3D Systems, Inc.

9

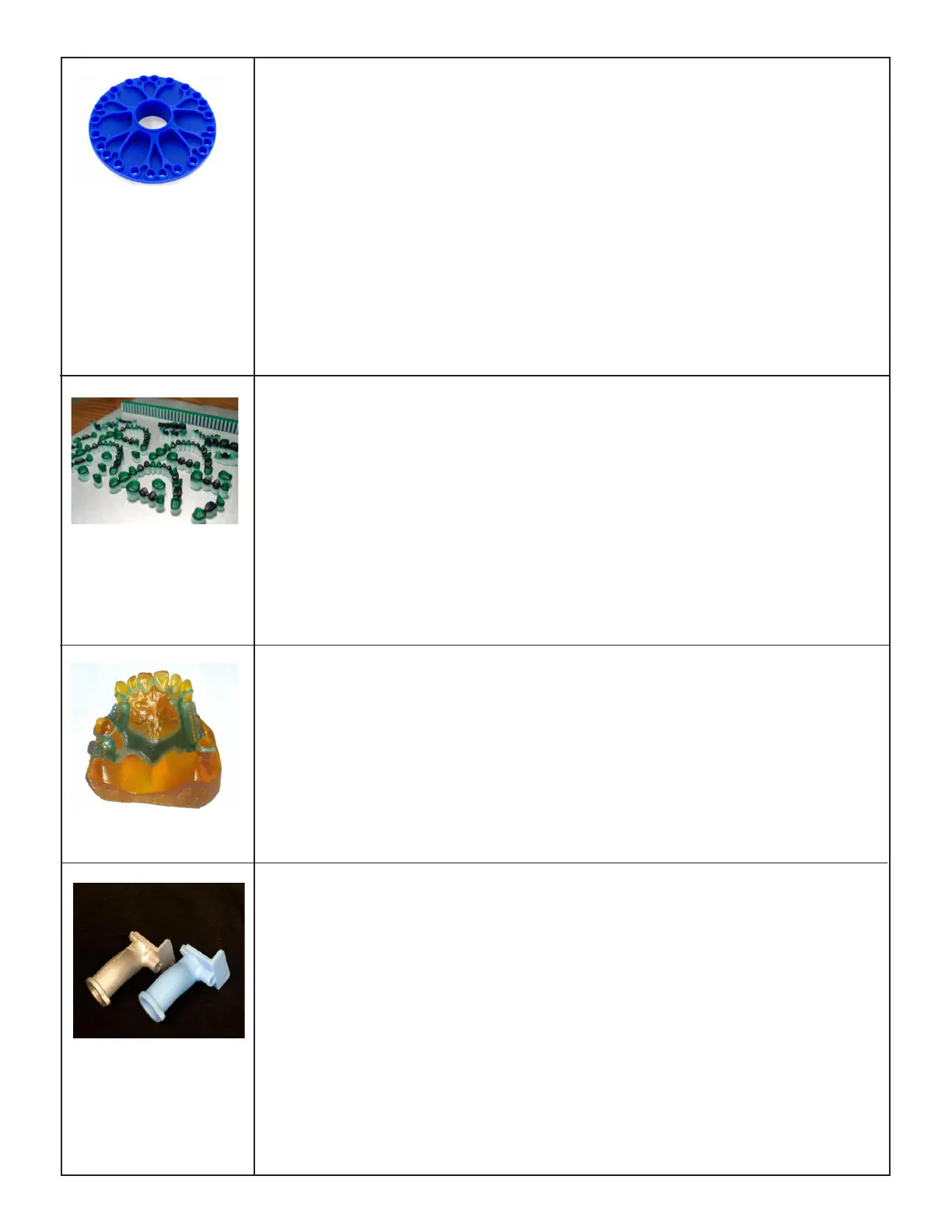

ProJet® 3510 MP can produce any size parts with smooth surfaces. Multiple parts can be built at

one time. Works with any compatible intra-oral, plaster or impression scanner. This Printing System

is designed for use in laboratories with extended unattended operation, same day processing -

helps you reduce time and cost.

