7.11 Manual Offset-Signal Adjustment of the Motor Current

Detection (Fn00F)

Use this function only if the torque ripple is still high after the automatic offset adjustment of the motor cur-

rent detection signal (Fn00E).

Follow the steps below.

If this function is executed carelessly, it may worsen the characteristics.

Observe the following precautions when performing manual servo tuning.

• Run the servomotor at a speed of approximately 100 min

-1

.

• Adjust the offset until the torque reference monitor ripple is minimized, monitoring the

torque reference by using the analog monitor.

• Adjust the phase-U and phase-V offsets alternately several times until these offsets

are well balanced.

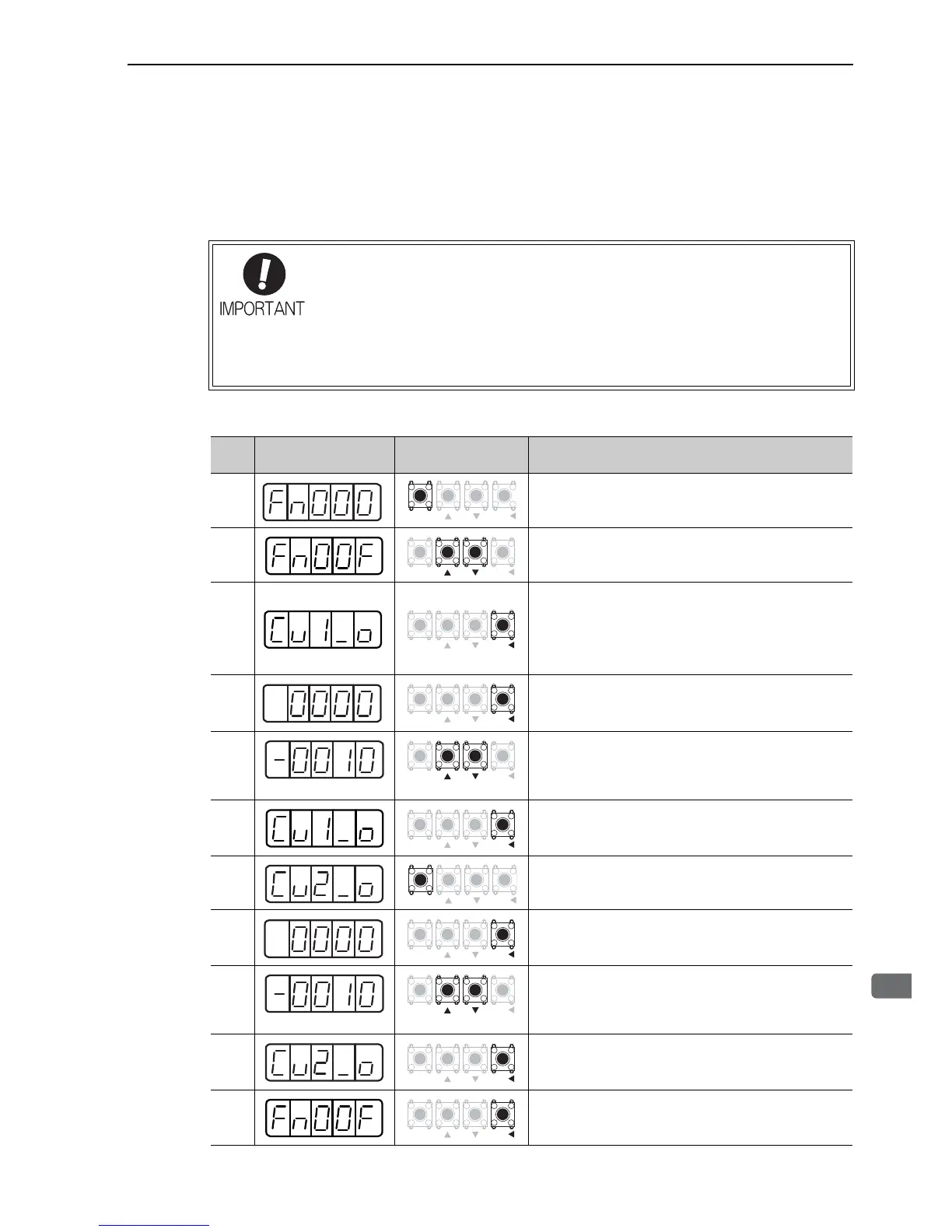

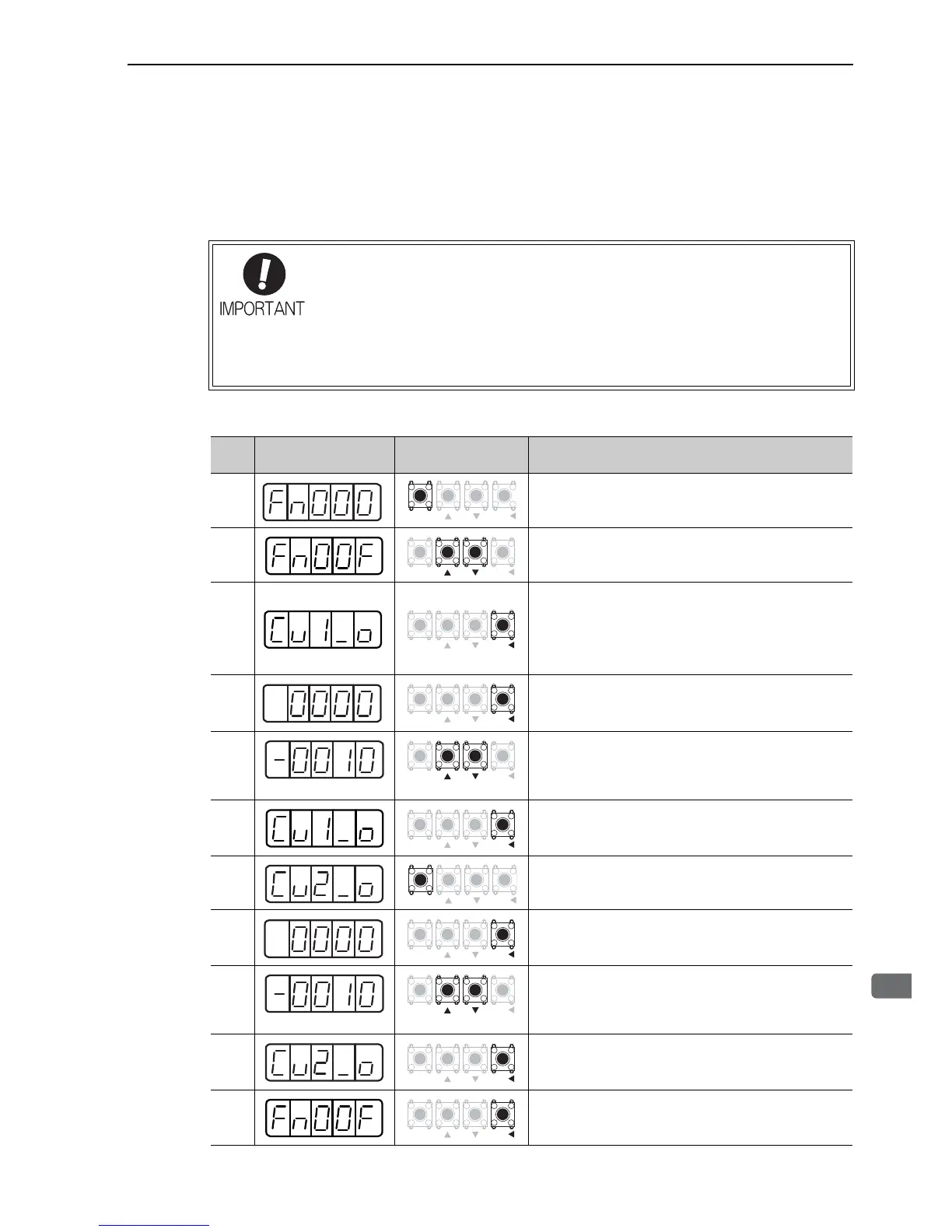

Step

Display after

Operation

Keys Operation

1

Press the MODE/SET Key to select the utility function

mode.

2 Press the UP or DOWN Key to select Fn00F.

3

Press the DATA/SHIFT Key for approximately one second.

The display shown on the left (phase U) appears.

Note: When "no-oP" blinks for approximately one second,

the write prohibited setting is set in Fn010. Change

the setting in Fn010, and press the key again after

enabling writing. (Refer to 7.12.)

4

Press the DATA/SHIFT Key to display the phase-U offset

amount.

5

Press the UP or DOWN Key to adjust the offset. Carefully

adjust the offset while monitoring the torque reference mon-

itor signal.

Adjustable range: −512 to

+511

6

Press the DATA/SHIFT Key.

The display shown on the left appears.

7

Press the MODE/SET Key.

The display shown on the left appears (phase V).

8

Press the DATA/SHIFT Key to display the phase-V offset

amount.

9

Press the UP or DOWN Key to adjust the offset. Carefully

adjust the offset while monitoring the torque reference mon-

itor signal.

Adjustable range: −512 to

+511

10

Press the DATA/SHIFT Key.

The display shown on the left appears.

11

When the offset adjustment completes, press the DATA/

SHIFT Key for approximately one second.

"Fn00F" is displayed again.

Loading...

Loading...