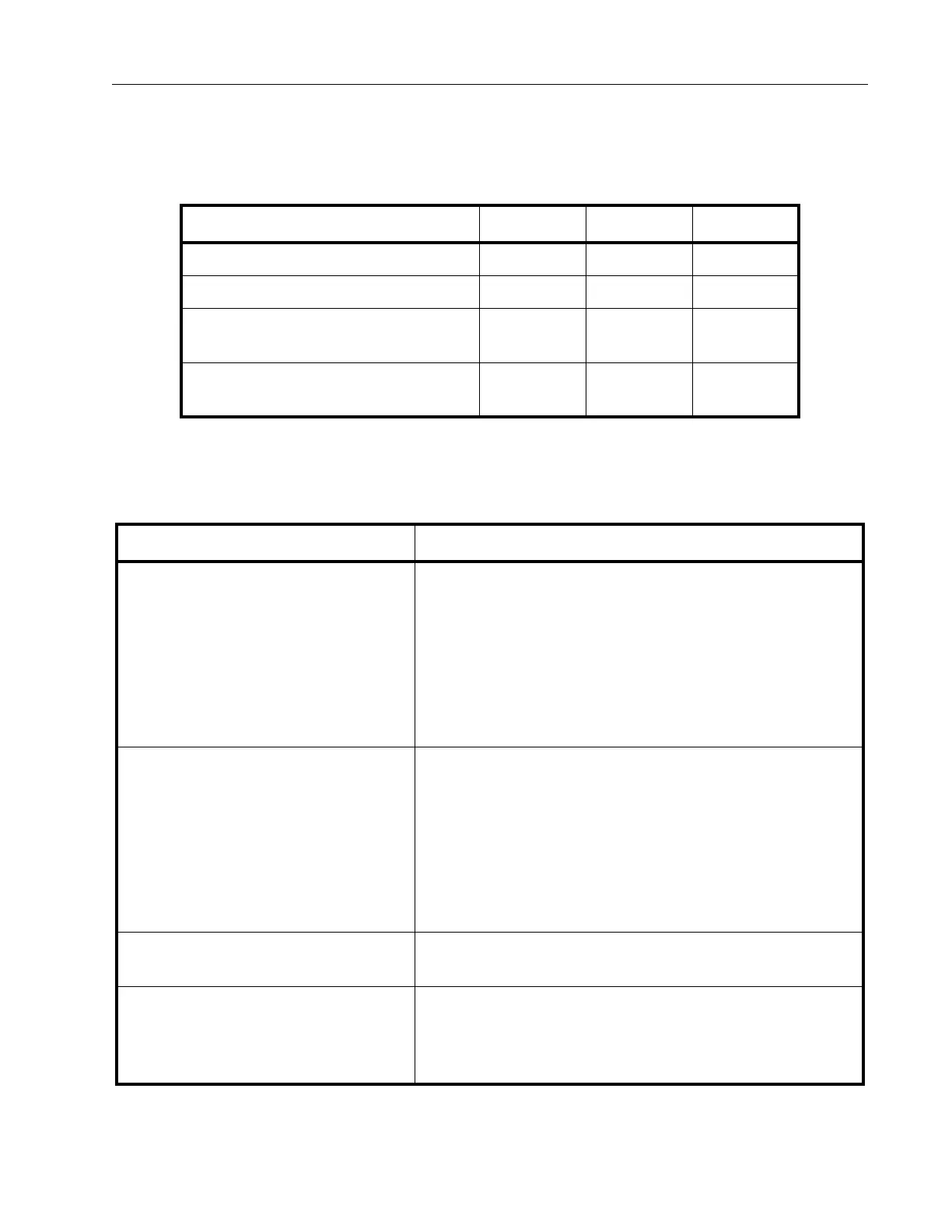

Table 4-1 Scheduled Maintenance

Description Daily 12 Months 24 Months

Calibration check X

Replace the internal calibrated leak X

Replace diaphragm on DP pump (Dry

scroll

pump models only)

X

Replace tip seals on IDP-3 pump

(PD03 on

ly)

