3.4 Setting Stop Mode

113

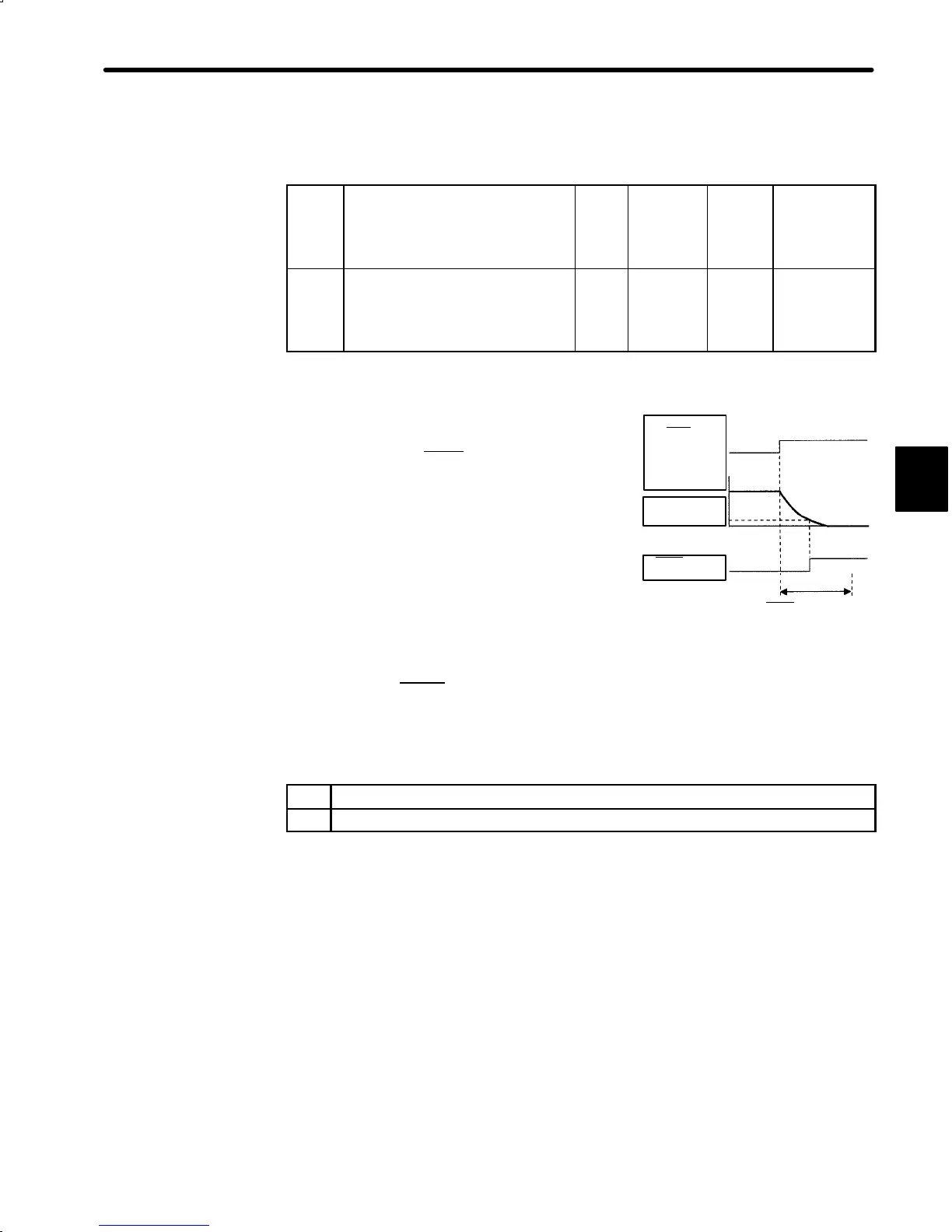

5) Set the following user constants to adjust brake ON timing so that holding brake is applied

when the motor stops.

Cn-15 BRKSPD

Speed Level at which

Brake Signal Is Output

during Motor Operation

Unit:

r/min

Setting

Range:

0to

Maximum

Speed

Factory

Setting:

100

For

Speed/Torque

Control and

Position

Control

Cn-16 BRKWAI

Output Timing of Brake

Signal during Motor

Operation

Unit:

10 ms

Setting

Range: 10

to 100

Factory

Setting:

