3D Systems, Inc.

20

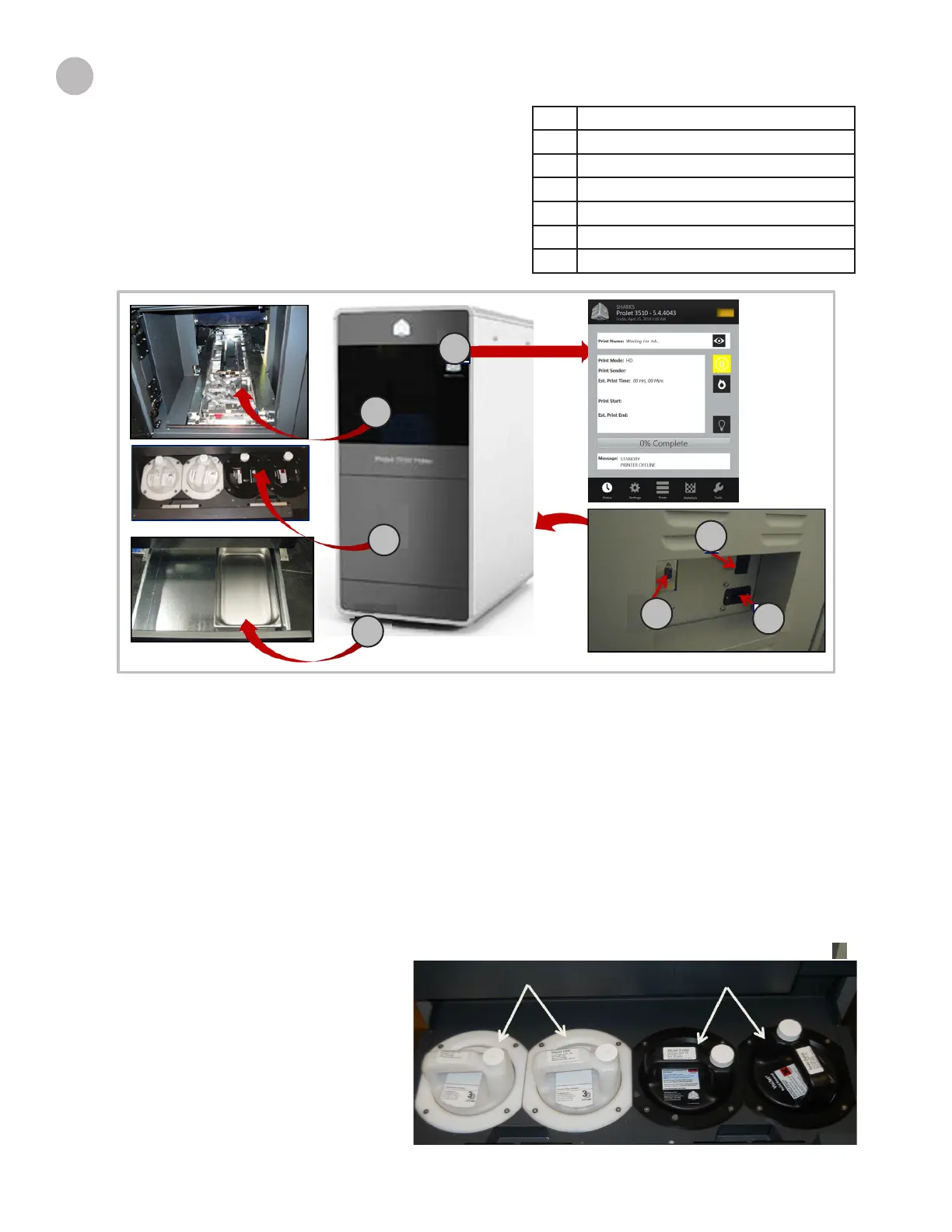

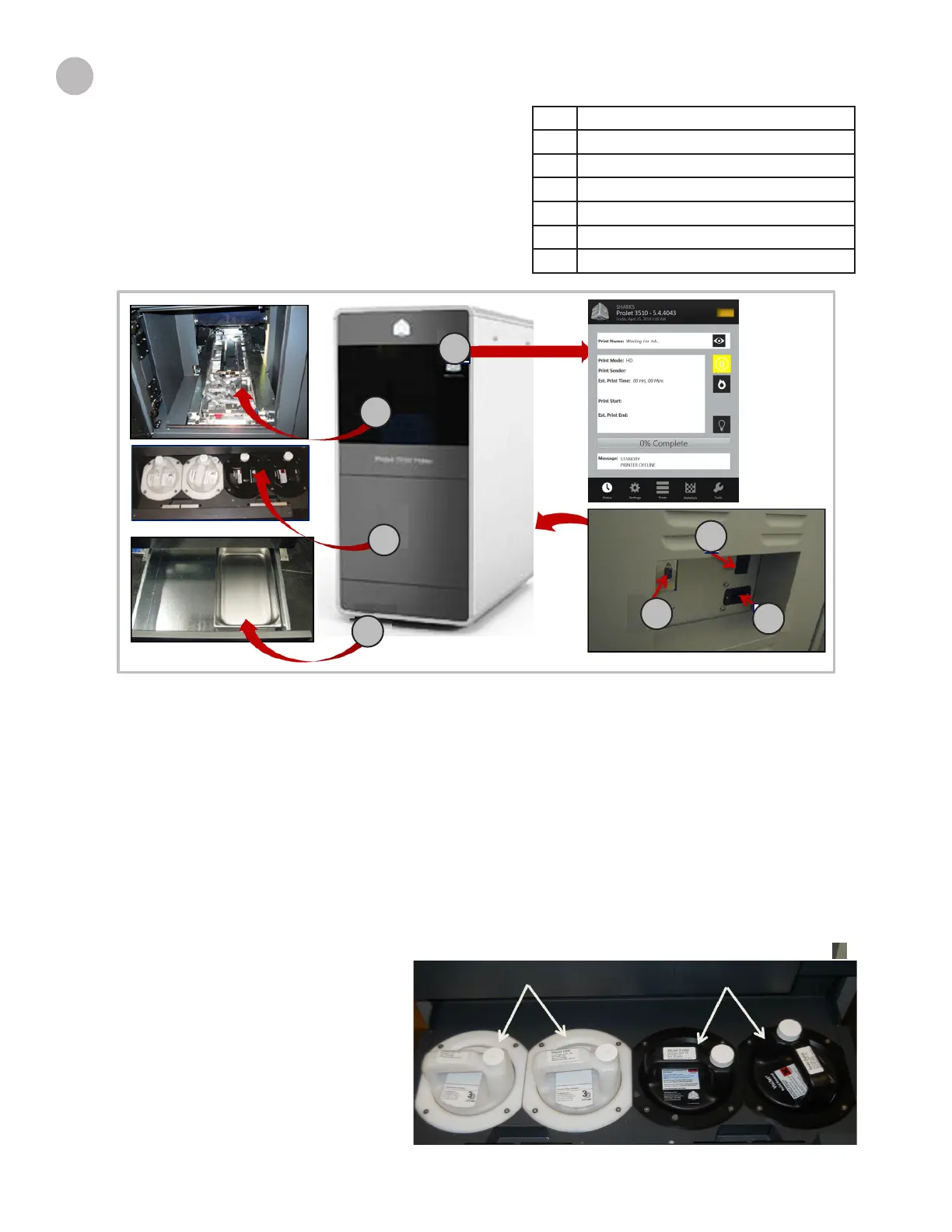

FAMILIARIZATION

3-D printing systems are Multi-Jet-Modeling (MJM) line of printers.

The solid imaging printers produce plastic prototype parts from 3D

solid Computer-Aided Design (CAD) models and through the printer

client software. The parts are generated in a rapid prototyping (RP)

environment. The primary features of the 3-D printer are the user

interface, build chamber, material delivery module, and the waste

material drawer. The back of the printer houses the power switch,

internet and the power cord connections.

A Build Chamber

B Support & Parts Material Module

C Waste Drawer

D Operator’s Touchscreen Panel

E1 USB Connection

E2 Power Switch

E3 Printer Power Outlet

The part material used to build the parts is an ultraviolet (UV) curable material. After a layer of material is deposited in the

build chamber, the part is exposed to a UV ash lamp. The UV energy is absorbed by the material converting a liquid part

material to a solid polymer. When the build is complete the part (consisting of the two materials) is adhered to the build

platform by means of the support material.

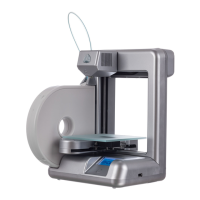

The material delivery module consist of four material cartridge holders; the two left side holders are for the support material

(white) cartridges. The right side of the module are for two part material (black) cartridges. Once materials are heated, they

are feed to the printhead. Material waste is generated by two processes; cleaning the printhead array plate and planariza-

tion. The cleaning process involves purging jets and wiping the printhead array plate. Gravity pulls the waste material from

the Head Maintenance Station (HMS) trough into the waste umbilical. The combined waste material is then purged. The

printhead cleaning process is invoked automatically prior to test build and parts build.

The three dimensional solid parts built by the printer consist of two materials (support material and part material). The

support material is a wax based material providing adhesion to build platform, as well as, providing material used to

produce supports required to build the model.

After the build is complete, the platform and the

part is then removed from the printer. A secondary

operation, known as nishing, is required to

provide a nished/cleaned part. Refer to your

ProJet® Finisher’s Guide for more information on

part processing and nishing.

Support Material Part Material

13

A

B

C

D

E1

E2

E3

Loading...

Loading...