Installation 3

Agilent 5517B/BL/C/D/DL/FL User’s Guide 29

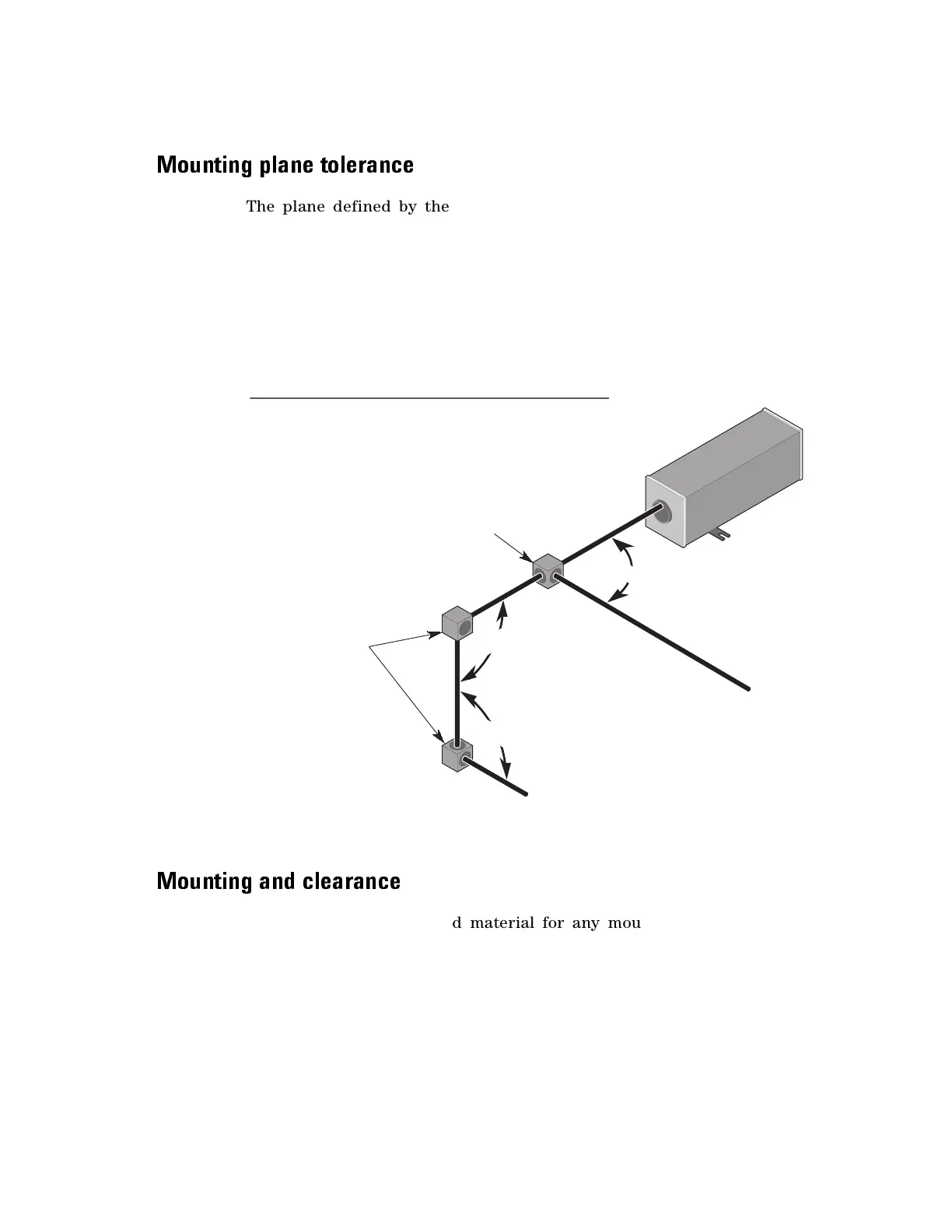

Mounting plane tolerance

The plane defined by the three mounting feet on the laser head must be

parallel to either the bottom or the sides of the beam-splitters and to the

beam-bender housings to within ±3°. It must also be parallel to the bottom

or sides of the interferometers to within ±1°. This ensures the polarization

axes of the interferometers are oriented properly relative to the

polarization vectors of the laser beam (See Figure 9). The laser head can

be rotated in 90° increments about the beam axis (roll) without affecting

the system performance, but the measurement direction sense will change

with each 90° rotation.

Figure 9 Laser position transducer mounting

Mo un tin g an d cle ar a nc e

Aluminum is the preferred material for any mounting surface, since this

will match the thermal coefficient of expansion of the laser base. If

aluminum cannot be used, kinematic mounting of the rear mounting foot is

recommended to minimize stresses due to temperature changes.

Mount the laser head using the three slotted mounting feet that extend

outward from the bottom edges of the unit (depending on the laser head

model you are using, refer to Figure 26 on page 78 or Figure 27 on

page 79 for exact locations and dimensions). The mounting feet may be

90

°

±

3

°

90

°

±

3

°

90°

±

3°

LASER POSITION TRANSDUCER MOUNTING

Beam Splitter

Beam Bender

Loading...

Loading...