643D SYSTEMS, INC. PN:80-D27 Rev.B

UNLOADING A PLATE

Operations described below complement and follow on from the Preparation Assistant "Step 2 : Unloading plate" on page

40.

WARNING : REACTIVE POWDER

THE MANUFACTURING CHAMBER MUST BE INERT BEFORE POWDER MANIPULATION (O

2

LEVEL 1%

MAXIMUM).

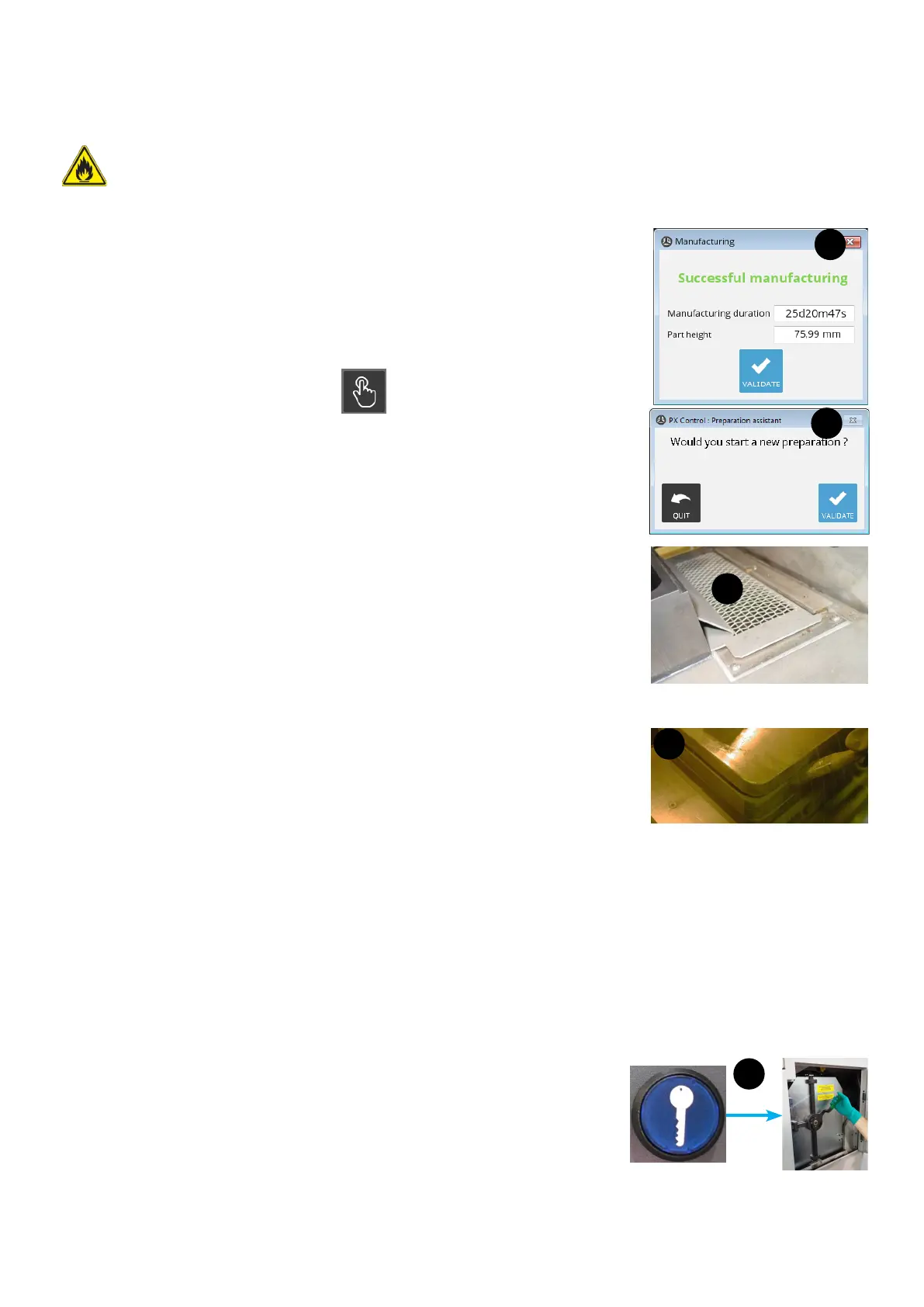

1. When a job is complet, the control panel will display the job time and the part height.

Click on “Validate” to quit the end job window (1).

2. Click on the Preparation Menu button

.

3. Click on "Validate" to conrm (2).

4. Proceed to the step#1 of the Preparation Assistant (see "Step 1 : Initialization" on

page 40 for details).

