3D Systems, Inc.

55

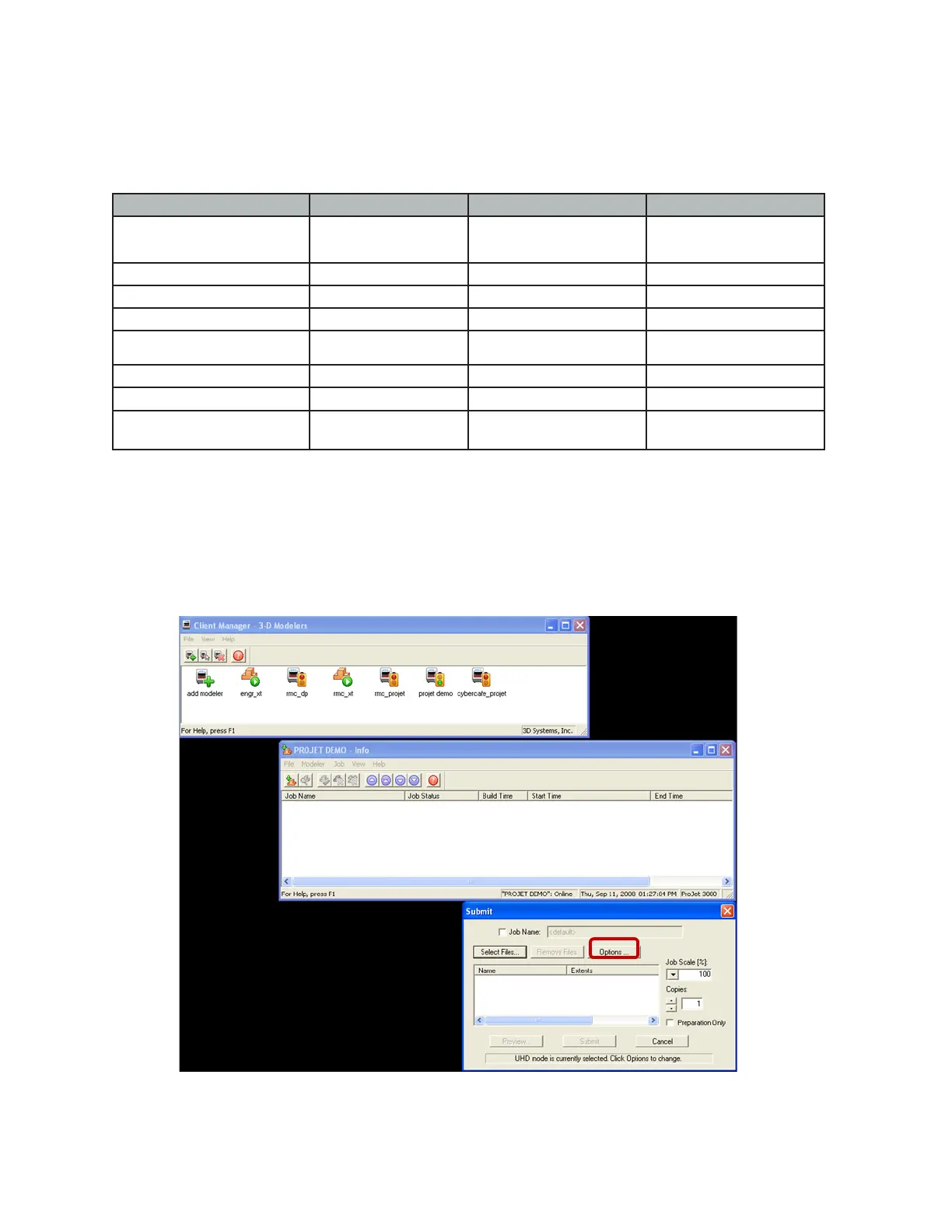

SHRINK COMPENSATION FOR PROJET VISIJET® MATERIALS

• Material shrinkage occurs in thermosets as they transition from liquid state to solid state during the curing process.

• The ProJet Accelerator Client Software has features that allow the user to compensate for the natural shrinkage of the material in

order to ne tune the accuracy of a part.

• These shrink compensation values serve as general guidelines to setting shrink compensation. Part building and cleaning in a

controlled process will best determine the optimal shrink compensation values for a particular geometry.

Enter Standard Shrink Compensation Values for the material.