50

For

Speed/Torque

Control and

Position

Control

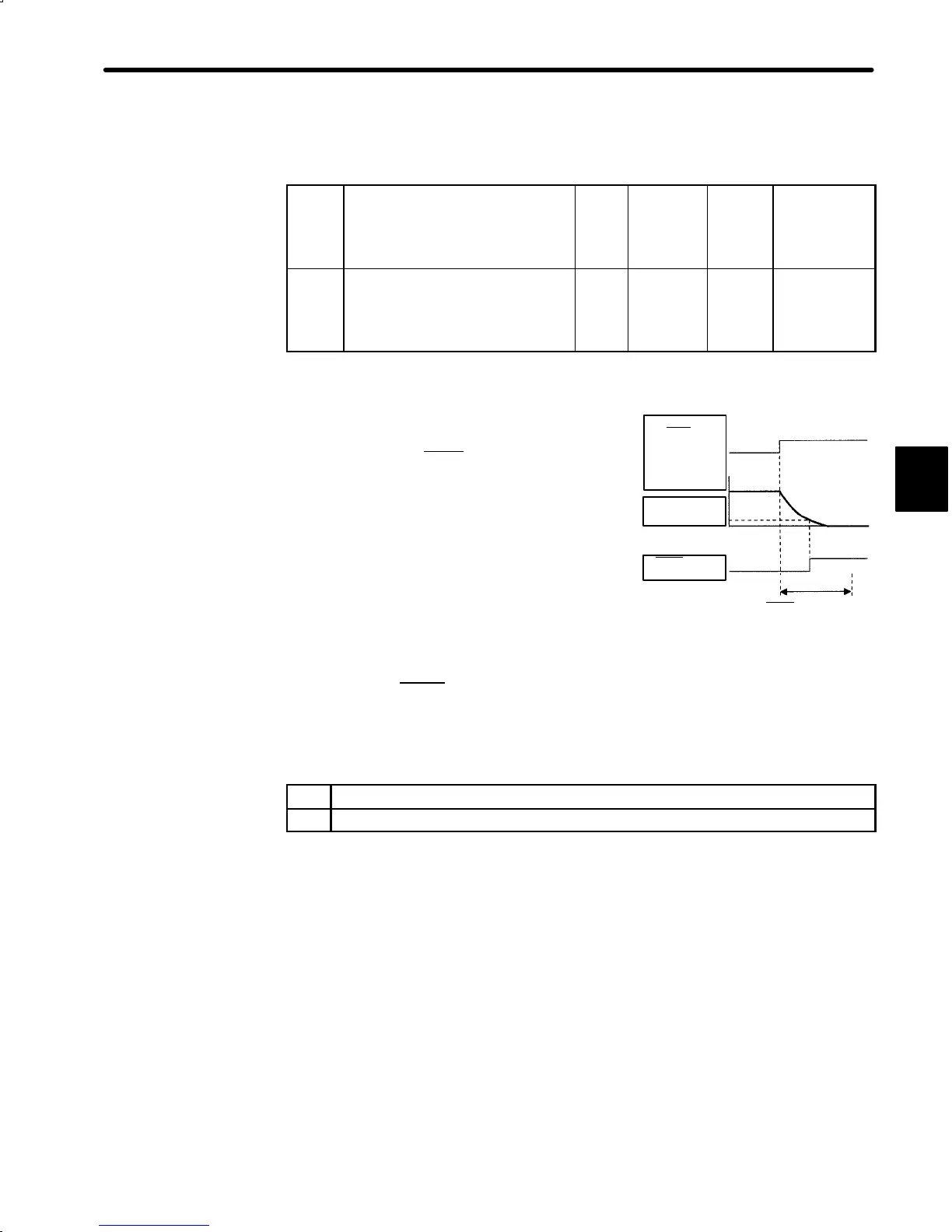

Cn-15 and Cn-16 are used for SGM/SGMP Ser-

vomotors with brake. Use these user constants to

set brake timing used when the servo is turned

OFF by input signal S-ON

(1CN-40) or alarm oc-

currence during motor rotation.

Since brakes for SGM/SGMP Servomotors are

designed as holding brakes, if brake is applied at

motor running, brake generates excessive fric-

tion. Therefore, brake ON timing when the motor

stops must be appropriate. Adjust the user

constant settings while observing machine opera-

tion.

•

Conditions for TGON

+ signal (1CN-27) output

during motor operation. The circuit between

1CN-27 and 1CN-28 is opened in either of the

following situations.

1 Motor speed drops below the value set in Cn-15 (BRKSPD) after servo OFF occurs.

2 The time set in Cn-16 (BRKWAI) has elapsed since servo OFF occurred.

3

Brake Timing when Motor is in Stopped Status

Power OFF

by S-ON

input

(1CN-40) or

alarm

occurrence

and main

power OFF

Servo ON

Servo OFF

Motor speed

(r/min)

Stop by dynamic

brake or coasting

to a stop (Cn-01

bit 6)

BRKSPD

(Cn-15)

TGON

+ output

(1CN-27)

Release

brake

Apply brake

BRKW AI

(Cn-16)

When this time elapses, TGON+ signal is

output.

Loading...

Loading...