783D SYSTEMS, INC. PN:80-D27 Rev.B

9. Clean the sides of the manufacturing chamber with the use of a damp cotton cloth to neutralize any presence of the

condensate (black particle aspect).

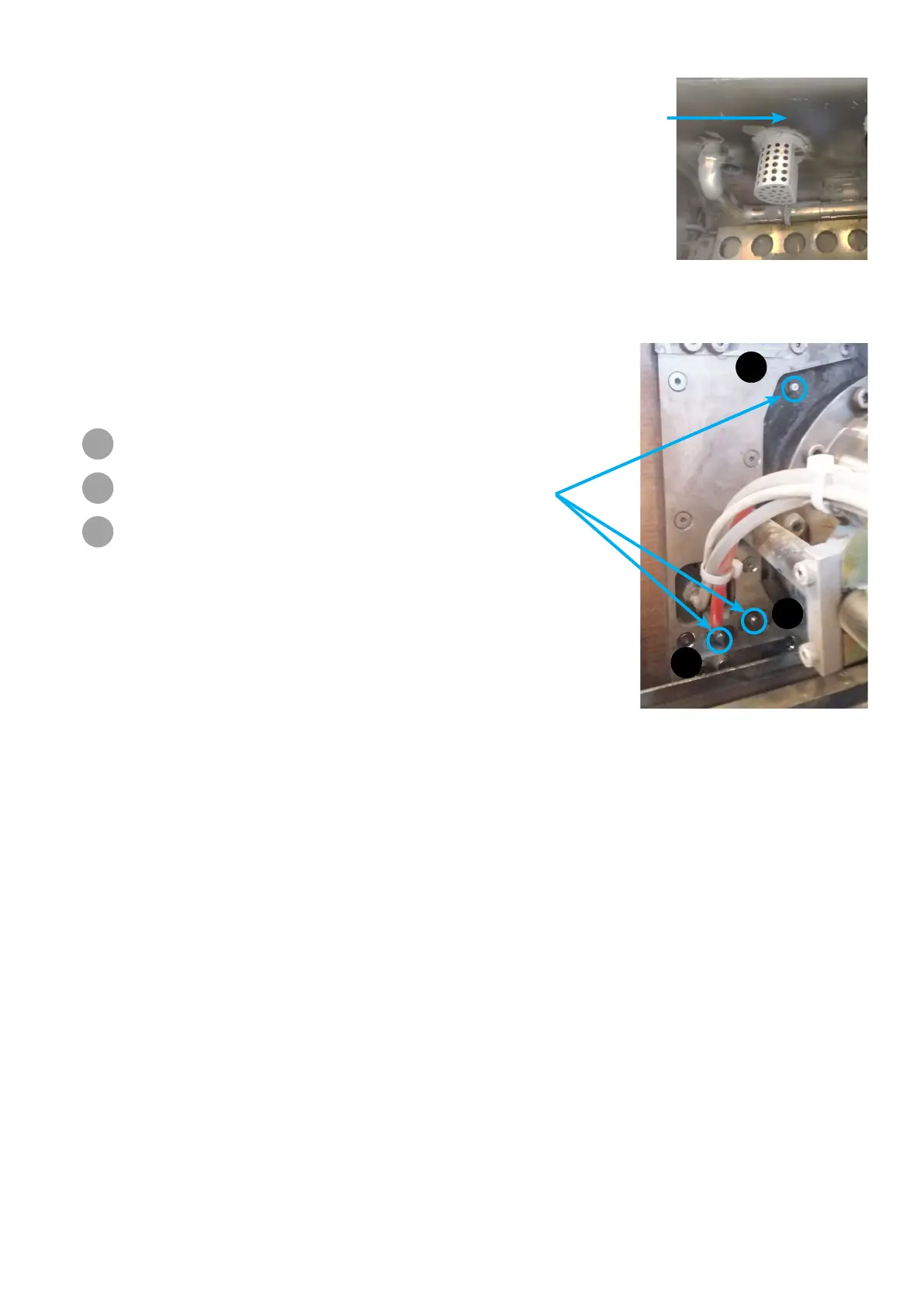

10. Clean the 3 lubrication points on the carriage, as indicated on the gure (A, B and C) with a cotton cloth.

11. Lubricate the elements on these points. Respect the quantity according to the following table :

12. Turn back the crank handle until the manufacturing chamber is fully closed.

13. Ret and tighten the 8 screws of the front door of the main cabinet.

14. Proceed to next procedure (Sieving system cleaning). When the two maintenances complete, make sure to put the

locking key removed previously, and start the printer (see section "Powering up the printer" on page 37).

M6 grease

ttings

Elements lubrication Grease quantity

A

2 x upper ball rails system

+ Nut of ball screw

7 cm

3

B

2 x lower ball rails system 4.4 cm

3

C

Compliance of the ball

screw

3 cm

3

A

B

C

Metal particle

condensate -

Highly combustible

Loading...

Loading...