823D SYSTEMS, INC. PN:80-D27 Rev.B

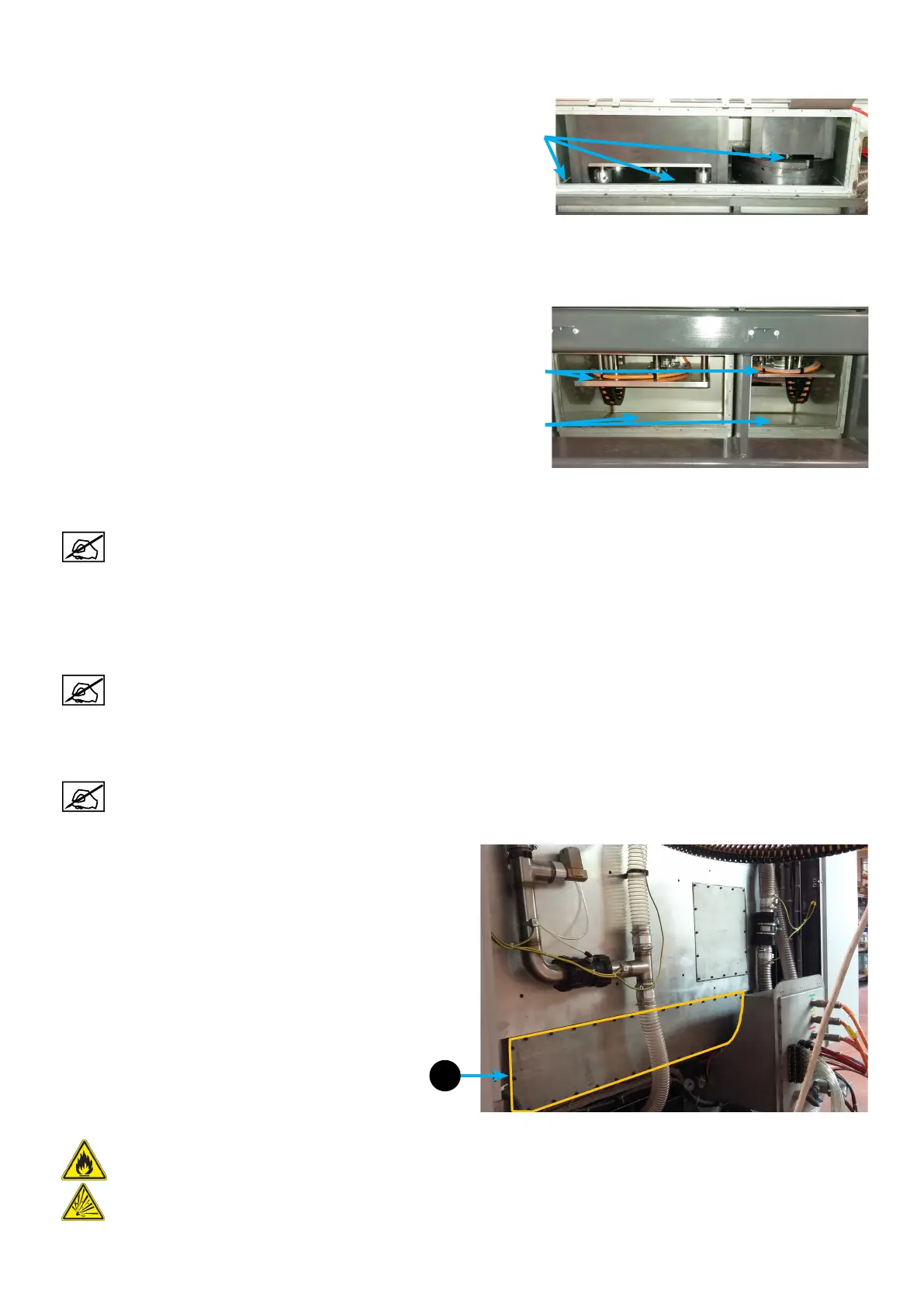

6. Clean the top enclosure : remove any presence of powder with the use of a vacuum cleaner and a natural ber brush.

Depending on the grain size of the material, some powder may be present on the “cleaning area” section, preventing

the printer from operating properly.

