963D SYSTEMS, INC. PN:80-D27 Rev.B

6. Move down the sintering piston about 5-10mm.

7. Open the airlock.

8. Open the airlock door.

9. Load the calibration plate on the sintering plate via the airlock.

10. Close the airlock door.

11. Close the airlock.

12. Launch the inerting process up to reach the fume safety level.

13. Download the specic manufacturing FAB le on the printer.

14. Start the draw (layer#0) of the calibration plate with the red point in order to control its positioning. Adjust the

calibration plate if necessary.

15. Start the draw (layer#0) of the calibration plate without the red point.

16. Repeat the previous step, to be sure the draw will be well marked.

17. When job is complete, repeat steps from 6 to 8 to remove the calibration plate from the printer via the airlock.

18. Close the airlock door and airlock. Then stop the inerting process.

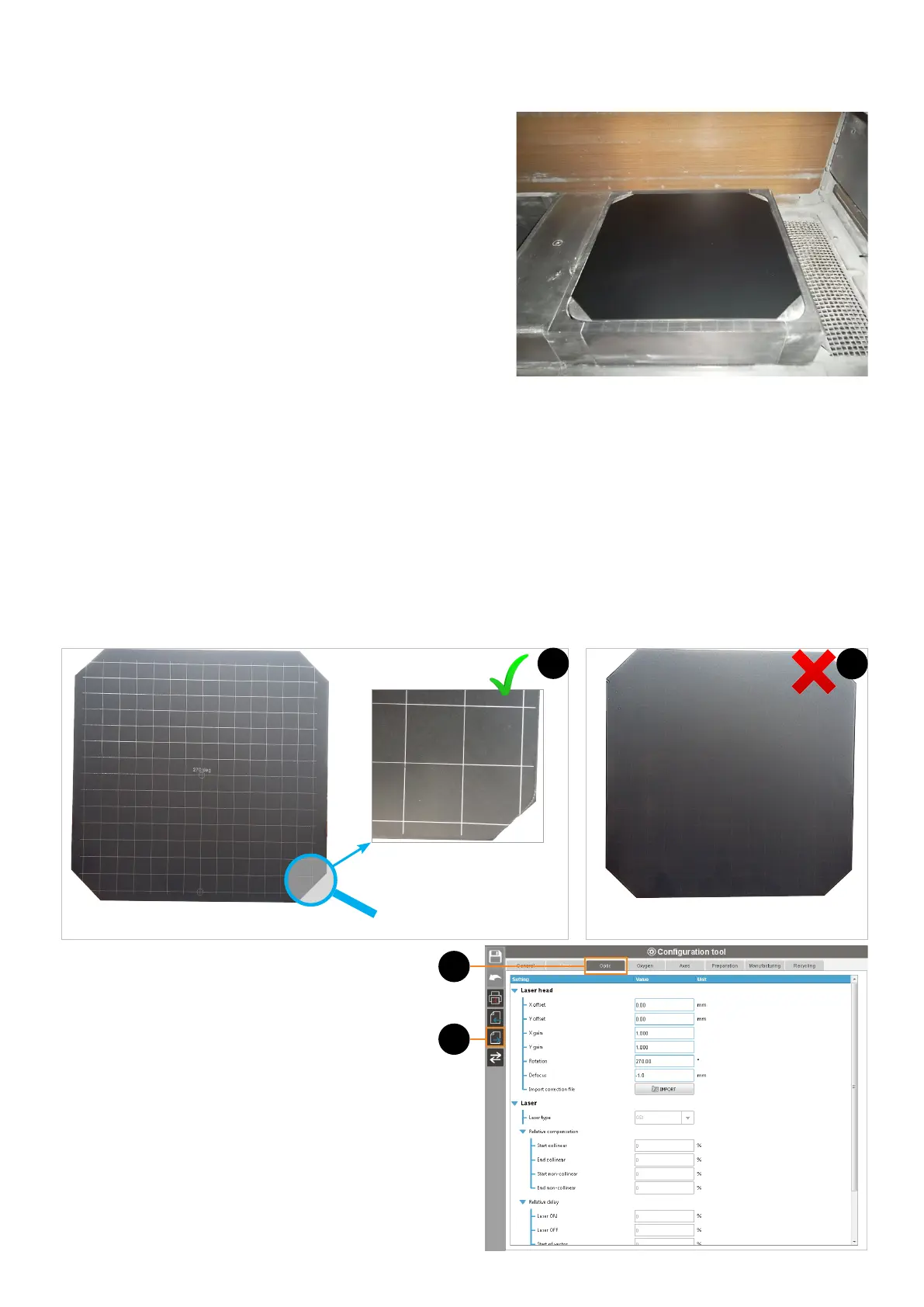

19. Inspect visually the sintered lines are homogeneously well marked over the whole surface of the plate (1). If the result is

not correct (2), repeat the draw on a new calibration plate. If the result is still no correct, contact 3D Systems Customer

Support.

