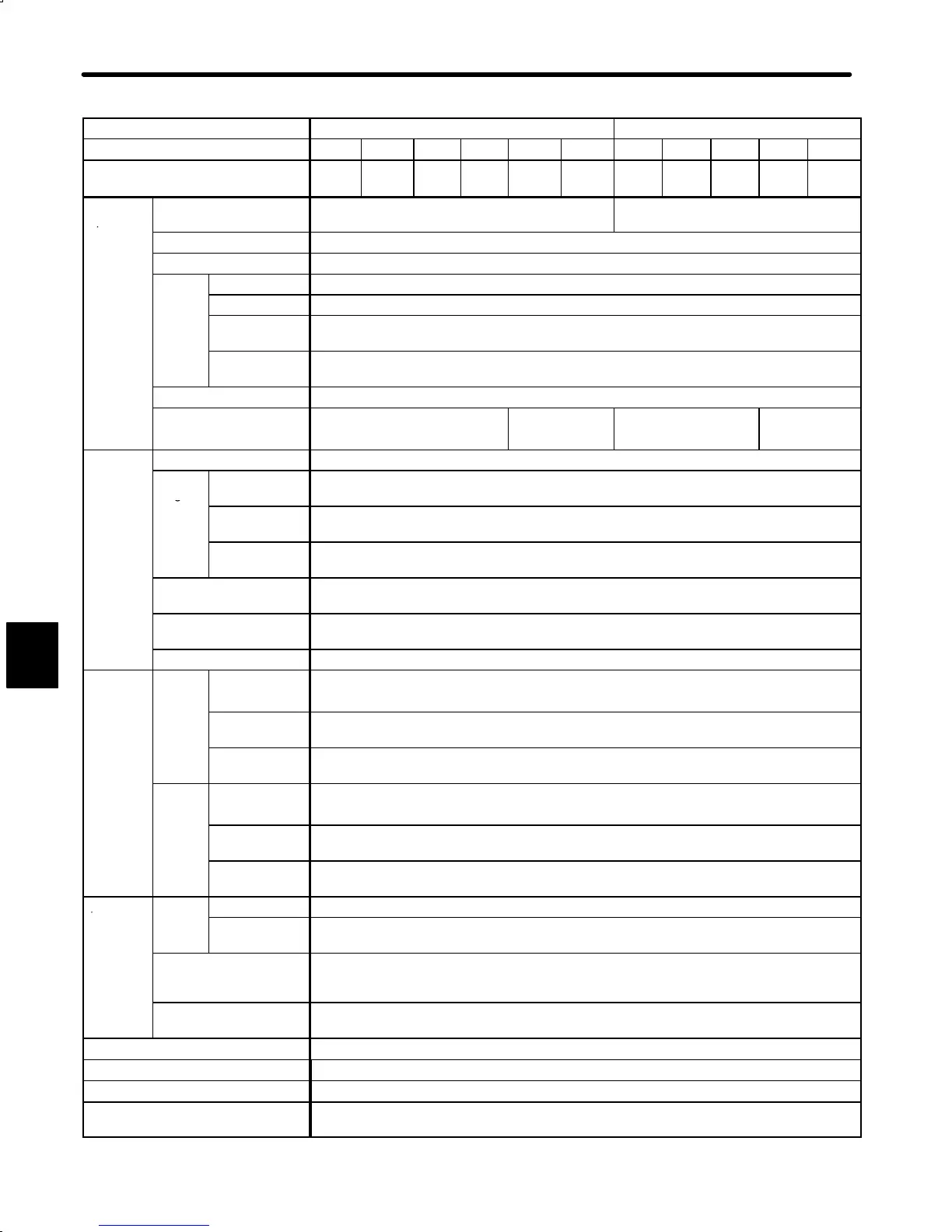

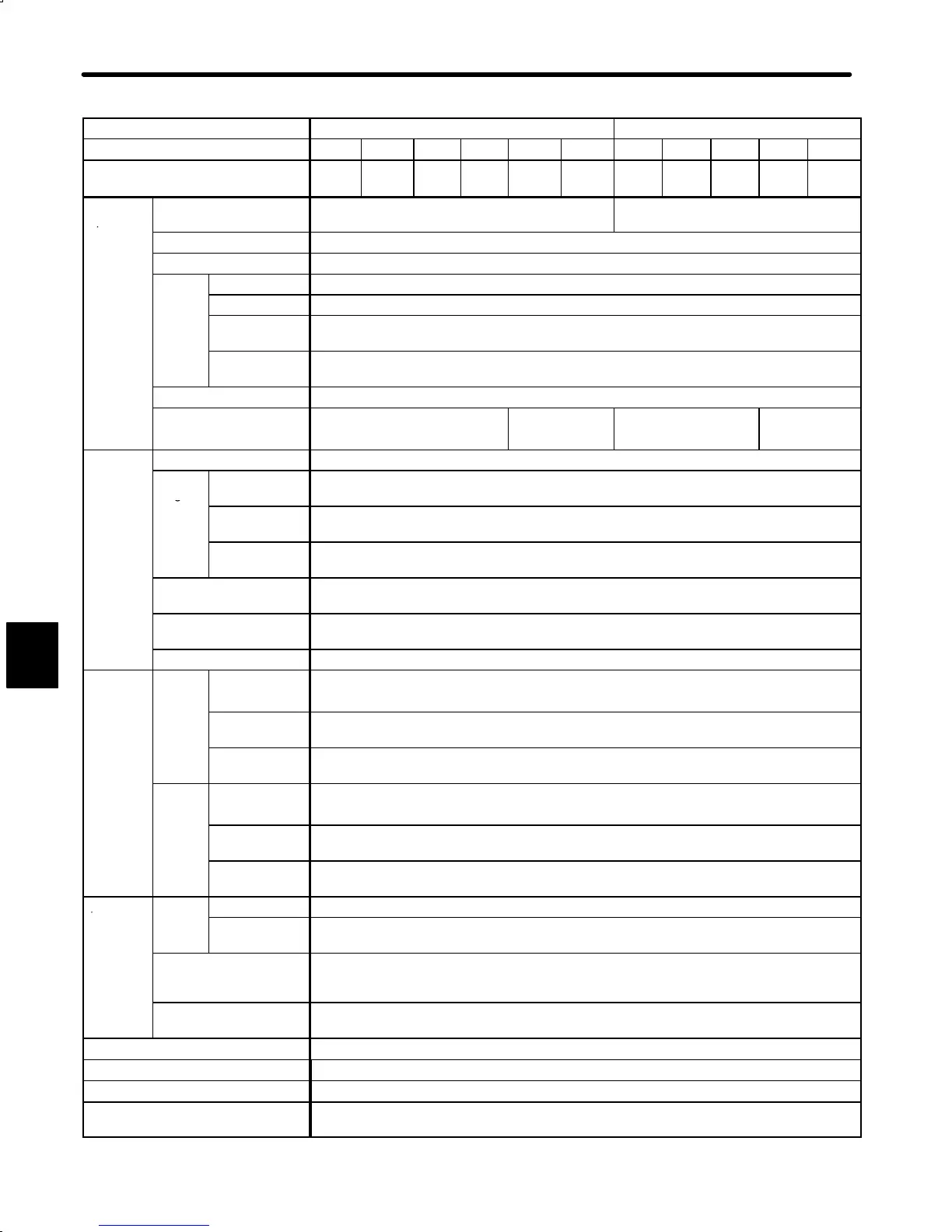

SERVO SELECTION AND DATA SHEETS

5.3.1 Ratings and Specifications cont.

234

Voltage 200 VAC 100 VAC

Servopack Type DR2- A3AC A5AC 01AC 02AC 04AC 08AC A3BC A5BC 01BC 02BC 03BC

Max. Applicable Motor Capacity

W (HP)

30

(0.04)

50

(0.07)

100

(0.13)

200

(0.27)

400

(0.53)

750

(1.01)

30

(0.04)

50

(0.07)

100

(0.13)

200

(0.27)

300

(0.40)

Basic

Specifica-

Power Supply

(Main/control circuit)

Single-phase 200 to 230 VAC+10% to −15%,

50/60Hz

Single-phase 100 to 115 VAC+10% to

−15%*

2

, 50/60Hz

tions

Control Method Single-phase, full-wave rectification IGBT-PWM (sine-wave driven)

Feedback Incremental encoder 2048 P/R, absolute encoder 1024 P/R

Loca-

Ambient Temp.

0 to +55°C*

3

tion

Storage Temp.

−20 to +85°C

Ambient/Stor-

age Humidity

90% or less (non-condensing)

Vibration/Shock

Resistance

0.5/2G

Structure Rack-mounted*

7

Approx. Mass kg (lb) 2.5 (5.51) 3.7 (8.16) 2.5 (5.51) 3.7 (8.16)

Perfor-

Speed Control Range*

4

1:5000

mance

Speed

Regu-

Load

Regulation

0% to 100%:0.01% max. (at rated speed)

lation*

5

Voltage

Regulation

+10% to -15%: 0.01% max. (at rated speed)

Temperature

Regulation

25¦25°C: ¦0.2% max. (at rated speed)

Frequency

Characteristics

250 Hz (at J

L

=J

M

)

Torque Control

(Repeatability)

¦2.0%

Accel/Decel Time Setting 0to10s

Input

Signal

Speed

Refer-

Rated Refer-

ence Voltage

