Maintenance

88

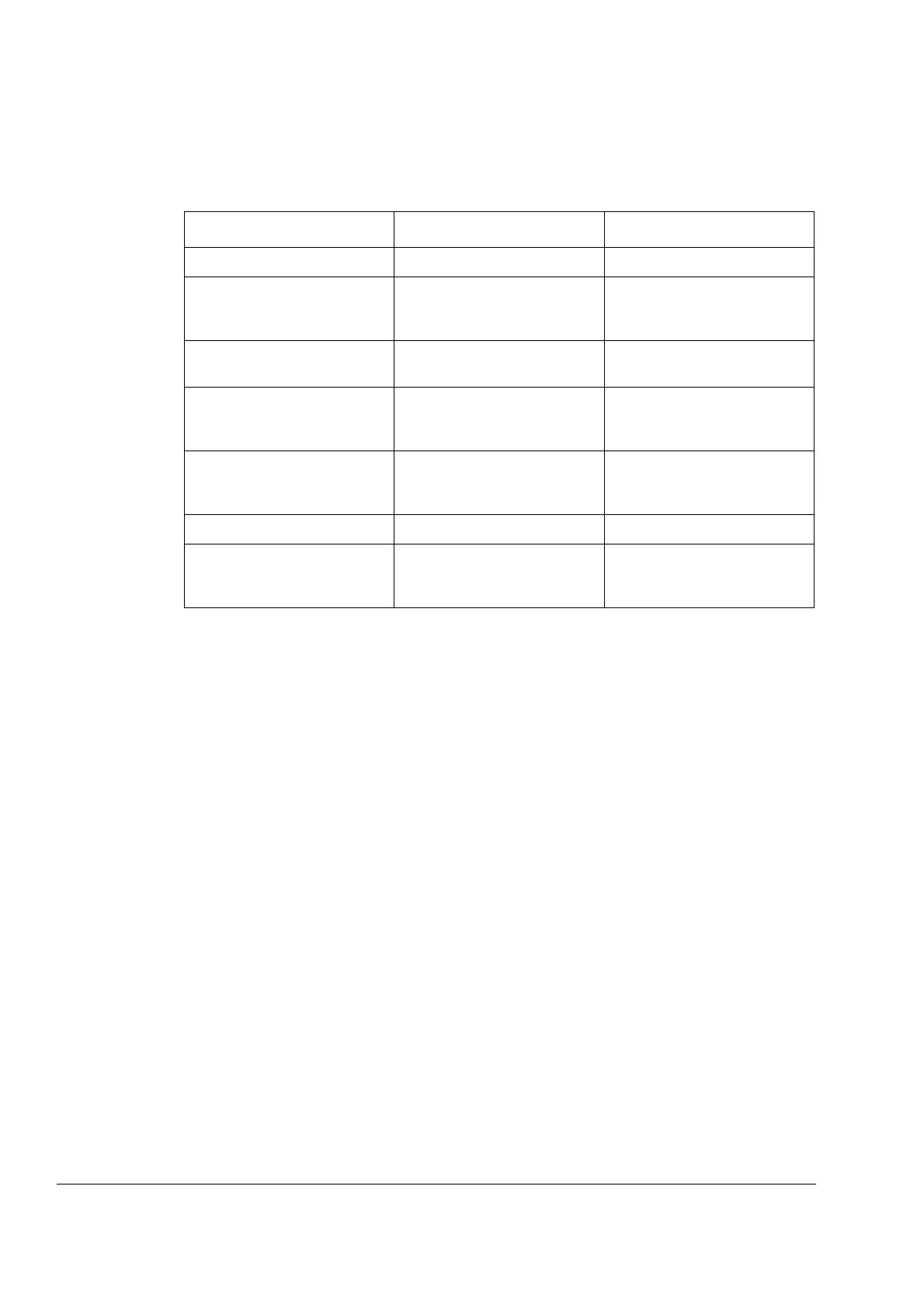

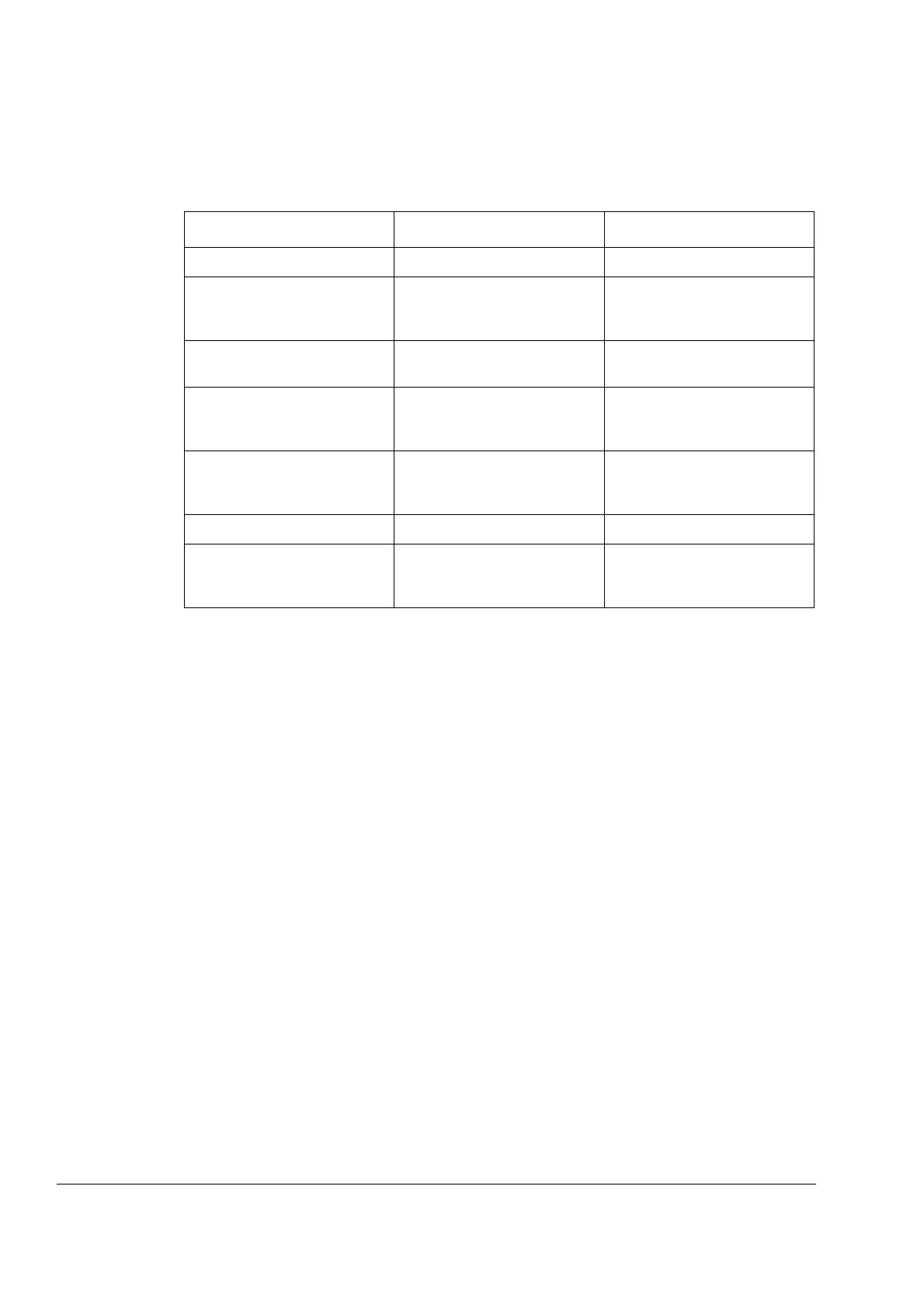

Maintenance intervals

This table lists the routine maintenance intervals recommended by ABB.

Checking and replacing the air filters

Before replacing the air filters of the cabinet, read and repeat the steps in the safety

instructions above.

Heatsinks

Heatsink fins pick up dust from the cooling air. Inverter modules run into

overtemperature warnings and faults if the heatsink is not clean. In a “normal”

environment (not dusty, not clean) the heatsink should be checked annually, in a

dusty environment more often.

Clean the heatsink as follows (when necessary):

1. Remove the cooling fan as described in Cooling fans elsewhere in this chapter.

2. Blow clean, dry compressed air from bottom to top and simultaneously use a

vacuum cleaner at the air outlet to trap the dust. Note: Prevent the dust from

entering adjoining equipment.

3. Refit the cooling fan.

Maintenance Interval Instructions

Capacitor reforming Every year when stored See Capacitor reforming.

Heatsink temperature check

and cleaning

Depending on the dustiness of

the environment, every 6 to 12

months

See Heatsinks.

Cabinet air filter check;

replacement if necessary

Every year

See Checking and replacing

the air filters.

Frame R4i and R5i inverter

modules: Change of

additional cooling fan

Every 3 years See Cooling fans.

Frame R8i inverter modules:

Check and cleaning of power

connections

Every 4 years See Power connections (R8i).

Cooling fan change Every 5 years See Cooling fans.

Frame R4i and larger

inverter modules: capacitor

renewal

Every 10 years See Capacitors.

Loading...

Loading...