Printing Mode: HDX, High Denition Plaster (HDP)

Net Build Volume (xyz): HDX & HDP Mode:11.75 x 7.3 x 8 “ (298 x 185 x 203 mm)

Resolution (xyz): HDX & HDP Mode: 375 x 375 x 790 DPI (xyz): 32μ layers

VisiJet® Materials: Part Materials: VisiJet® M3 Pearlstone, VisiJet® M3 Stoneplast;

Support Material: S300

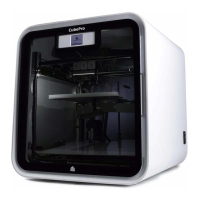

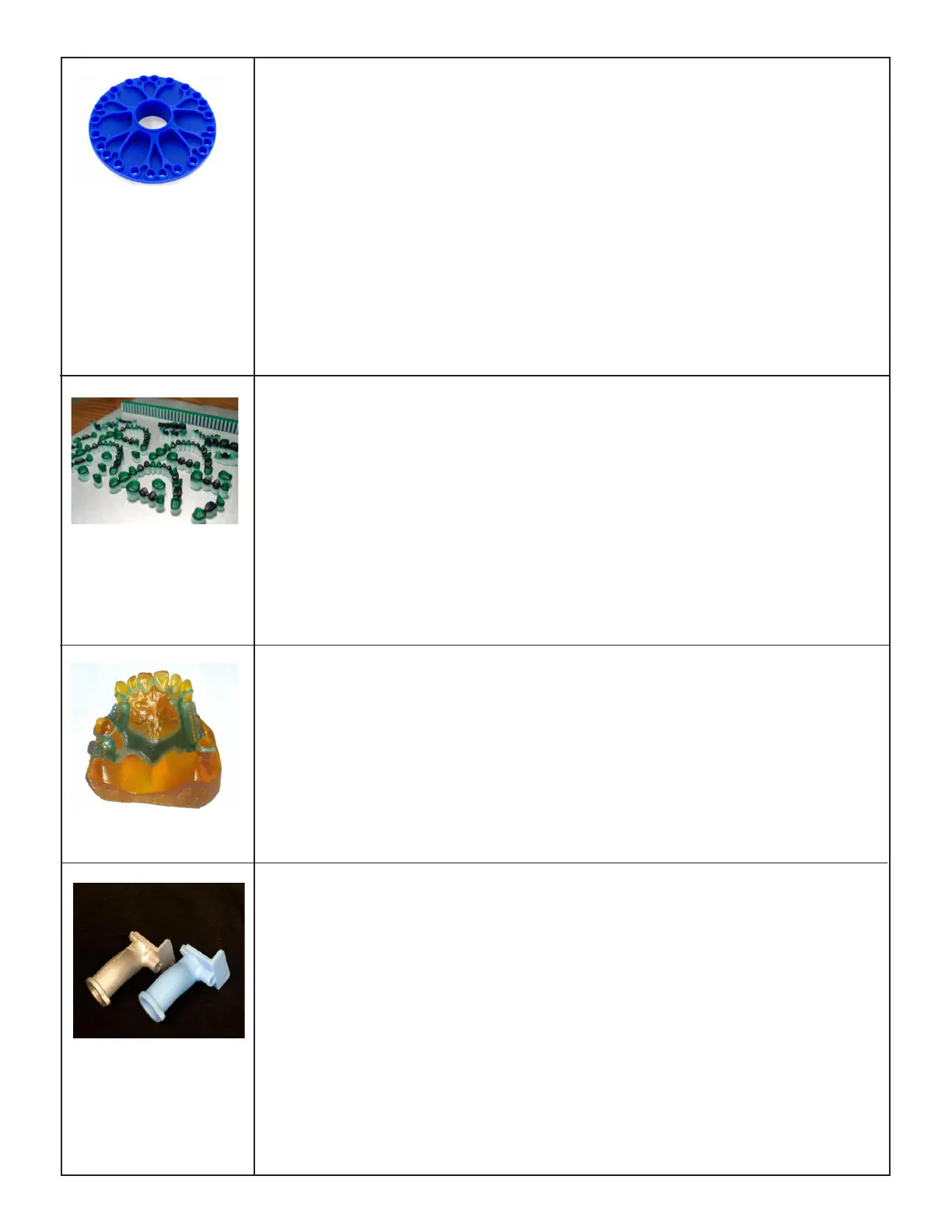

ProJet® 3510 CP mass produces 100% wax patterns with smooth surface quality and exceptional

