23D SYSTEMS, INC. PN:80-D27 Rev.B

GENERAL MACHINE OPERATION

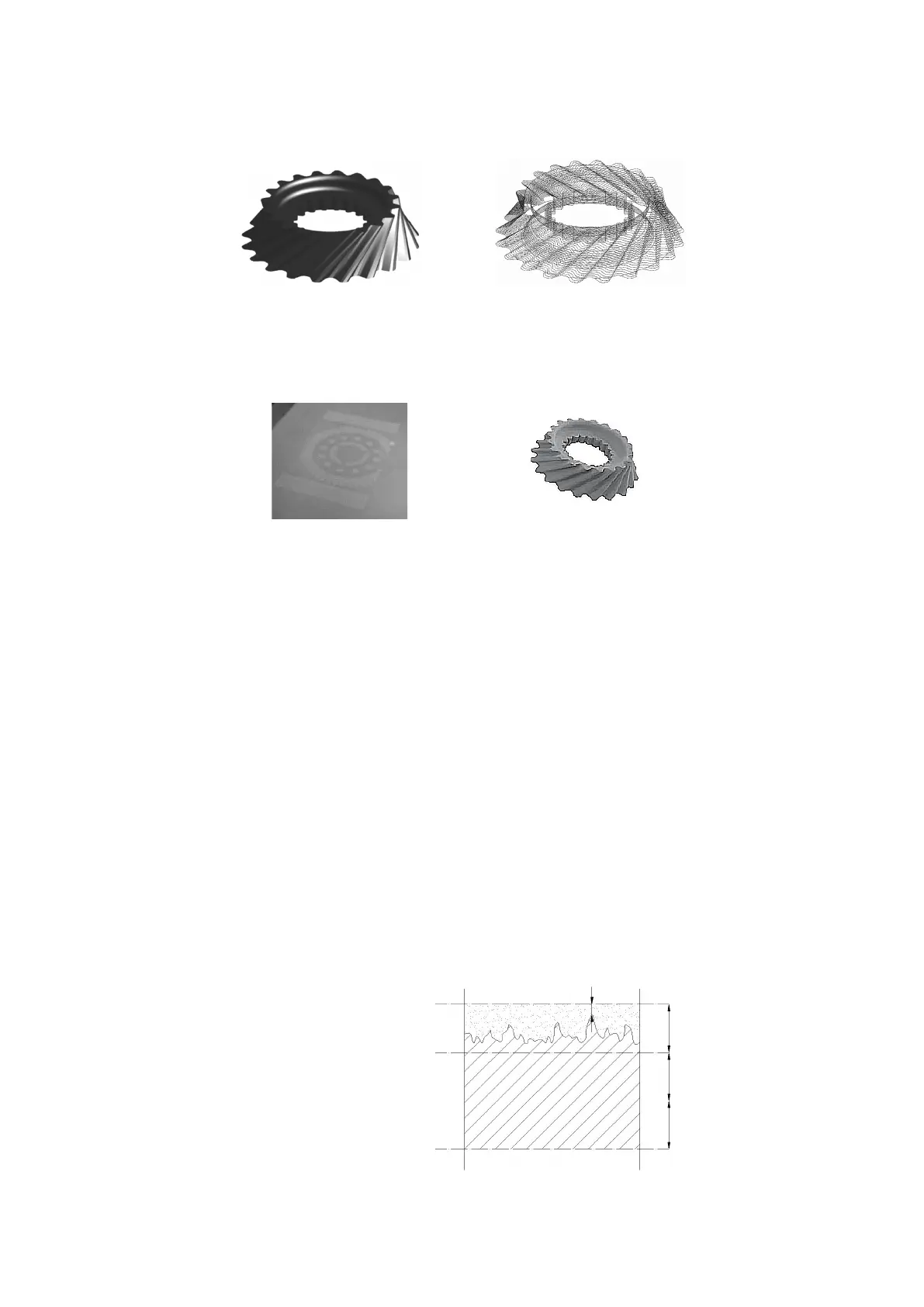

The manufacturing process takes place as follows:

• Processing of the CAD le with ProX DMP Manufacturing, standalone software, in order to slice the part as a series of

superimposed cross-sections. Creation of the manufacturing le (*.FAB2, or *.FAB3 les), used by the ProX

®

DMP metal

printers.

• Preparation of the machine, loading of the sintering plate and purging the chamber.

• Uploading the *.FAB2 or *.FAB3 le onto the machine.

• Dispensing a powder layer on the sintering plate (Layering cycle).

• Fusing the metal powder into a solid part using a focused laser beam (Sintering cycle).

• Repeated execution of layering and sintering cycles until the part is produced.

• Unloading the part and possible post-processing and nishing in order to obtain the desired characteristics.

INTENDED USE

Laser sintering operations are performed on metal powders only.

