693D SYSTEMS, INC. PN:80-D27 Rev.B

Process lter (external lter)

The lens cleaner lter must be changed every 1500 hours (2 months continuous 24/7 operation).

The ProX

®

DMP300 is equipped with a lens cleaner ltering unit that prevents fumes and dust generated by the sintering

process from being deposited on the lens. If this lter becomes clogged, the gas will not ow as eciently as it should and

may result in reduced sintering quality. Moreover, the step-by-step instructions identify the potential lter replacement

hazards and must be understood by the trained operators.

This procedure must be followed to ensure ecient sintering during the machine operation and also the operator’s safety

during maintenance. 3D Systems recommends that you execute this procedure as written and have a Class D extinguisher

available when performing this procedure.

WARNING : WEAR PPE DURING HANDLING OPERATIONS (REFER TO MSDS OF MATERIAL). WEAR A NON-

ELECTROSTATIC SUIT.

WARNING : RISK OF FIRE AND EXPLOSION.

THIS MAINTENANCE HAS TO BE DONE PROPERLY AND CAREFULLY. IF THIS MAINTENANCE IS NOT

PROPERLY DONE, IT CAN CAUSE DAMAGE TO THE MACHINE OR THE USER. USE THE NECESSARY TOOLS AND

WEAR THE CORRECT PROTECTION. THIS IS A TWO PERSON JOB.

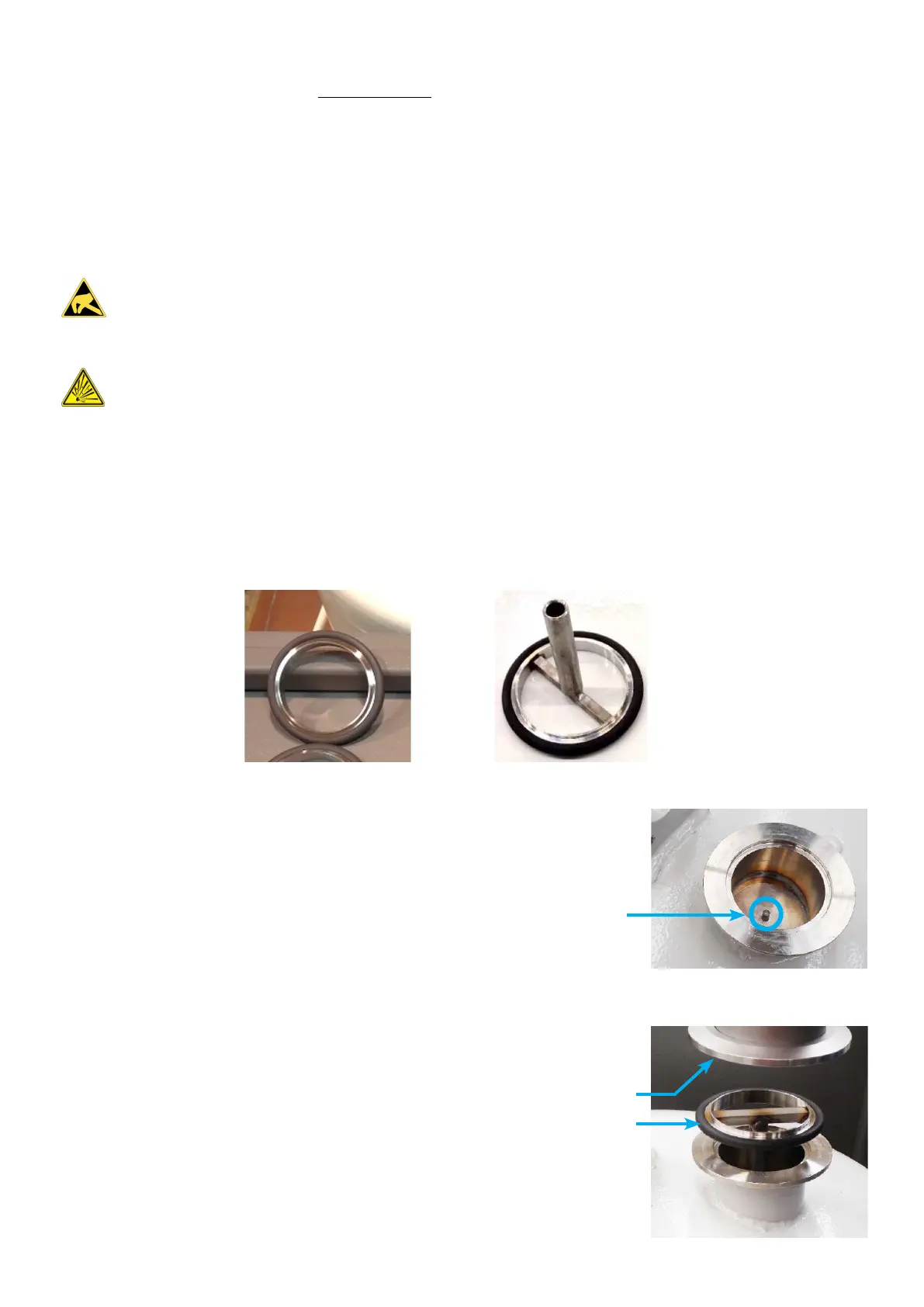

Centering rings

There are two types of centering ring used on the disposable process lter:

• The rst type is a standard centering ring that will be used for the lter replacement. 2 standard centering rings are

supplied with the process lter crate, and should be stored for later use (lter replacement).

