273D SYSTEMS, INC. PN:80-D27 Rev.B

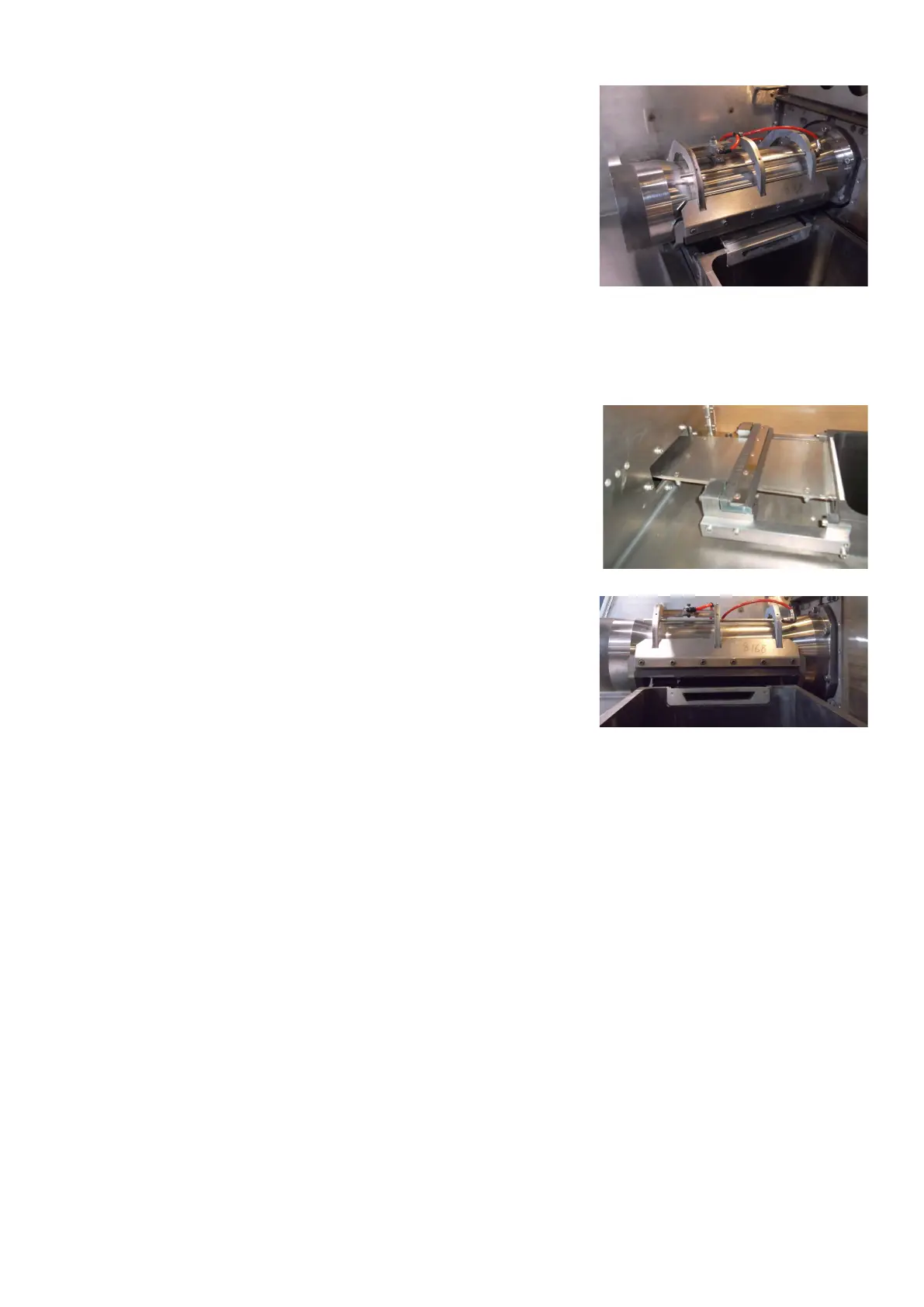

1. Layering module

This module consists of :

• The roller

The roller can move in a straight line using the carriage :

• Maximum position: 970 mm

• Maximum speed: 800 mm/s

• Accuracy: <1 mm

And rotate :

• Maximum speed: 2500°/s (7 turn per second)

• Accuracy: <5°

The combination of different movements of roller and carriage are adjustable for carrying out actions of layering such as

spreading, smoothing and compacting. The layer thickness of powder differs depending on the material properties (particle

size, owability...) and on the desired part characteristics.

• The scraper

Carries powder from the feeding piston to the sintering piston. The scraper

brackets are equipped with a cleaning jet to remove dust from the top of the

roller.

• The roller cleaner

When the appropriate sequence is executed, the roller cleans itself by rotating on

a treated steel blade.

