883D SYSTEMS, INC. PN:80-D27 Rev.B

Vibrating channel enclosure cleaning

The vibrating channel must be cleaned every 6 months. It is located below the recycling lter.

Part required :

• Vacuum cleaner equipped with wet separator and be explosion proof.

• Natural ber brush

• Damp cotton cloth

Caution: Personal Protective Equipment (PPE) must be used to protect the user against health or

safety risks during working tasks. Wear disposable rubber gloves, anti-static coverall, anti-static safety

shoes and safety glass. Wear disposable dust mask rated FFP3 or N99 level protection at minimum ; we

recommand the use of powered air purifying respirator.

Caution: do not perform the maintenance while an automatic cycle is operating (recycling, loading,

unloading, inerting cycle).

Procedure:

1. Make sure the gas and purge are not activated.

2. Open the left side access door.

When the side door is opened and if the printer is still powered up,

the status of the interlock prevents the printer to operate during the

maintenance (see "DMP System Response if an Interlock Fails" on

page 9).

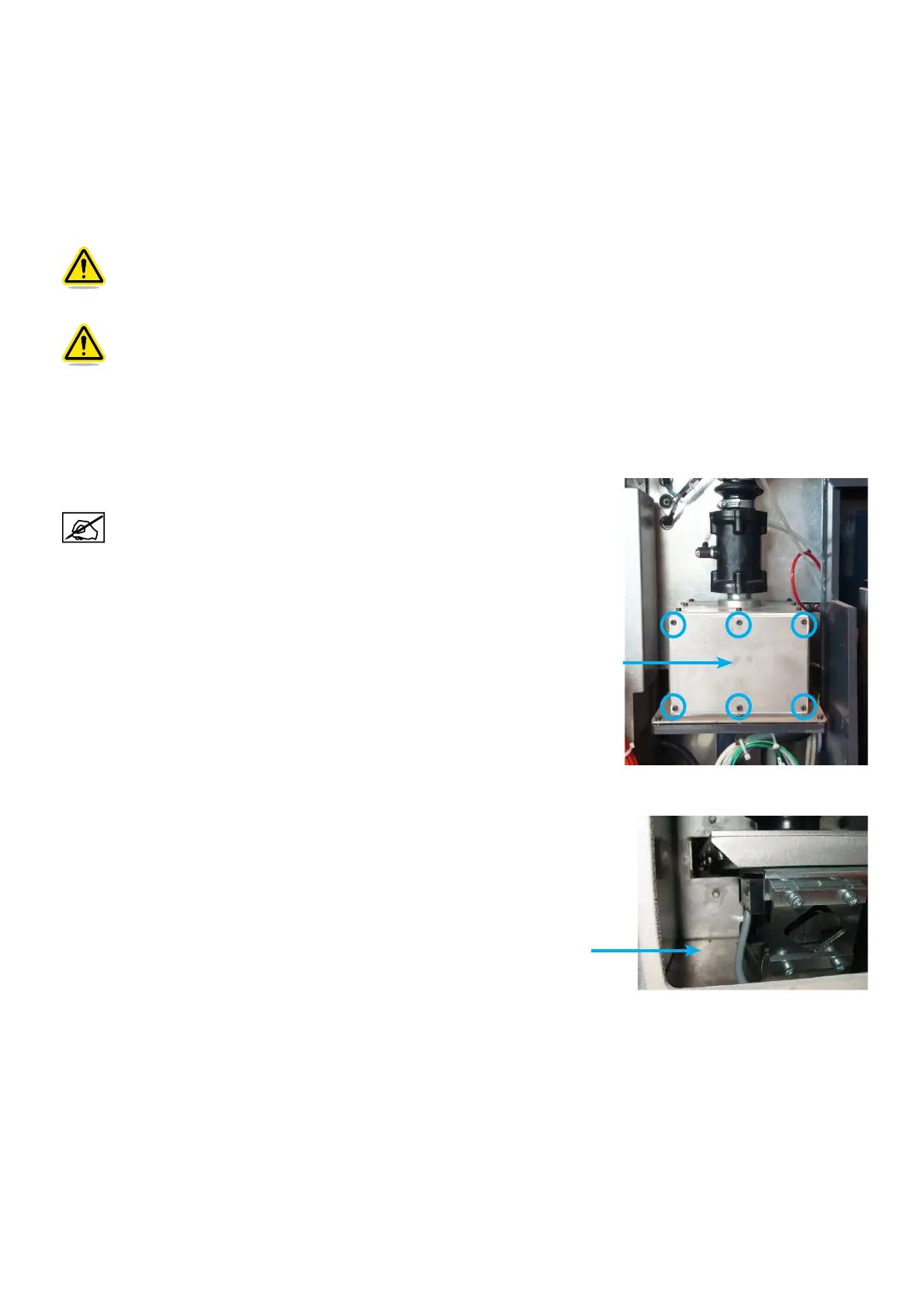

3. Remove the screws holding the cover plate of the vibrating channel.

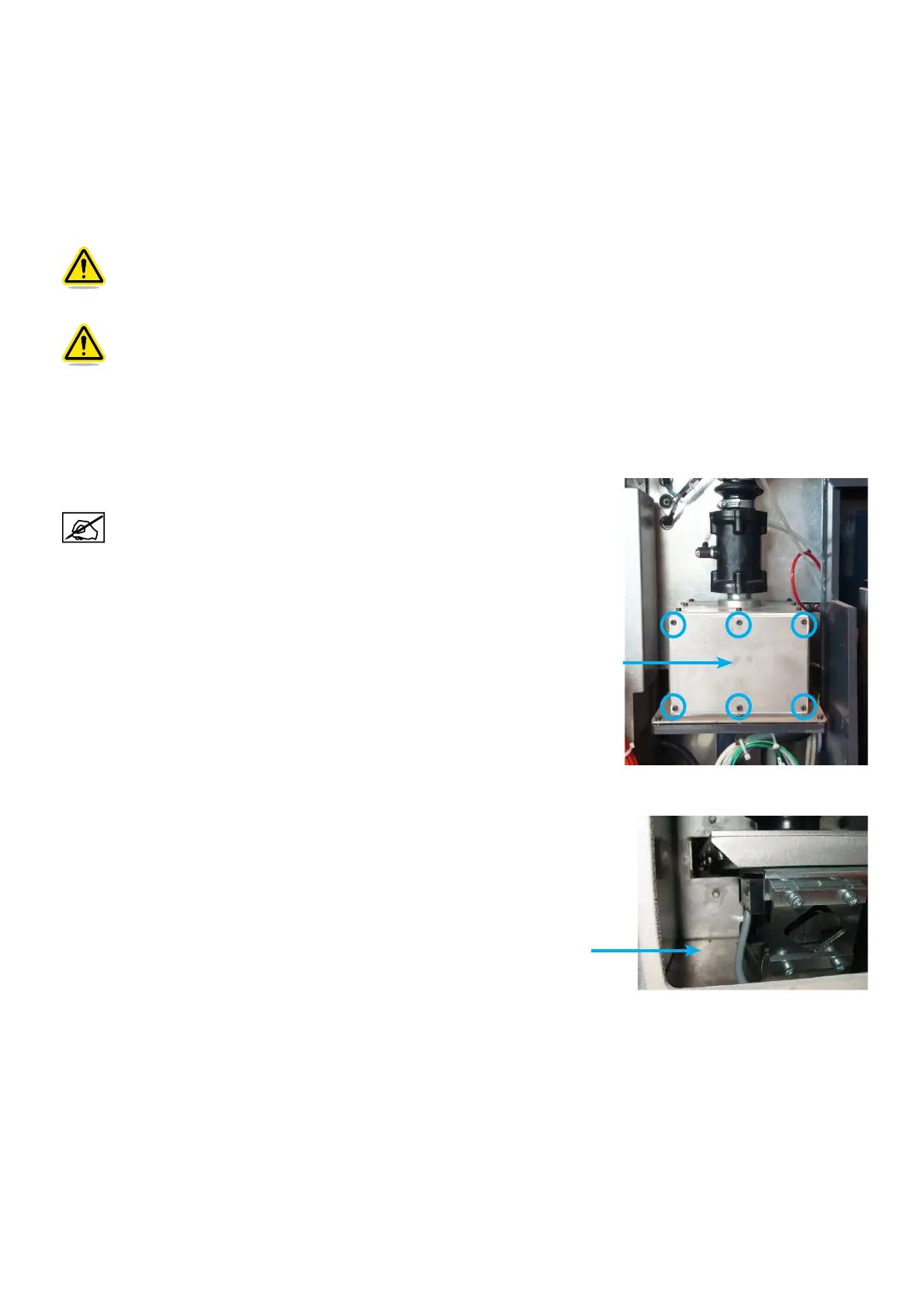

4. Clean inside the vibrating channel with the use of a brush and vacuum cleaner.

5. Replace the cover plate of the vibrating channel.

6. Close the left side access door.

Cover plate

Cleaning area

Loading...

Loading...