precision, supporting almost unlimited applications capabilities. RealWax patterns are ideal for

general foundry casting applications such as medium-sized to large mechanical parts for engines,

pneumatics, aerospace, energy production and delivery, custom manufacturing equipment, resto-

rations and other heavy equipment.

Printing Mode: HD, High Denition; HiQ (HDHiQ)-High Denition

Net Build Volume (xyz): 298 x 185 x 203mm (11.75 x 7.3 x 8 inches)

Resolution (xyz): 375 x 375 x 775 DPI; 33µ layers

VisiJet® Materials: Part Materials: VisiJet® M3 ProWax, M3 Light Blue, 100% Wax; Support

Material: S400 M3

Part Stacking and Nesting: features part stacking and nesting capability in both build modes.

The user can now utilize the entire build volume by stacking parts vertically in the z-direction to ll

up the entire build envelop with parts. The user can control the space between layers to minimize

support material usage and build time. Now, hours can be saved by stacking parts and submitting

single, long builds overnight and weekends.

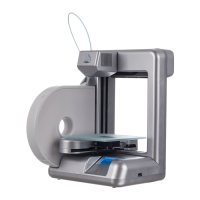

ProJet® 3510 DP accurately, consistently and economically manufactures precision wax-ups for

dental professionals. The system can generate hundreds of units each cycle. The wax-ups have

a smooth surface nish and can be cast or pressed with conventional techniques. The large build

volume and optional part stacking and nesting capabilities enable unattended operation ideal for

high-volume production.

Printing Mode: High Denition (HD); Ultra High Denition (UHD)

Net Build Volume (xyz): HD Mode: 298 x 185 x 203mm (11.75 x 7.3 x 8 inches); UHD Mode: 203

x 178 x 152mm (8 x 7 x 6 inches)

Resolution (xyz): *HD Mode: 375 x 375 x 790 DPI; UHD Mode: 750 x 750 x 890 DPI

VisiJet® Materials: Part Materials: VisiJet® M3 Dentcast; Support Material: S300

E-mail Notication: Provides e-mail notication to the user when their job begins, completes,

aborts and if the system is low on material at any time during their build. Users can set their de-

faults and make changes as to what e-mail they will receive via the Job Options window.

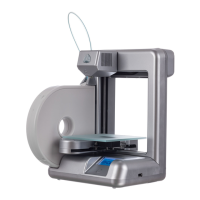

ProJet® 3510 CPXplus features a 60% expanded high denition build envelope with up to 20%

increased print speed. A new 20 micron high resolution option delivers exceptional wax patterns

with smooth surface quality and ne feature detail in less time.

Printing Mode: High Denition (HD), Ultra High Denition (UHD), Xtreme High Denition (XHD),

High Denition/High Quality (HD/HiQ)

Net Build Volume (xyz): HD Mode: 298 x 185 x 203 (11.75 x 7.3 x 8 inches); UHD Mode: 203 x

178 x 152mm (8 x 7 x 6 inches); HDHiQ: 11.75 x 7.3 x 8 inches (298 x 185 x 203 mm); XHD: 8 x 7

x 6 inches (203 x 178 x 152 mm)

Resolution (xyz): HD Mode: 375 x 375 x 775 DPI; HD HiQ: 375 x 375 x 775 DPI; 16µ layers;

33µ layers; UHD Mode: 694 x 750 x 1300 DPI; 20µ layers; XHD Mode:694 x 750 x 1600 DPI, 16µ

layers;

Materials: Part Materials: VisiJet® Hi-Cast; Support Material: S400

Email Notication: Provides email notication to the user when their job begins, completes,

aborts and if the system is low on material at any time during their build. Users can set their de-

faults and make changes as to what emails they will receive via the Job Options window.

Loading...

Loading...