93D SYSTEMS, INC. PN:80-D27 Rev.B

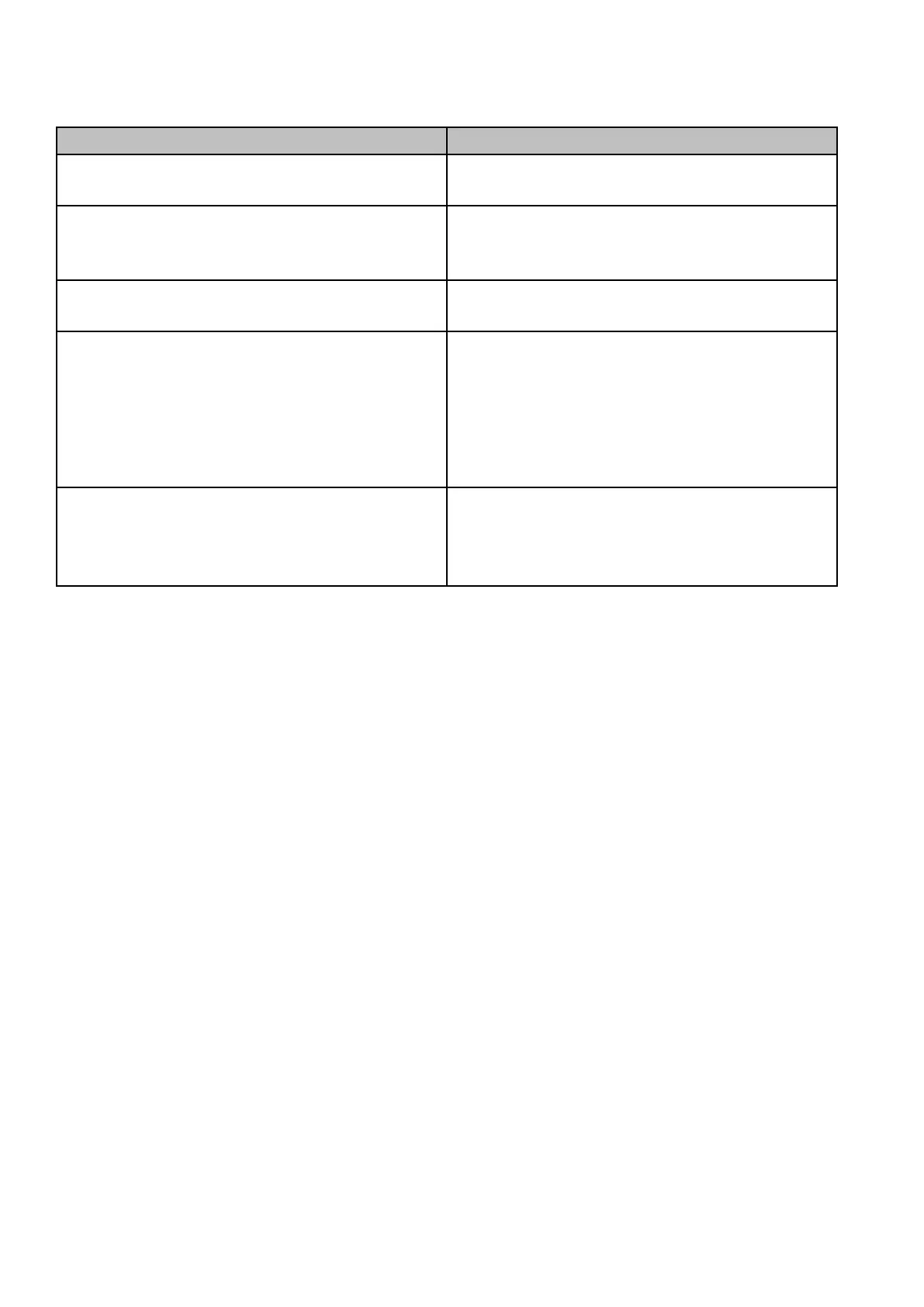

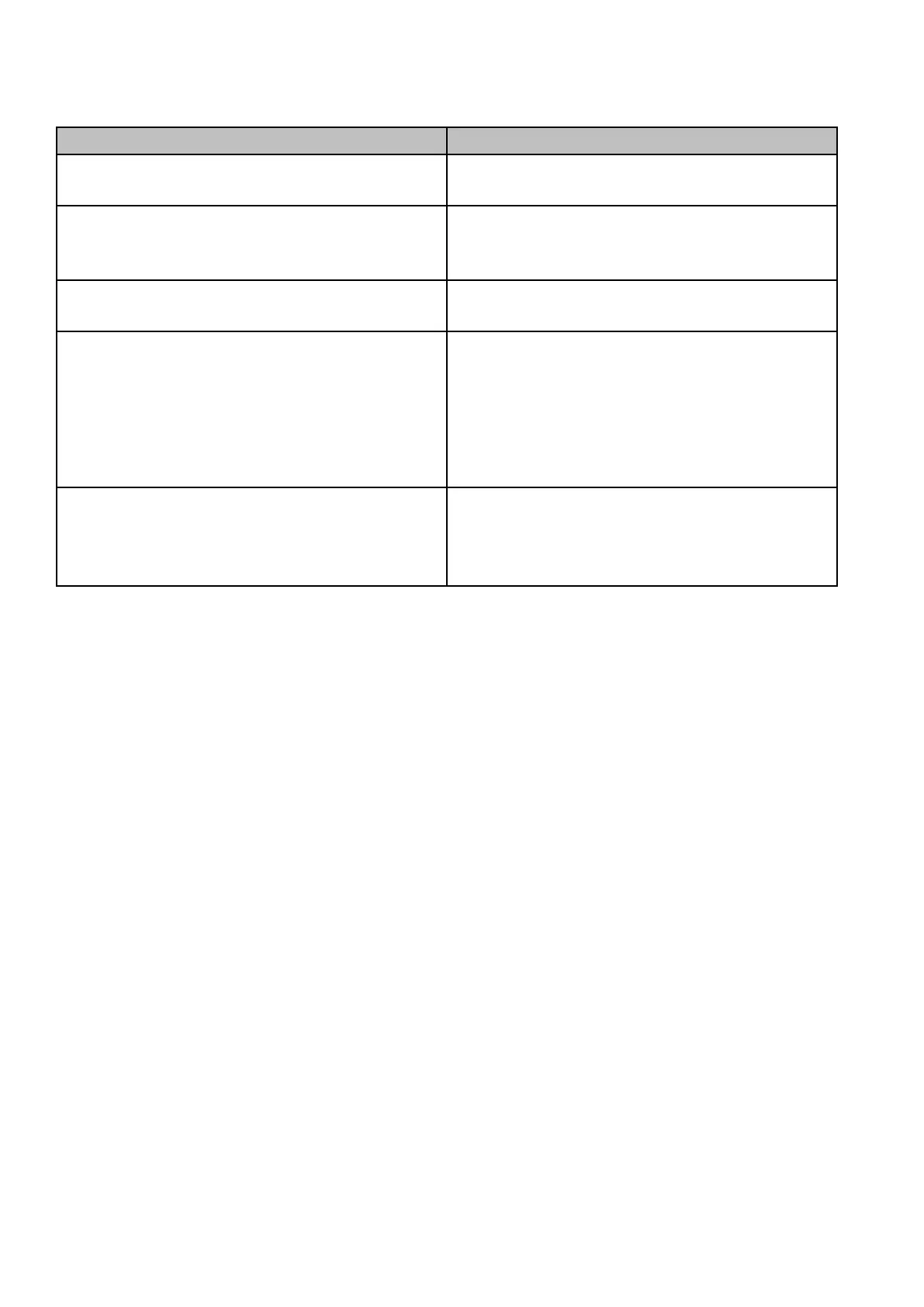

DMP System Response if an Interlock Fails

Safety interlock devices mounted on the DMP system sense the hazardous operating conditions below. The DMP system

takes the actions listed when an interlock fails.

SAFETY INTERLOCKED CONDITION IF THIS INTERLOCK FAILS...

• For all conditions • No job will start

• Warning message appears on DMP system display

• External/internal sliding front doors are open

• Airlock door open

• Orange stacklight illuminates

• Laser interlock activated

• Supply of the motors is cut off (400V)

• Chamber front door open

• Scan head access door open

• Laser interlock activated

• Right/left side panels open

• E-Stop

• Supply of the motors is cut off (400V)

• Laser power cut off

• 230V actuators cut off (sieving, blowers, light, oven,

vacuum cleaner recoiler, vibrating channel)

• Pneumatic actuators stopped (airlock, tamping,

scraper)

• Red stacklight illuminates

• Oxygen in process chamber too high • No job will start

• Warning message appears on DMP system display

• Blowers not operating.

• Process lter valves closed

Limited Access and Barrier Shielding

DMP equipment frame and enclosure designs limit access to the following:

• Service areas, such as cabinets and enclosures for electrical power and automation controls. This prevents accidental

exposure to electrical shock hazards.

• Material areas, such as material feed hoppers. This prevents:

• burn hazards by minimizing exposure to heated material

• slip hazards by preventing material from spilling onto the oor

• re hazards by minimizing airborne dust cloud formation and potential ignition. See SDS for complete material

hazard details.

• Laser beam optics and scanning areas, including the fully-enclosed print head—where the laser beam originates—

and the interior of the print chamber, into which the beam projects. The scan head and chamber are designed to mini-

mize hazards such as burns, eye injury, and re in the following ways:

• The scan head optics and laser beam duct (at the top of the chamber) prevents the laser beam from being aimed

outside the print chamber.

• The fully enclosed chamber blocks laser radiation from escaping to the outside.

• The material of the chamber window, which conforms to CE EN207, also blocks laser radiation so you can safely

observe the part during a print.

Loading...

Loading...