Each metal powder should only be used after checking the information provided by the supplier, the material safety data

sheet (MSDS) and any applicable regulations.

Limitations relating to the manufacture of 3D objects by laser sintering

Before manufacturing a 3D object, please ensure that none of the following criteria are met :

• A 3D object with at least one of the layers covering more than half of the total surface of the sintering plate,

• 3D object with an undercut angle< 45 ° compared to the horizontal surface of the sintering plate,

• 3D object where its minimum thickness is 5 times smaller than its height,

Without being exhaustive, these criteria represent the majority of cases to be checked before manufacturing a 3D object by

laser sintering.

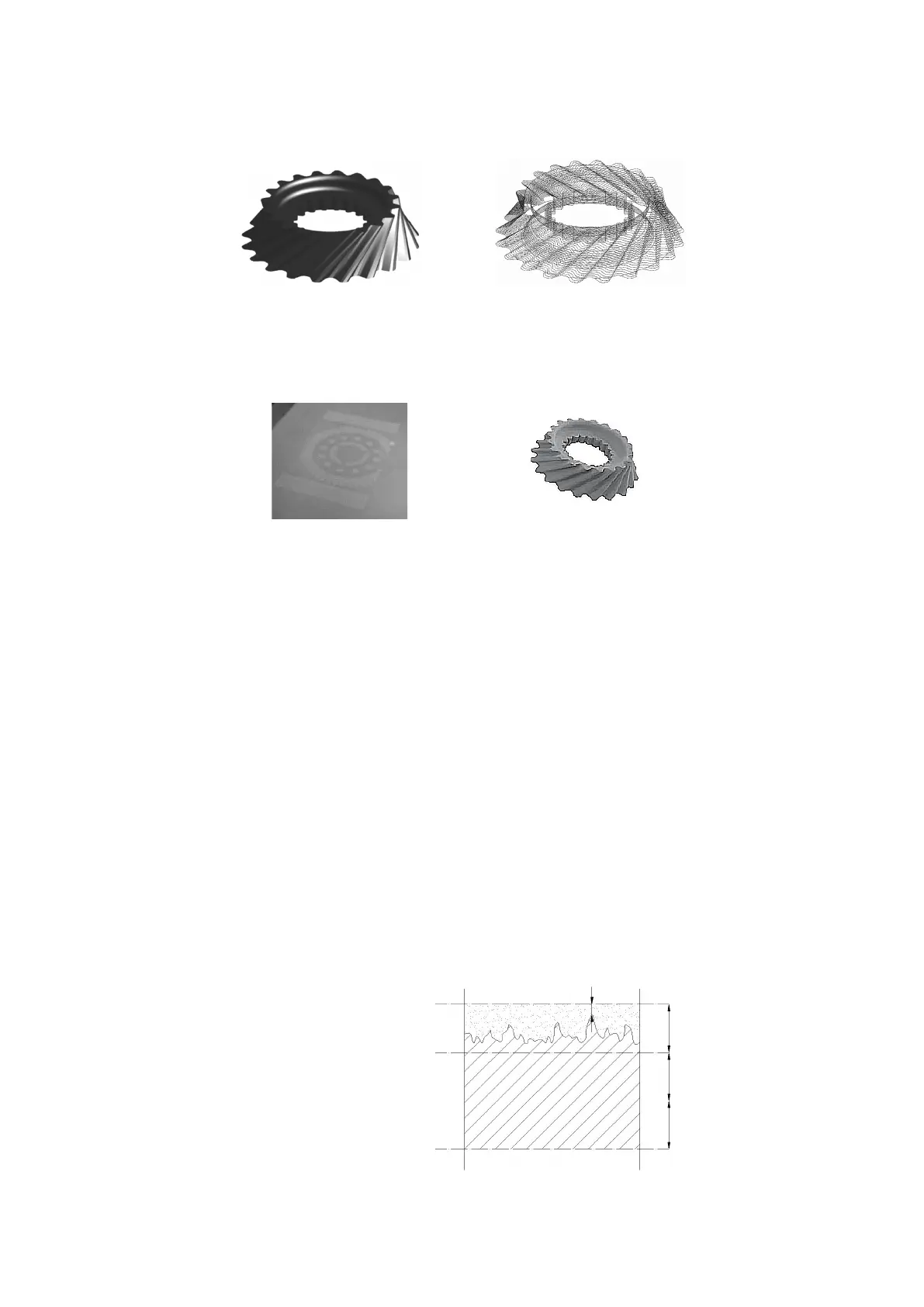

Conditions relating to the Layering

During the manufacturing process, the roller must not disturb any of the previous sintered layers. This is why the correct

conditions required for the manufacturing of layers is given in the following diagram.

C

n

C

n-1

C

n-2

e ≥ 0

C : thickness of layers (c = c

n-1

= c

n-2

...)

Loading...

Loading...