263D SYSTEMS, INC. PN:80-D27 Rev.B

A. Chamber door

The operator accesses the inside of the chamber through the two glove ports located on the front face of the machine.

The sliding door must be opened to access the glove ports (see section "Loading the feeding piston" on page 57). Two

interlocks, on the sliding door and on the gloves door, block all movements (tamping module, carriage, etc…).

The chamber is equipped with a laser safety window.

850nm≤λ≤1100nm DLB5 - IRLB8 - CE EN207

The door provides access to the entire chamber only for maintenance.

Only qualied personel may operate the machine with the chamber door opened

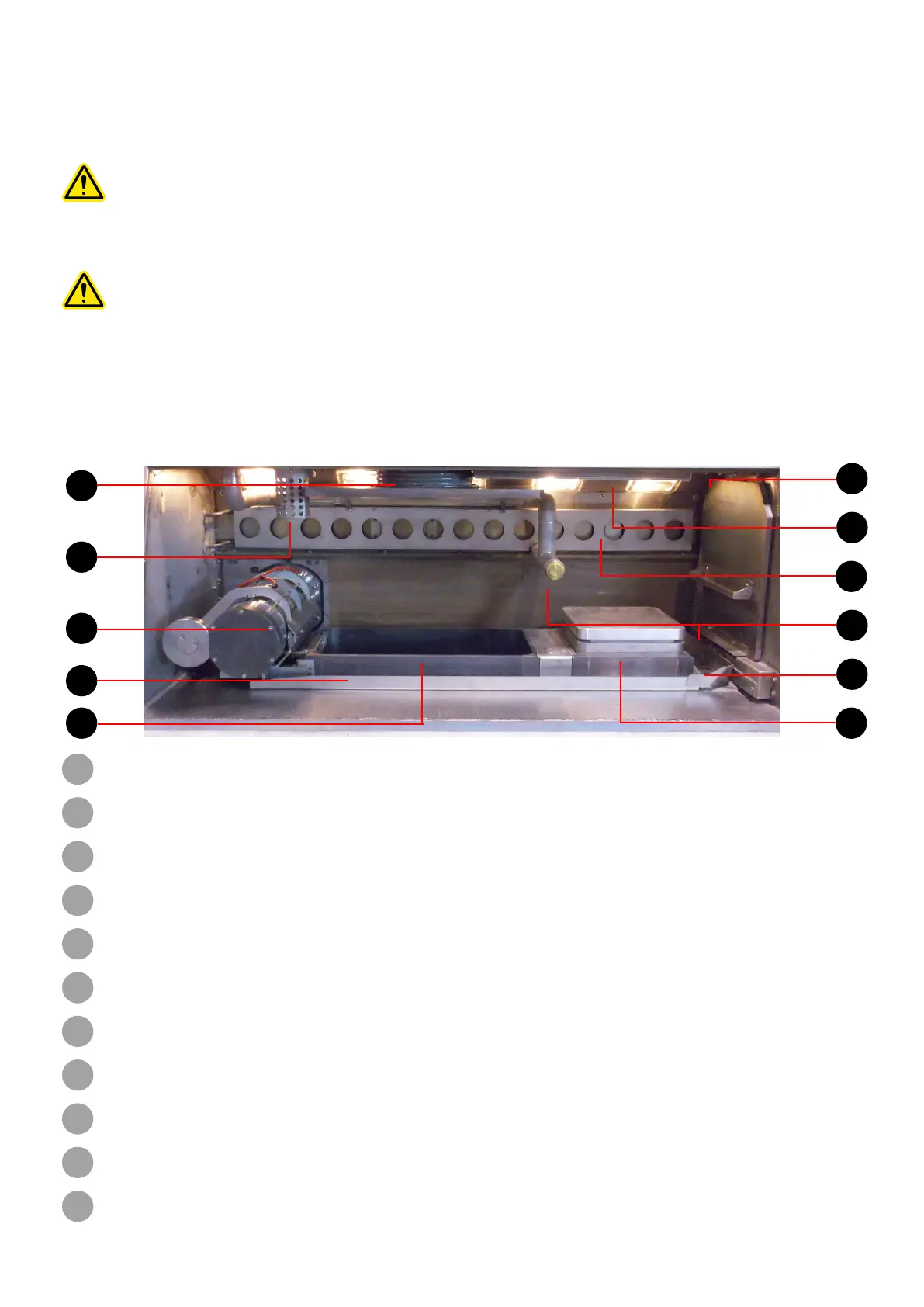

B. Manufacturing chamber

The direct metal printing takes place in the manufacturing chamber, which is kept under a controlled inert atmosphere

during the printing process.

The manufacturing chamber consists of :

1

LAYERING MODULE (SEE SECTION "1. LAYERING MODULE" ON PAGE 27)

2

FEEDING PISTON (SEE SECTION "2. FEEDING PISTON" ON PAGE 27)

3

SINTERING PISTON (SEE SECTION "3. SINTERING PISTON" ON PAGE 27)

4

COLLECTING TANK (SEE SECTION "4. COLLECTING TANK" ON PAGE 27)

5

FUMES CLEANER DEVICE (SEE SECTION "5. FUME CLEANER DEVICE" ON PAGE 28)

6

HEATING ELEMENT (SEE SECTION "6. HEATING ELEMENT" ON PAGE 28)

7

OXYGEN ANALYSER SENSOR (SEE SECTION "7. OXYGEN ANALYSER SENSOR" ON PAGE 28)

8

POWDER TAMPING MODULE (SEE SECTION "8. POWDER TAMPING MODULE" ON PAGE 28)

9

LENS CLEANER AND LENS TRAP (SEE SECTION "9. LENS CLEANER AND LENS TRAP" ON PAGE 28)

10

VACUUM CLEANER (SEE SECTION "10. VACUUM CLEANER" ON PAGE 28)

11

POWDER GUTTER (RECOVERY POWDER SYSTEM)

1

2 3

4

5

6

7

9

8

10

11

Loading...

Loading...