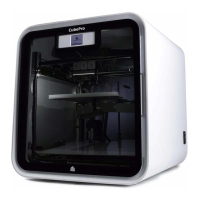

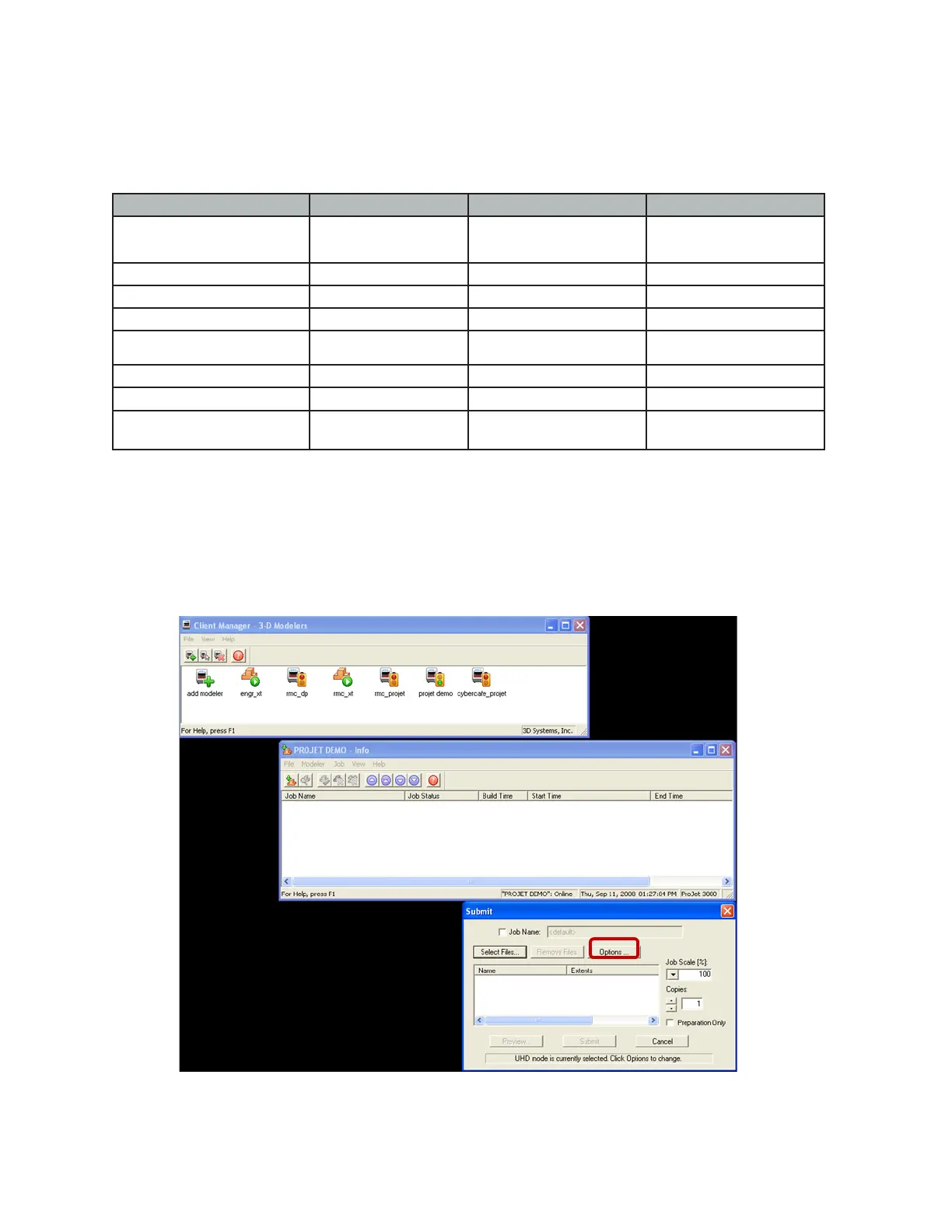

• Open ProJet Accelerator Client software and select the desired printer.

• Select the part to build.

• Select the “Options” button.

Material X value Y value Z value

SR200/Proplast, Techplast,

Navy

1.01% 1.01% 0.00%

HR200/Procast 1.01% 1.01% 0.00%

EX200/Crystal 0.55% 0.25% 0.00%

MX 0.40% 0.60% 0.00%

DP200/Dencast 0.50% 0.50% 1.00%

MP200/Stoneplast 0.48% 0.39% 0.00%

Pearlstone 0.8% 1.0% 0.00%

CP200&CPX200/Prowax/

Hi-Cast

0.40% 0.40% 0.00%

Loading...

Loading...