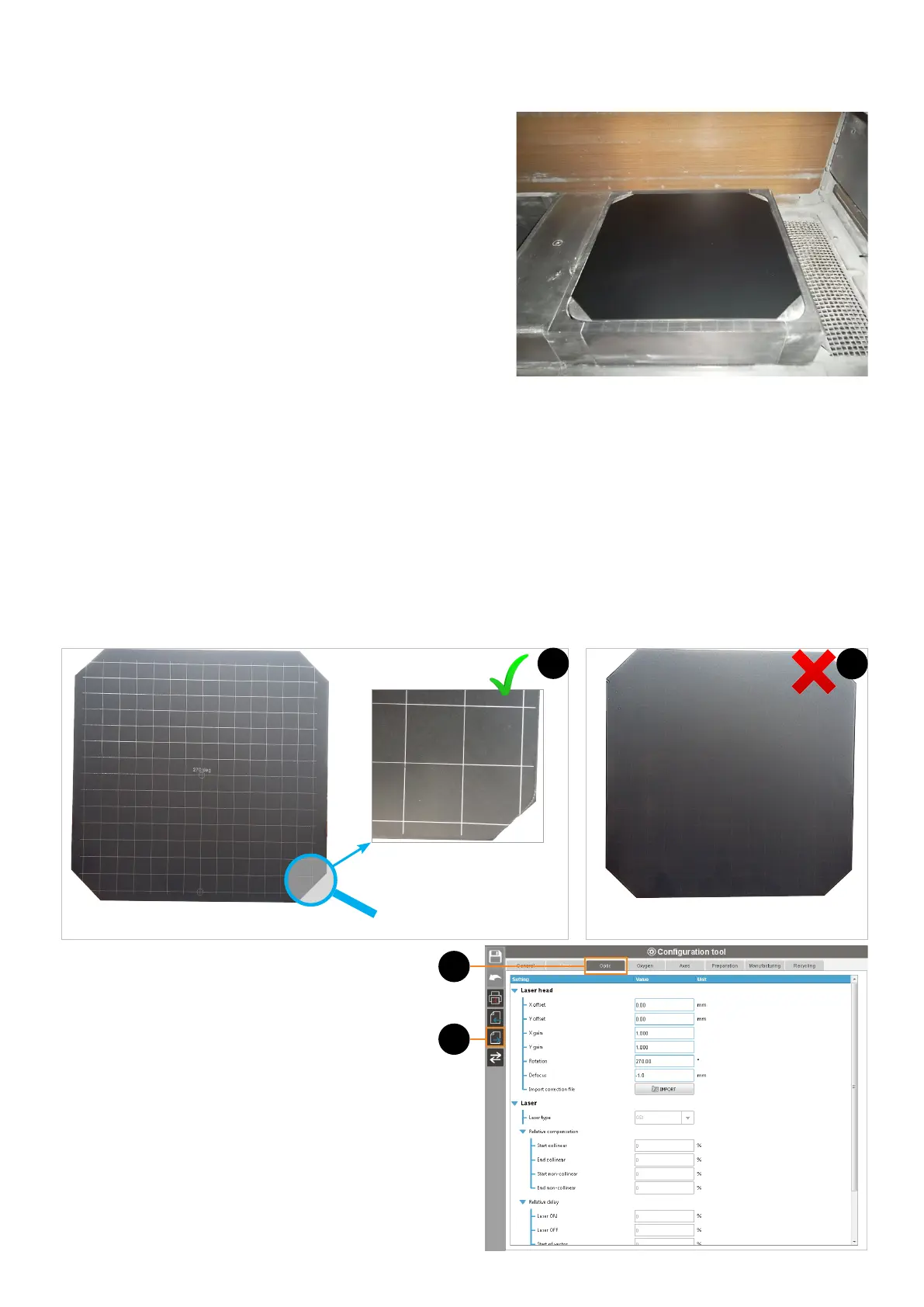

20. The control of the calibration requires the current

correction le. To export this correction le:

• Access to the Conguration tool,

• Go to the Optic menu (1),

• Click on the Export button (2),

• Select "Correction le" from the le list, then save

the le on a folder from your network or a USB

key.

2

1

Calibration plate with crossing-lines homogeneously well marked

1

Calibration plate with crossing-lines

not marked correctly

2

Loading...

Loading...