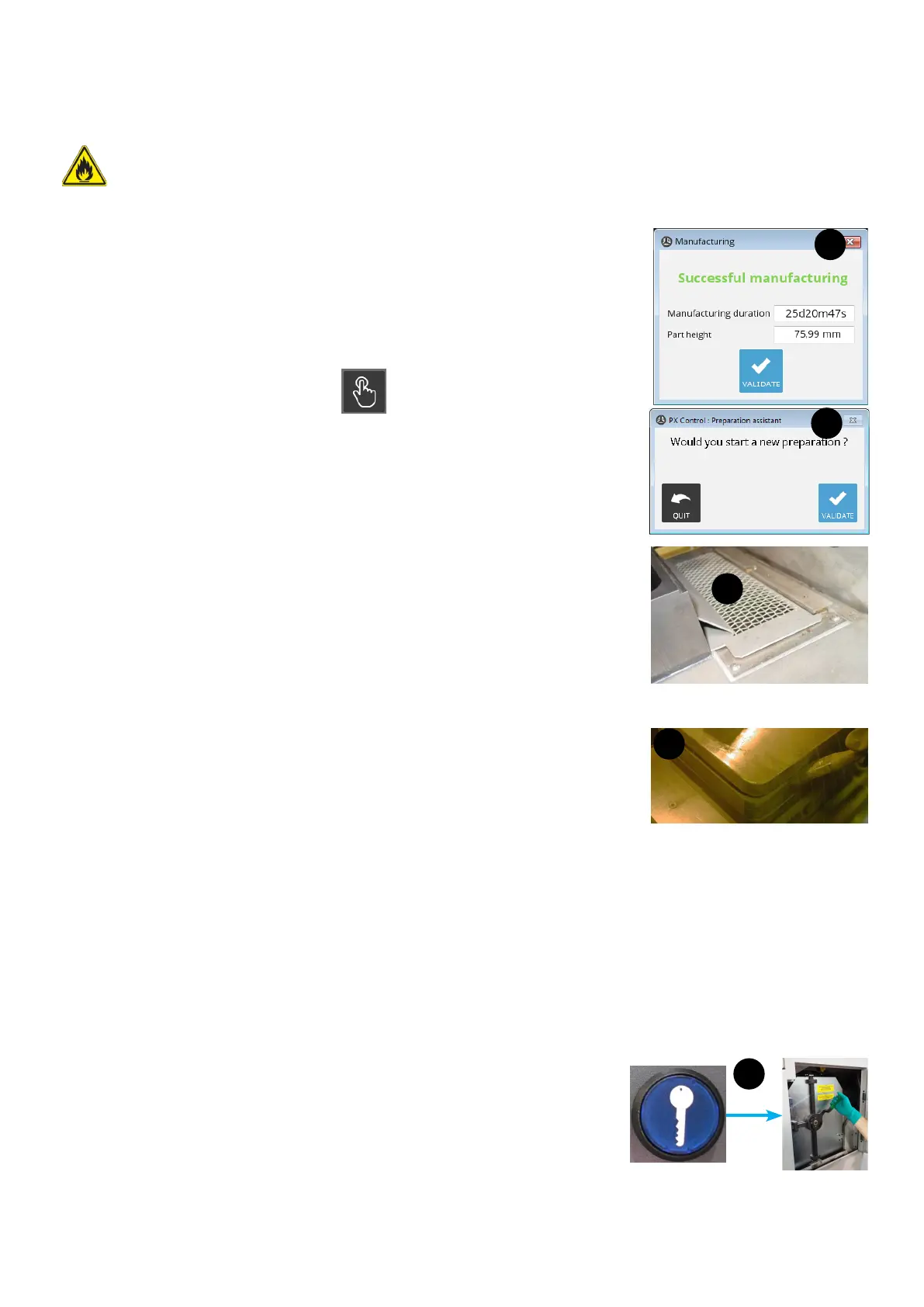

5. Sintering plate cleaning :

• Clean the sintering plate with the brush by sweeping any un-sintered powder

from left to right towards the collecting tank (3).

• With the vacuum cleaner, nish the cleaning of the sintered plate.

• Raise the sintering piston to the upper position in order to see the groove.

• Clean the groove between the sintering plate and the plate support to help tighten the jaws during the plate

unloading (4).

6. Plate unloading and carriage cleaning:

• Launch the “Unloading plate” cycle.

• Activate the sleeve cleaner and move up and down the scraper.

• Position the carriage at a position >700mm and clean it.

• Unlock the door and open the glove door.

• Switch on the vacuum.

• Clean the carriage with the vacuum and the brush. When complete, wind the vacuum.

• Switch off the vacuum.

• Close the glove door.

• Press the unlock door button. The door is still locked during the next 10

seconds. After the 10 seconds, open the airlock door (5).

• Pull the carriage from the airlock.

• Remove the whole plate from the carriage.

• Push the carriage inside the airlock.

• Close the airlock door.

1

2

3

4

5

10s

Loading...

Loading...