3D Systems, Inc.

64

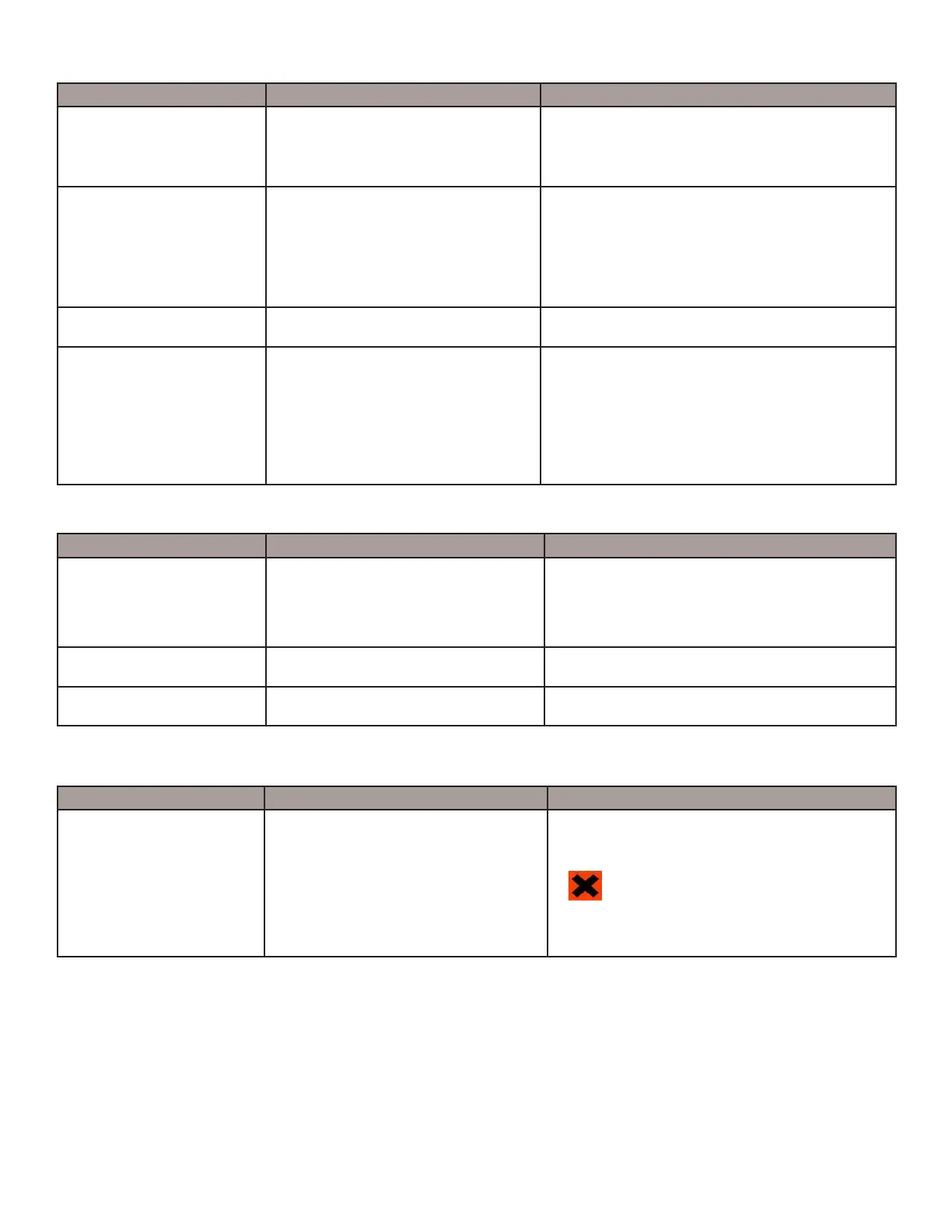

MATERIAL QUALITY GUARANTEE ERROR MESSAGES

MOTION SYSTEM ERROR MESSAGES

MESSAGE CAUSE ACTION

RT_ERROR: AirPurge 1 (or 2)

Not Support (or build) material

cartridges not detected

• Printer is out of material cartridge. Add the specied material cartridge, install a clean

build platform and repeat the build job.

If error message occurs again, contact your Technical

Support Hotline.

Support (or build) material

cartridge not melted

• A cold cartridge was added to the and

it did not have enough time to melt

before the printer requested material.

The build will abort if it needs to use the questionable

cartridge to nish the build.

Install a clean build platform and repeat the build job

after the printer has reached build temperature.

If error message occurs again, contact your Technical

Support Hotline.

Support (or build) material

cartridge expired

• The material identication system

detected expired material.

Follow the discard instructions posted on the touch

screen.

Support (or build) material

cartridge incorrect type

• A material cartridge was inserted into

the wrong holder.

The build will abort if it needs to use the questionable

cartridge to nish the build.

Follow the discard instructions posted on the touch

screen.

If error message occurs again and you have inserted

the correct material cartridge into the correct holder in

drawer, contact your Technical Support Hotline.

MESSAGE CAUSE ACTION

X-Following ERROR • An attempt to open the build chamber

door was made, or position sensor

errors occurred

Ensure the build chamber door is secured, then cycle

power to the printer. If error message occurs again,

contact your Technical Support Hotline.

Negative Firing Delay • Variations in scanning axis velocity. Cycle power to the printer. If error message occurs

again, contact your Technical Support Hotline.

SPause Timeout ERROR • Position sensor contamination. Cycle power to the printer. If error message occurs

again, contact your Technical Support Hotline.

MESSAGE CAUSE ACTION

RT_ERROR: UV Lamp Power

Too Low

• UV sensor detected a possible fault

Variations in scanning axis velocity.

Cycle power to the printer. If error message occurs

again, contact your Technical Support Hotline.

CAUTION: To prevent skin exposure to

uncured part material, do not handle

parts in a build without wearing gloves if

a UV lamp problem occurred during the

build.

UV SUBSYSTEM ERROR MESSAGE

Loading...

Loading...