633D SYSTEMS, INC. PN:80-D27 Rev.B

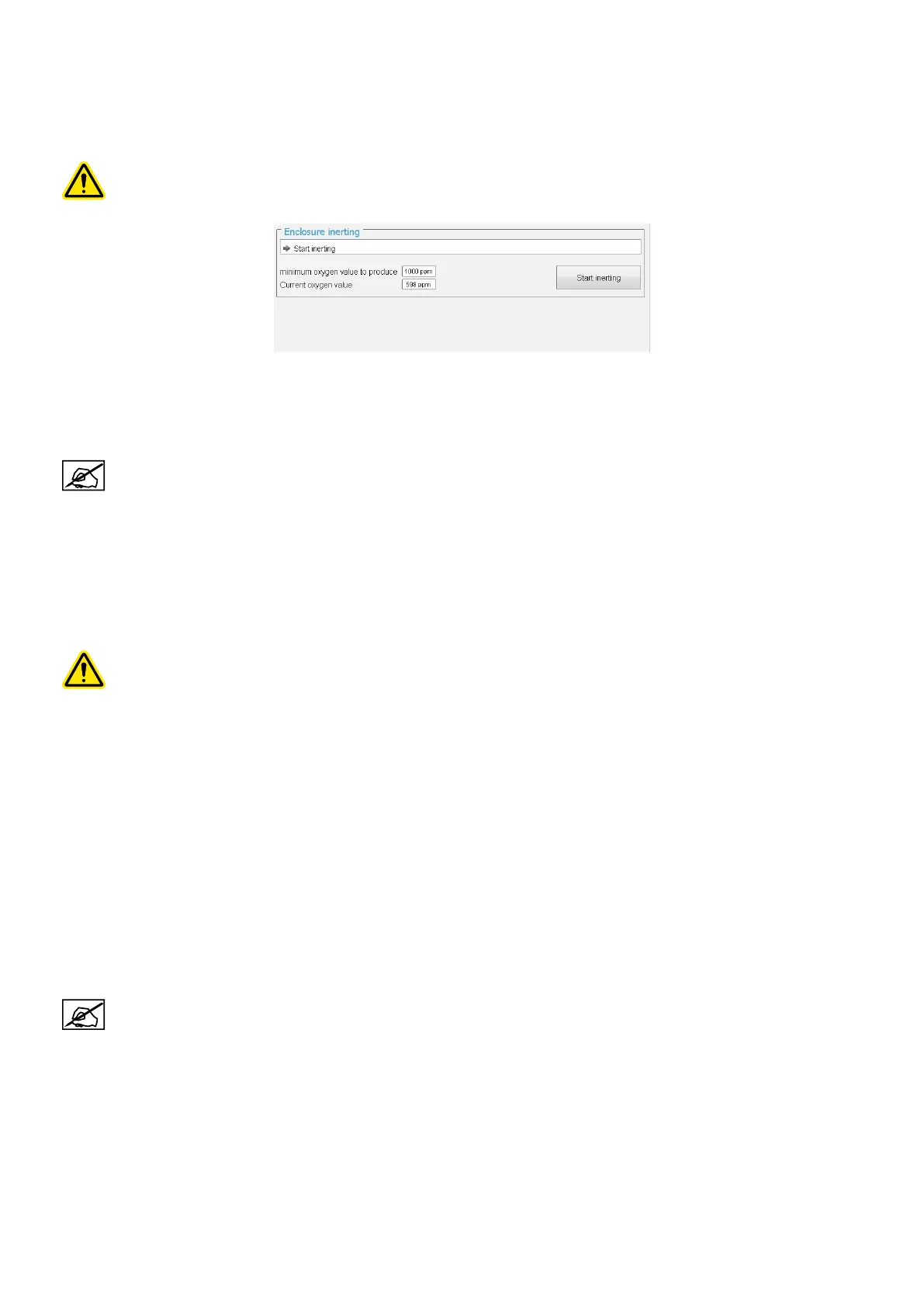

Inerting the manufacturing chamber

The machine needs a gas to create an inert atmosphere in the manufacturing chamber. This cover gas inhibits any potential

rapid combustion of particulate matter during the process.

The inerting is required for oxidizable or ammable materials, and for better build quality.

When launching, the inerting process will automatically perform the 2 following phases in this order :

manufacturing chamber inerting at rst, then external lter vessel inerting. Make sure the lter is well

connected to the printer before starting the inerting process.

To perform the inerting, follow the instructions of the Preparation Assistant "Step 8 : Loading of the manufacturing le and

inerting" on page 45.

The start of manufacturing shall be carried out only when the oxygen level is below the required value.

START A MANUFACTURING PROCESS

WARNING: THE MANUFACTURING CHAMBER AND PROCESS FILTER MUST BE INERTED BEFORE STARTING

ANY JOB. REFER TO SECTION "INERTING THE MANUFACTURING CHAMBER" ON PAGE 63.

Operations described below complement instructions from the "Manufacturing menu" on page 47.

When all the steps of the machine preparation have been completed, the start procedure of a job is as follows:

• Run the sintering of layer #0.

• Run the layering of layer #1. Repeat this operation if the layer obtained is not correct (lack of powder for example).

• Run the sintering of layer #1.

• Run the layering of layer #2. Repeat this operation if the layer obtained is not correct (lack of powder for example).

• Continue step by step as described above, up to layer #5.

• If all ve layers completed successfully on the rst try, then start the full manufacturing in automatic mode.

Make sure that during the rst 10 layers, there is no short feed.

Loading...

Loading...