• The second type is a centering ring with stand-off tube. These rings are already mounted on the lter, one on each

port of the lter.

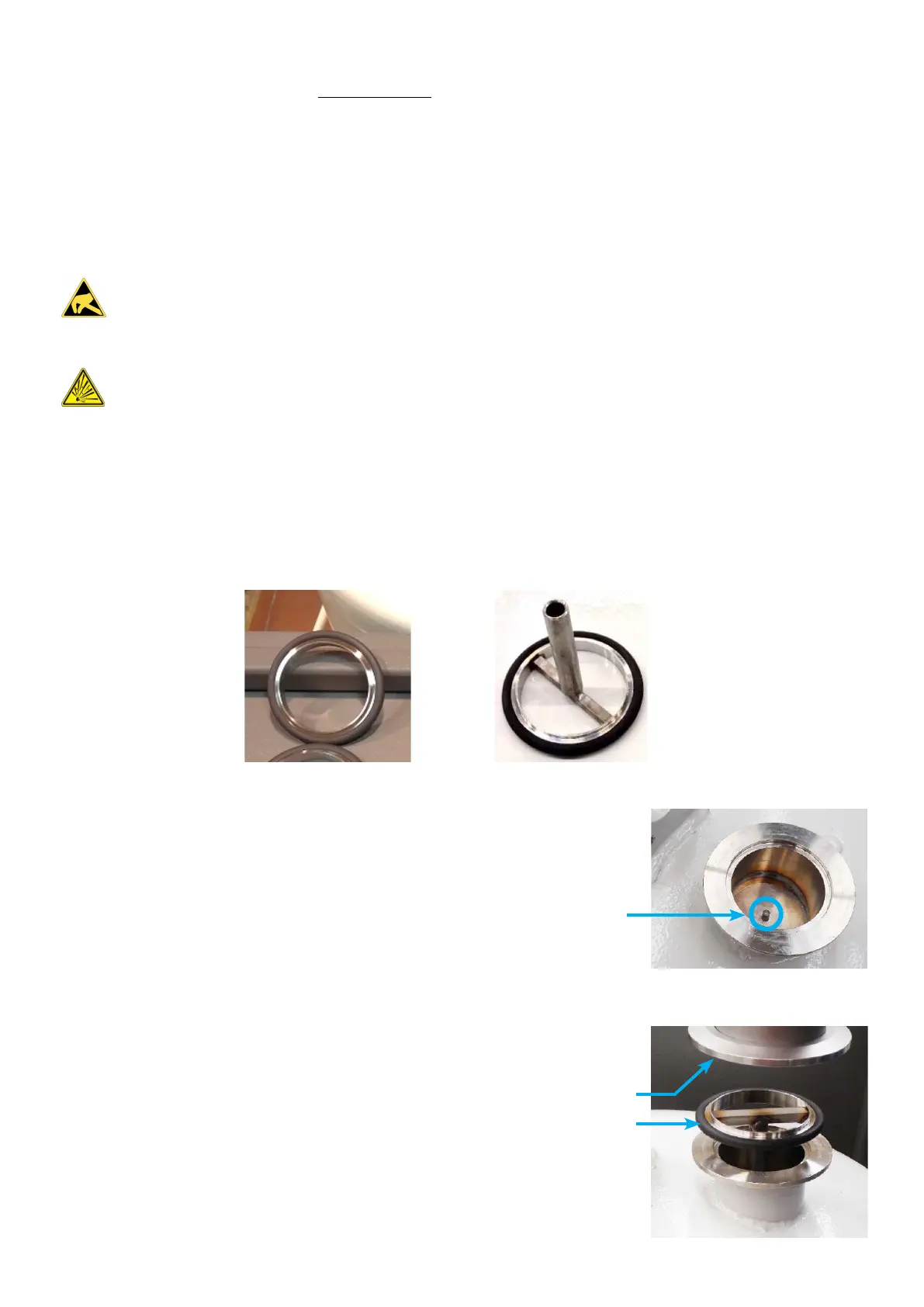

The inlet and outlet ports of the lter are equipped with a spring-loaded valve. When the

lter is not connected to the printer, these valves keep the ports normally closed and

thereby prevent air from entering the lter. The adjacent gure shows the top of the

internal valve in the lter outlet port. When installed, the stand-off of the centering ring is

placed directly on the locating pin of the valve.

The external pneumatic valve is placed directly on top of the centering ring with stand-off

and pressed down until the anges meet. This creates the seal between the two parts and

the centering ring with stand-off holds the spring-loaded valve open for normal operation.

The connection is secured with a clamp.

Locating pin

Standard centering ring

Centering ring with stand-off tube

Centering ring with stand-off tube

Pneumatic valve

Loading...

Loading...