¦6 VDC (positive motor rotation with positive reference) at rated speed (factory setting)

Variable setting range: ¦2to¦10 VDC at rated torque

Input

Impedance

Approx. 30kΩ

Circuit Time

Constant

Approx. 330µs

Torque

Refer-

Rated Refer-

ence Voltage

¦3 VDC (positive motor rotation with positive reference) at rated speed (factory setting)

Variable setting range: ¦1to¦10 VDC at rated torque

Input

Impedance

Approx. 30kΩ

Circuit Time

Constant

Approx. 330µs

I/O

Posi-

Output Form A-, B-, C-phase line driver*

8

Signals tion

Output

Frequency

Dividing Ratio

(16 to N) /N (N=2048, 1024)*

6

Sequence Input Servo ON, P drive (or motor forward/reverse by torque control, zero-clamp drive reference, or

internal setting speed), forward run stop (P-OT), reverse run stop (N-OT), current limit + selection

(or internal speed selection), current limit − selection (or internal speed selection), alarm reset

Sequence Output Torque limit detection (or speed coincidence) , motor running output (or external brake interlock),

servo ready, servo alarm, 3-bit alarm codes

Dynamic Brake Operated at main power OFF, servo alarm or overtravel.

External Regenerative Unit Required when exceeding the allowable load inertia*

1

Overtravel Dynamic brake stop at P-OT or N-OT or deceleration stop

Protective Functions Overcurrent, overload, overvoltage, overspeed, reference input read error, overrun prevention,

origin error, CPU error, encoder error, fuse blown

5

Loading...

Loading...