MEASURES TO SATISFY THE REQUIREMENTS OF EMC DIRECTIVE

7.2.2 Applicable Noise Filter

418

7.2 Measures to Satisfy the Requirements of EMC Directive

This section describes the required measures to adapt DR2 Servopack to EMC directive

(EN50081−2, EN50082−2).

7.2.1 Applicable Servomotor 418...........................................

7.2.2 Applicable Noise Filter 418............................................

7.2.3 Motor Cables 419...................................................

7.2.4 Encoder Cables 419.................................................

7.2.5 Control I/O 420......................................................

7.2.6 Digital Operator and Monitoring by Personal Computer 420................

7.2.7 The Core on the Cable 421...........................................

7.2.8 Wiring 421..........................................................

7.2.1 Applicable Servomotor

1) Use Yaskawa Servomotor conforming to EN standard.

For details, refer to 5.4.2 Servomotor Dimensional Drawings (TÜV approved).

Servomotor Type Example: SGM−01V312 (200VAC, 100W)

SGM−01W312 (100VAC, 100W)

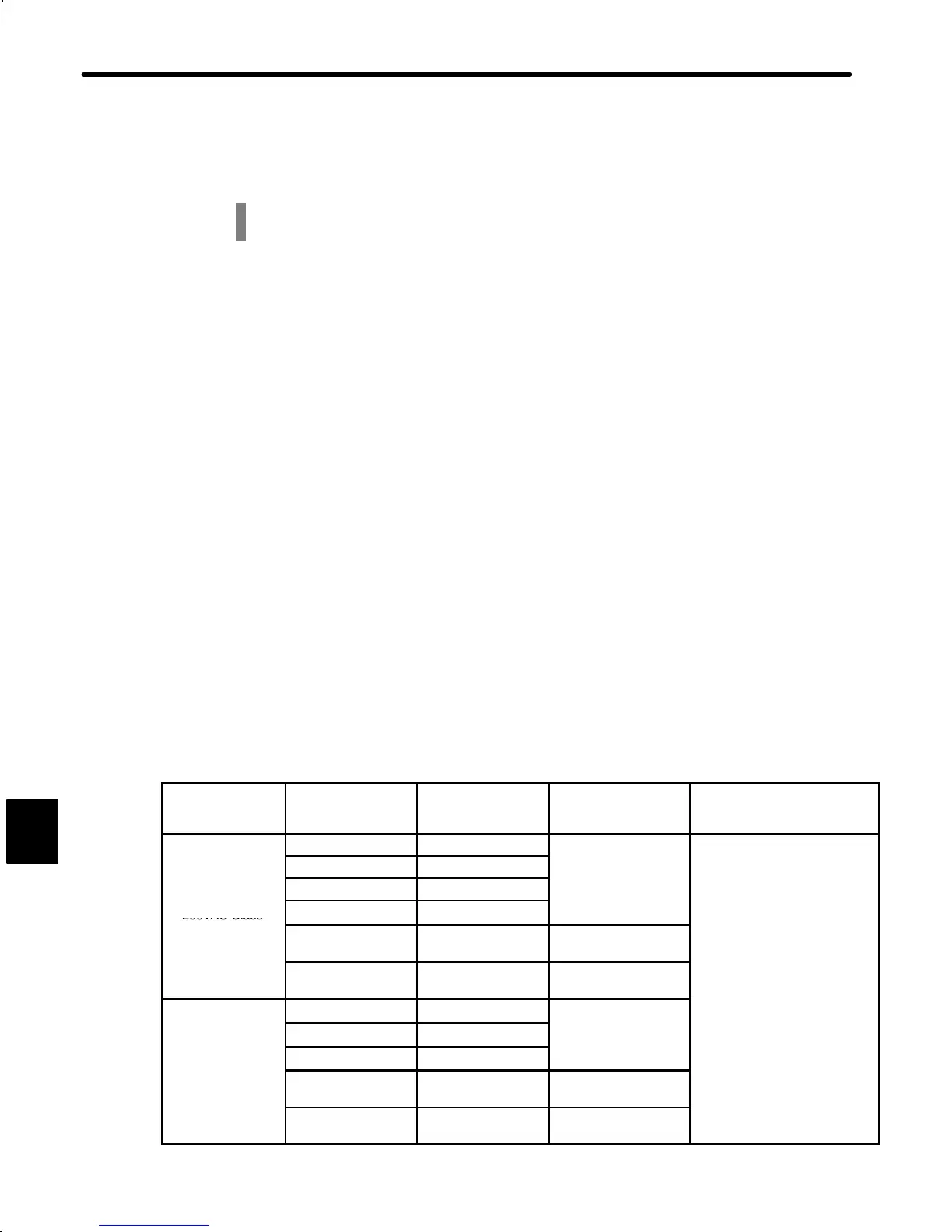

7.2.2 Applicable Noise Filter

1) Use the following noise filter.

Make sure to ground the noise filter securely.

Applied Voltage

Servopack Type

DR2−

Servopack Rated

Input Current

A (rms)

Noise Filter Type

and Specifications

(Input Line)

Noise Filter Type and

Specifications

(Power Supply for Brake)

A3Aj 1.3

A5Aj 1.5

SUP−P5H−EPR

01Aj 2.5

250V, 5A

200VAC Class

02Aj

4.0

04Aj

6.0

SUP−P8H−EPR

250V, 8A

08Aj

11.0

SUP−P10H−EPR

250V, 10A

SUP−P5H−EPR

A3Bj

2.0

,

A5Bj

2.6

SUP−P5H−EPR

250V, 5A

01Bj

4.5

,

100VAC Class

02Bj

8.0

SUP−P8H−EPR

250V, 8A

03Bj

14.0

SUP−P10H−EPR

250V, 10A

7

Loading...

Loading...