336 Configuration

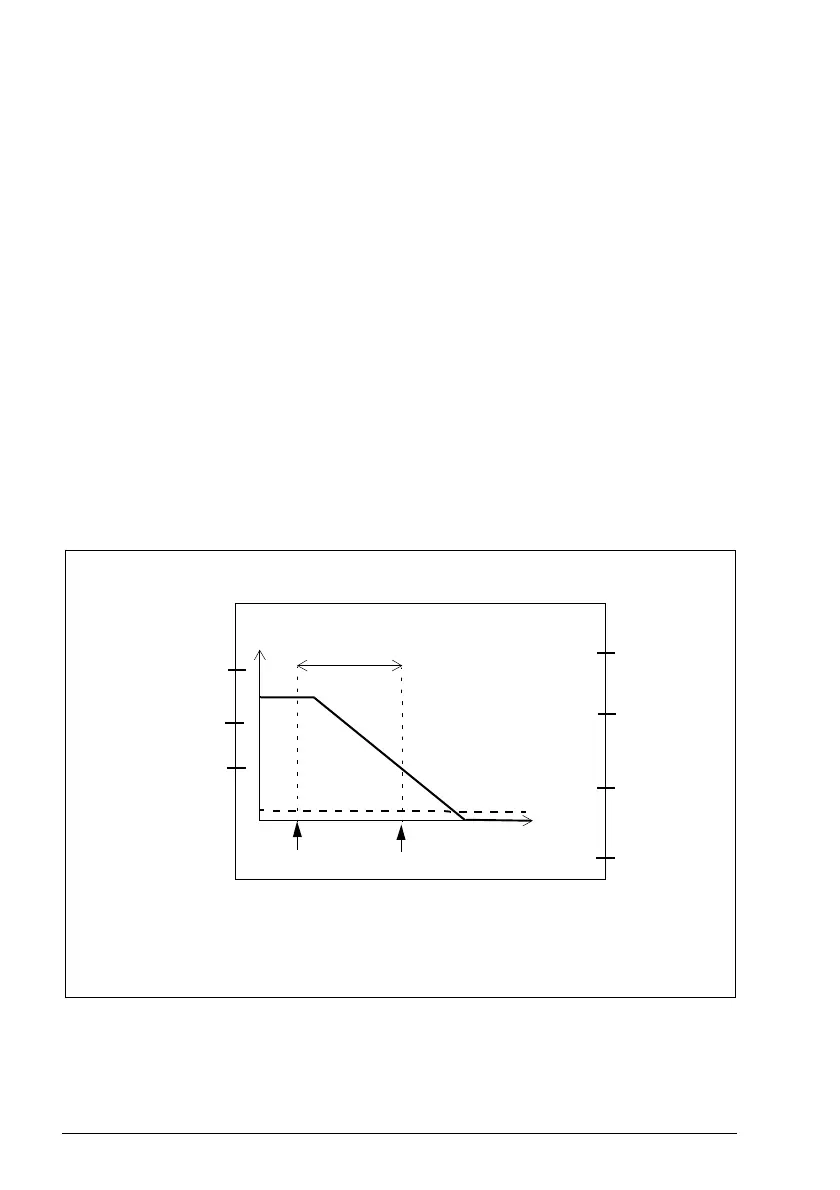

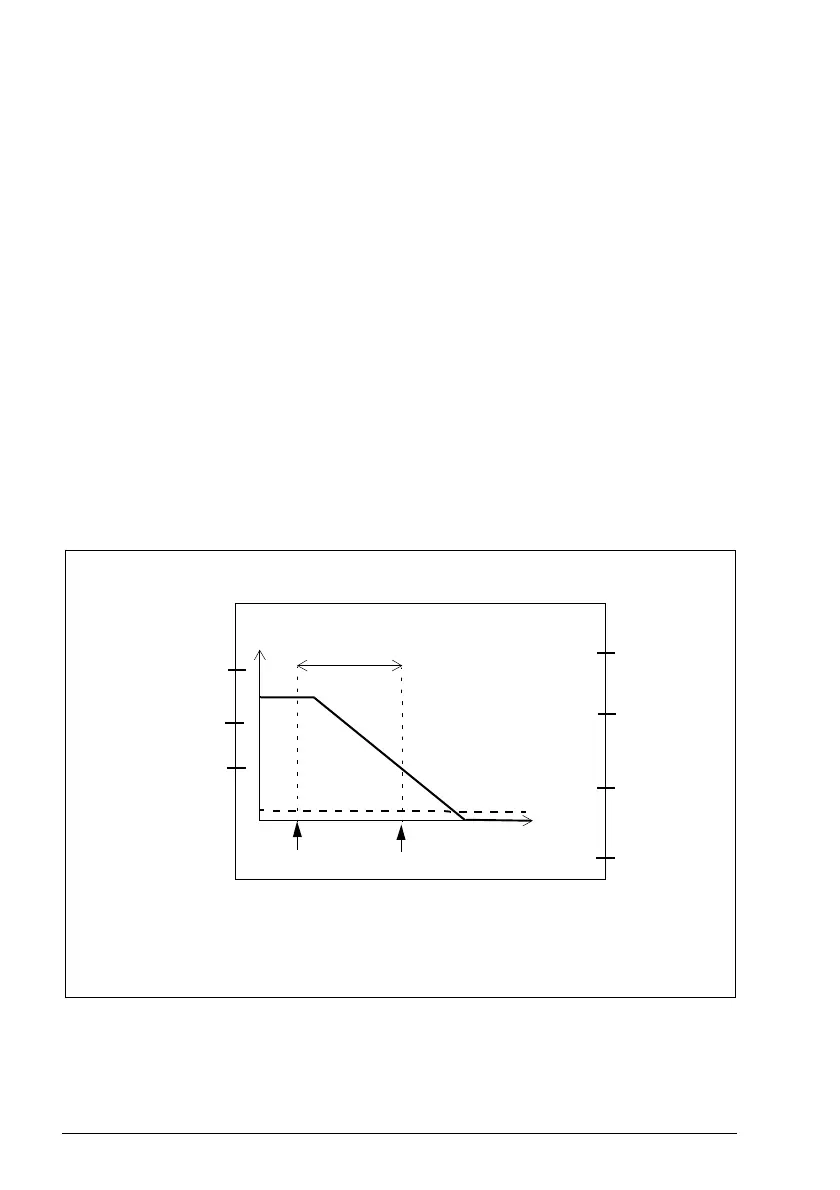

Example 2 (with an encoder): The figure below shows an example of the SBC

before the STO set-up when an encoder is used. Configure the safety encoder

interface first (see section Configuring the safety encoder interface on page 313).

• STO delayed brake with negative delay -500 ms

(SBC.11 STO SBC usage = Delayed brake, SBC.12 STO SBC delay = -500 ms)

• redundant emergency stop button connected to input

(STO.11 STO input A = DI X113:1 & X114:1)

• automatic acknowledgement (STO.02 STO acknowledgement = Automatic)

• zero speed limit where STO function is completed and it can be acknowledged is

40 rpm (parameter FSOGEN.52 Zero speed with encoder = 40 rpm)

• brake connected to redundant output, diagnostic pulses activated

(SBC.21 SBC output = DO X113:7 & X114:7, SAFEIO.53 and SAFEIO.56 = On),

SAFEIO.21 Safety relay 1 output = DO X113:7 & X114:7)

• STO is activated if brake feedback fails (SBC.22 SBC feedback action = STO)

• brake feedback input connected to input

(SAFEIO.22 Safety relay 1 feedback = DI X113:2)

• feedback input type NC (inverted state compared with the brake relay)

(SAFEIO.23 Safety relay 1 feedback type = Mechanically linked NC contacts).

SBC.12 = -500 ms

Speed

Time

STO activated

SBC activated

Inputs

Outputs

STO.02 = Automatic

STO.21

= None

STO.22

= None

SBC.21

= DO X113:7 &

X114:7

SBC.11 = Delayed brake

SBC.22 = STO

SAFEIO.23 = Mechanically linked NC contacts

STO.11

= DI X113:1 & X114:1

STO.12

= None

SAFEIO.53, SAFEIO.56 = On

FSOGEN.52

= 40 rpm

SAFEIO.22

= DI X113:2

SAFEIO.21

= DO X113:7

& X114:7

Loading...

Loading...