number setting).

+56

+54

+52

+50

+48

+46

+44

+42

+40

+38

+36

+34

+32

+30

+28

+0

+26

+23

+20

+17

+14

+11

+8

+5

+2

+1

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

2W

3W

3W

3W

3W

3W

3W

3W

3W

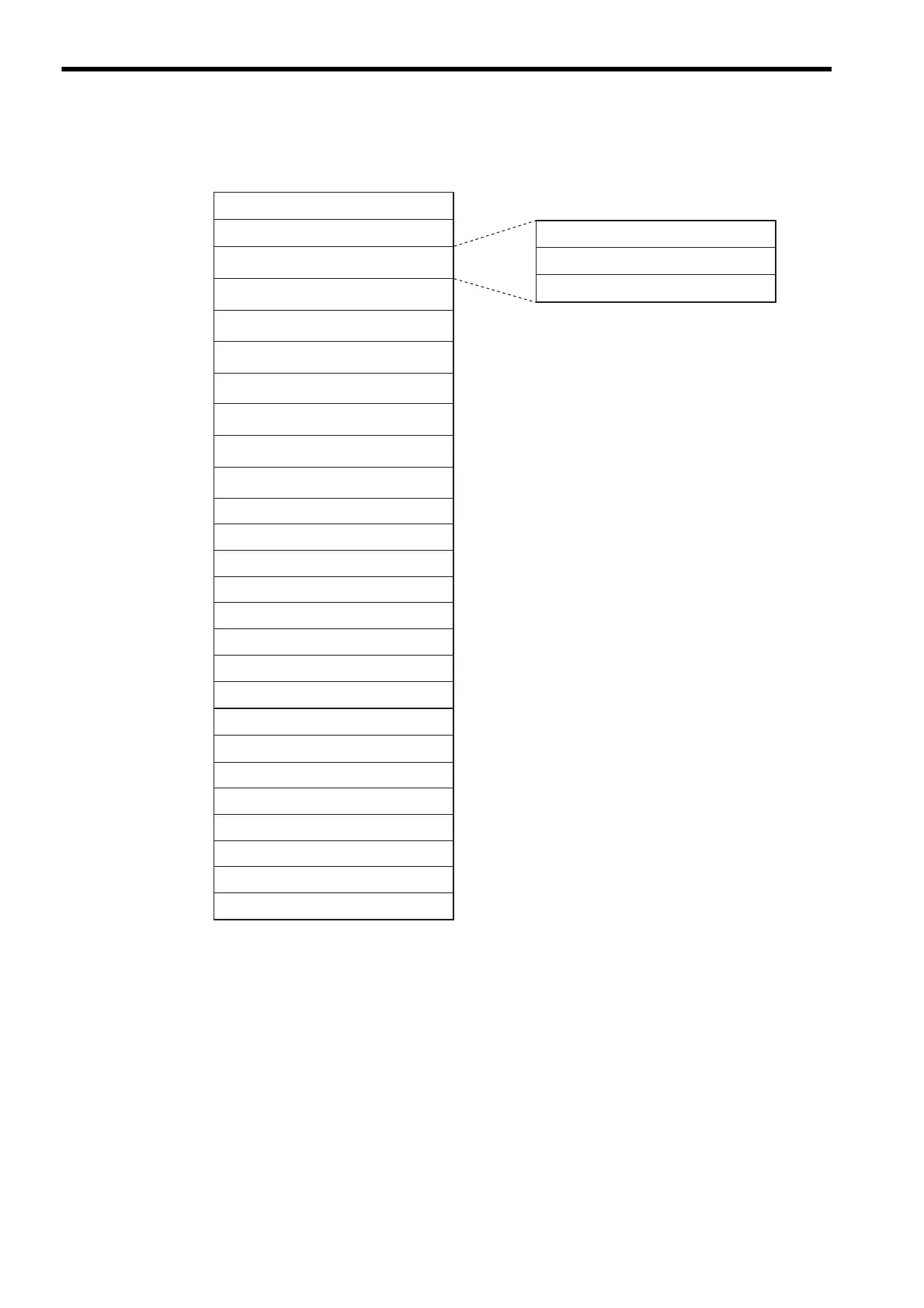

Program information used by work n

Program status

Program control signal

Parallel 0 information

Parallel 1 information

Parallel 2 information

Parallel 3 information

Parallel 4 information

Parallel 5 information

Parallel 6 information

Parallel 7 information

Executing program number

Executing block number

Error code

Logical axis #1 program current position

Logical axis #2 program current position

Logical axis #3 program current position

Logical axis #4 program current position

Logical axis #5 program current position

Logical axis #6 program current position

Logical axis #7 program current position

Logical axis #8 program current position

Logical axis #9 program current position

Logical axis #10 program current position

Logical axis #11 program current position

Logical axis #12 program current position

Logical axis #13 program current position

Logical axis #14 program current position

Logical axis #15 program current position

Logical axis #16 program current position

Loading...

Loading...