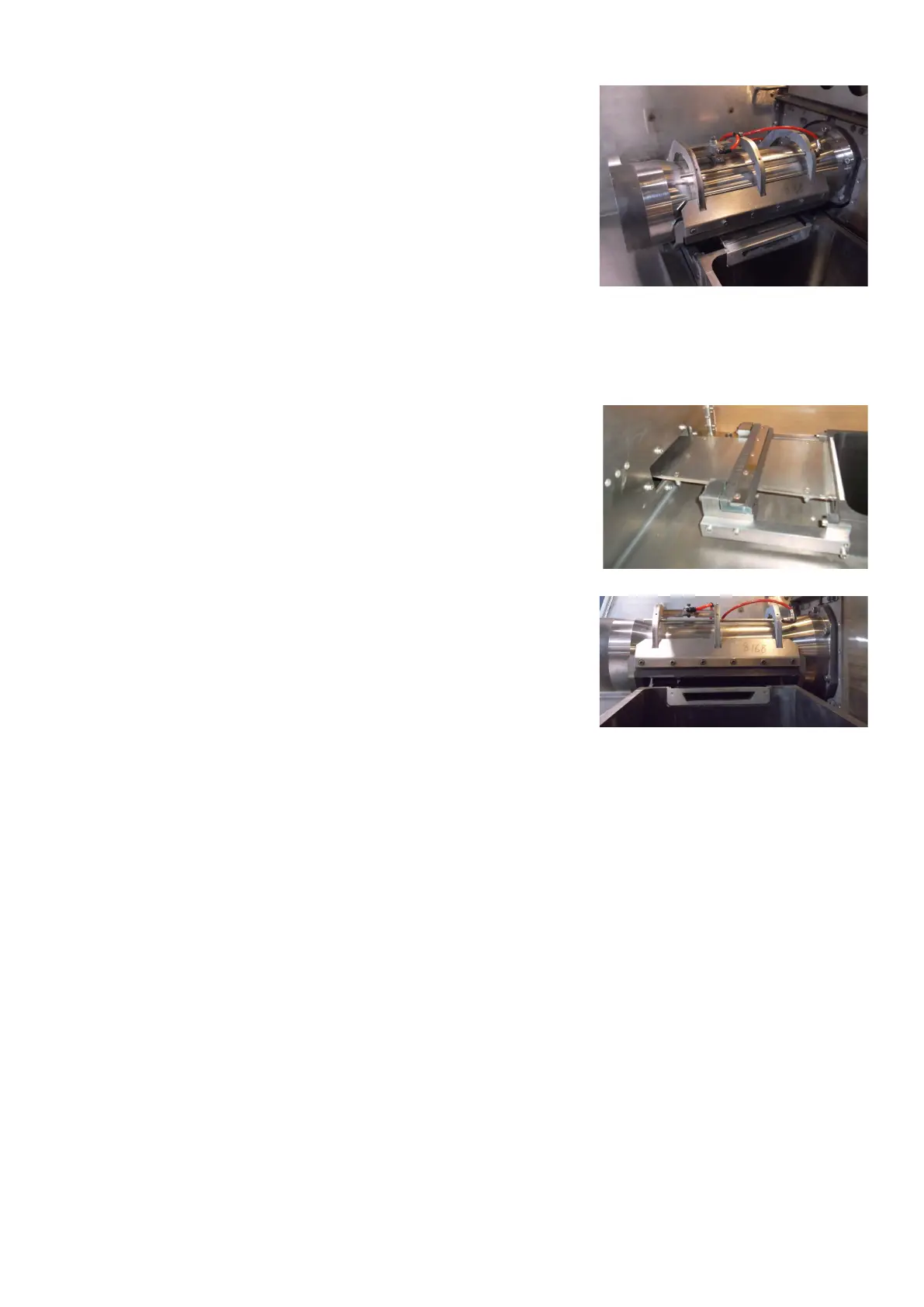

2. Feeding piston

This piston contains the volume of powder that will be used for sintering. Its characteristics are given below:

• Dimensions: 500 x 250 mm

• Powder volume: 50 liters

• Stroke: 400 mm

• Maximum speed: 20 mm/s

• Positioning accuracy: ± 5 µm

• Maximum charge: 500 kg

3. Sintering piston

The parts are manufactured on a sintering plate (positioned on a plate support), located on the sintering piston. Its

characteristics are:

• Dimensions of the sintering plate : 250 x 250 mm with 23.5 mm radius

• Useful stroke: 300 mm (With a sintering plate of 25 mm thick)

• Minimum speed 5 mm/s

• Maximum speed: 15 mm/s

• Positioning accuracy: ±3 µm

4. Collecting tank

It recovers all non-sintered powders and residues of sintering that will be treated in the internal recycling system.

Loading...

Loading...