X

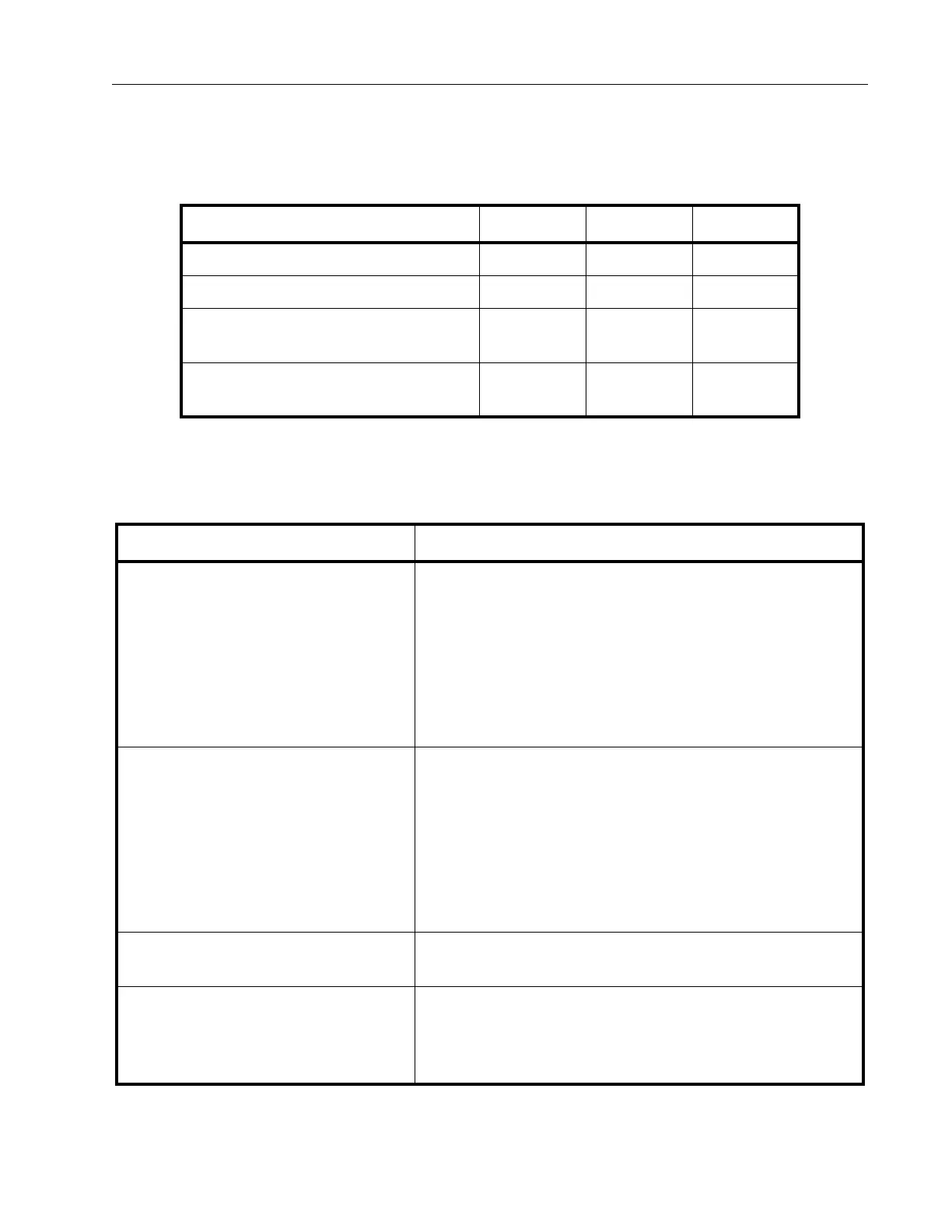

Table 4-2 As-Required Maintenance

Function Most Common Symptom

Spectrometer cleaning The spectrometer is designed to operate for years without

maintenance, however actual performance depends on the

leak detector operational environment. Spectrometer

cleaning restores optimum performance if the unit shows

significant sensitivity loss or high background signal.

Sensitivity loss appears as a high gain value after a

calibration or failure to calibrate with a gain too high error

message.

Filament replacement Filaments are designed to operate for

several years with no

maintenance. When a filament burns out, the system

automatically switches to the other filament and notifies

you to recalibrate. The calibration notice also serves to

inform you of a filament failure. Agilent recommends that

the burned out filament be replaced at a convenient time so

that a spare is always available during leak test operations

to prevent unplanned system down time.

Tuning adju s t m e n ts If calibration is not successful or if the system is calibrated

to an ex

ternal leak, tuning can maximize the helium signal.

Mechanical pump fluid change Persistent, high helium background signal. Fluid

contaminati

on (dirty brown color indicates burnt or

contaminated fluid, milky white consistency indicates high

water vapor content in fluid).

VS Series Helium Mass Spectrometer Leak Detectors

DRAFT 4/23/15

4-3

For simplicity, the maintenance functions in this section are grouped by recommended

frequency, as shown in Table 4-1, based on assumed daily use.

Maintenance functions that may be required on a demand basis, such as changing a

filament after filament failure, are listed in Table 4-2.

Loading...

Loading...