3D Systems, Inc.

54

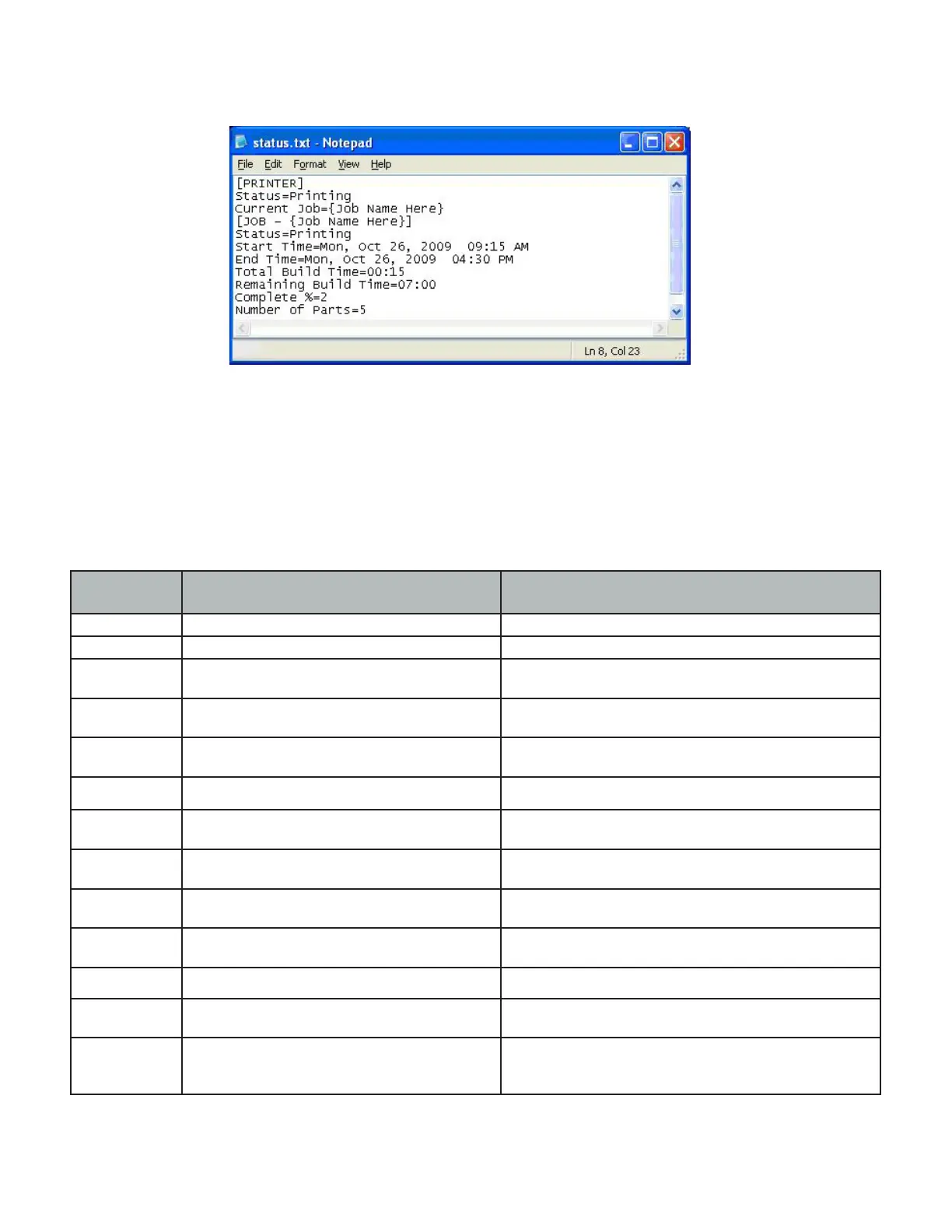

Output Report

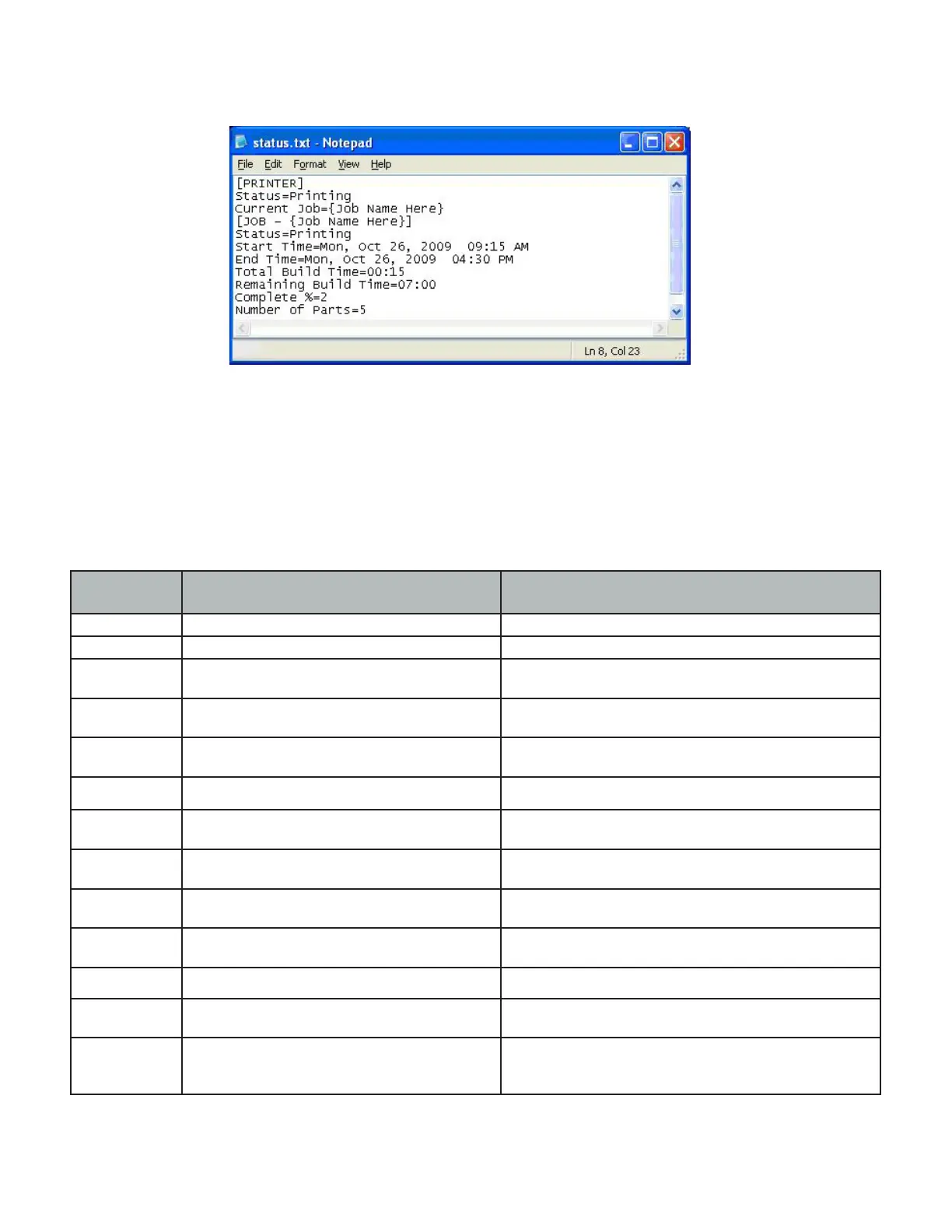

• After a successful run of the modelerbatch, the application will output a report (ReportFile or IniFile) to the location designated

in the command script. See example below.

• If building in UHD Mode, “Number of Parts” includes the Verication Strip in the part total.

• After a machine is put “Online”, there is a period of time that a job takes to initialize. During that time, the Status returned will

be “Not Printing” and the End Time, Total Build Time and Remaining Build Time will all report “Not Estimated”. Once the state

changes to “Printing”, these values will be reported accurately.

Exit Error Codes

• The Printer Batch Processing applications including ModelerBatch.exe and ModelerStatus.exe will return exit error codes if

there are any issues while the application is running. The following table gives a description of each possible error code that

may be reported while running either application.

Exit Error

Code

Error Description Description

0 No Error

500 The iniFile is not specied for batch processing Specify the parameter IniFile as the argument

501 The specied iniFile does not exist or cannot be

opened

Please make sure the IniFile exist

502 IP Address eld not present Add the IP address

503 IP address cannot be validated Check the IP address

504 Number of Parts eld does not present The number of parts must be specied and larger than 0

505 STL le for Part# can not be found Missing the STL le. Make sure it exists and accessible

506 Communication error. Unknown printer type or

printer not connected.

Please check IP address. .

507 Verication Strip le cannot be found. Reinstall the client or restore the verication strip les.

508 Wait time-out. Please verify the network and increase the wait timeout in

the IniFile.

509 Cannot connect to the printer. Please check IP address.

510 Part outside platform or exceed platform size Check the size and position of all parts to ensure that they

will t inside the platform

511 Too much part data for Auto Part Placement or

Quick Build Placement

Please not use Auto Part Placement or Quick Build.

For example, use Print Preview and manually position the

geometries.

Loading...

Loading...