7. Finalize the cleaning with a damp cotton cloth.

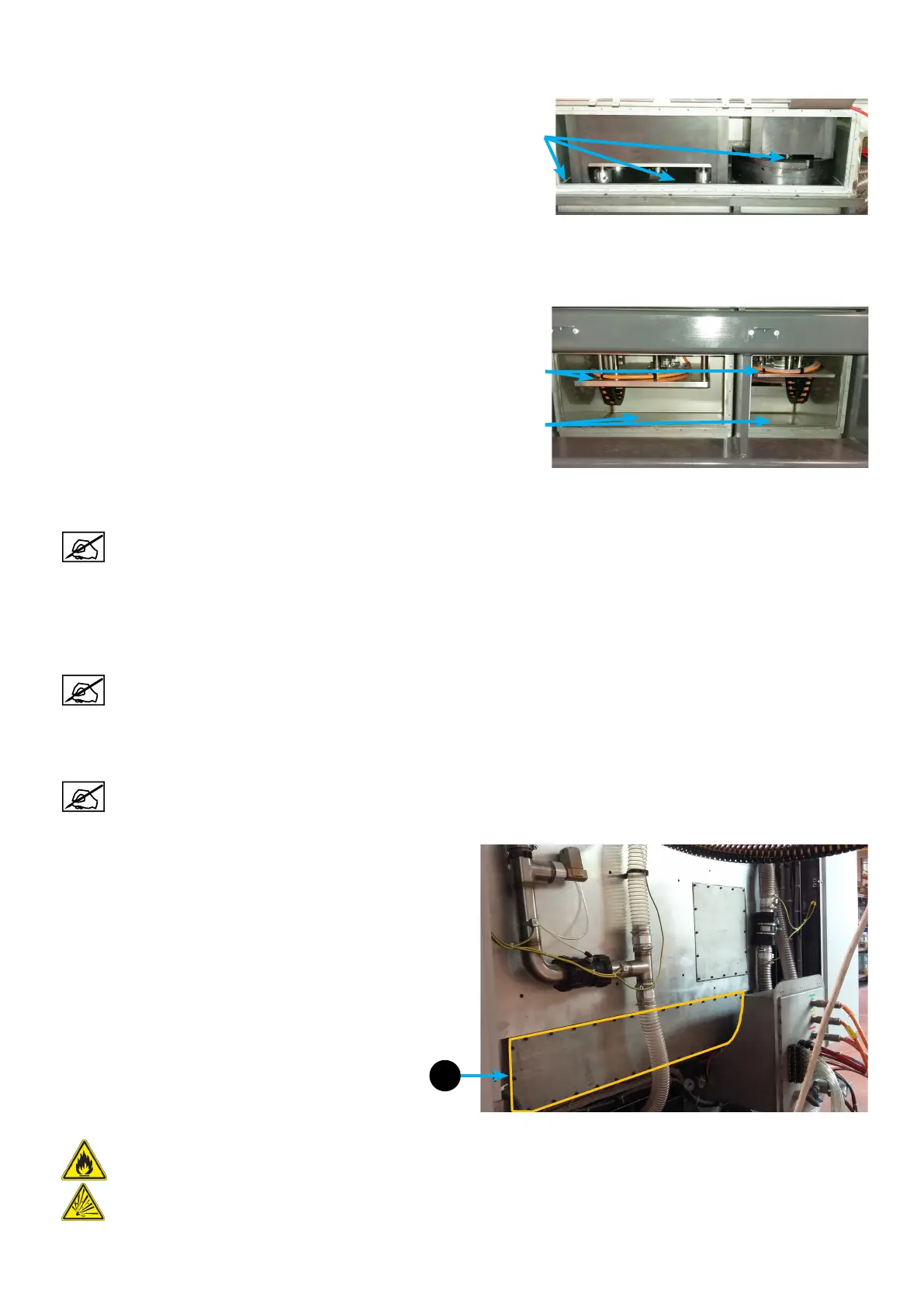

8. Clean the 2 bottom enclosures : remove any presence of powder on the bottom of the enclosures and on the plates,

with the use of a vacuum cleaner and a natural ber brush.

9. Finalize the cleaning with a damp cotton cloth.

On this step, the position of the pistons allows a visual inspection of the motor belts. If you note any

issues, please contact your representative 3DSystems contact.

10. Put back the cover panels and secure them by tightening the screws.

11. Close the bottom access doors opened on step 5.

12. Install the protective guard removed on step 5.

The next steps are performed to clean the back casings.

13. Split-up the supply and control cabinets from the main cabinet (the maintenance requires access to the rear of the main

cabinet).

As the ber laser is still connected to the main cabinet, move the supply cabinet gently. Do not damage

any cables.

14. Remove the cover panel (1) at the rear of the main cabinet, as indicated on the gure.

WARNING: FIRE AND EXPLOSION HAZARDS.

COMBUSTIBLE DUST INSIDE. METAL POWDERS ARE FLAMMABLE AND POTENTIALLY EXPLOSIVE,

ESPECIALLY WHEN DISPERSED IN A CLOUD AND EXPOSED TO AN IGNITION SOURCE SUCH AS HEAT OR

STATIC ELECTRICITY SPARK. OPERATORS AND SERVICE PERSONAL SHOULD AVOID DISTURBING POWDER

MANIPULATE CAREFULLY TO AVOID AS MUCH AS POSSIBLE SUSPENDING OF FINE PARTICLES).

Bottom cleaning areas

Cleaning areas

1

Plate cleaning areas

Loading...

Loading...