CHAPTER 4: INTRODUCTION TO FEEDBACK MODES AND MONITORING

HF-2500A HIGH FREQUENCY WELD CONTROL

4-4 990-371

If production parts are plated, there can also be a plating process variation over time resulting in

inconsistent welds. These minor material variations are a major cause of process instability, and it is best

welding practice to seek to minimize their effect.

Active Part Conditioner is designed to cope with material contamination, variation and can be

programmed to apply the exact power to the parts required to displace oxide or contaminants. In addition,

the “Part Conditioner” pulse will terminate at a precise current flow preventing the sudden high flow,

which occurs when the oxide is displaced. This prevents weld splash and material expulsion, which occurs

as a result of an excessively fast heating rate. Part conditioning can help to reduce variations in contact

resistance from part to part caused by different fit up of parts. It will stabilize the contact resistances

before the main welding pulse, therefore reducing variation from weld to weld.

How It Works

Both constant current feedback and constant voltage feedback modes are limited in their ability to deal

with varying levels of part contamination and oxide. If constant current feedback were used, the power

supply would ramp the voltage to very high levels in order to achieve current flow through the oxide. This

rapid input of current is likely to cause splash, especially with round parts. Constant voltage mode is not

ideal for this purpose either, as the voltage will be restricted from reaching sufficient levels to break down

the oxide.

Constant power is ideal for this purpose. As the power supply tries to achieve constant power to the

weld, it raises the voltage to high levels early in the output waveform, since current cannot flow due to

the oxide. As the high voltage breaks down the oxide layer, more current flows to the weld and the voltage

and resistance drop. It will achieve this in a controlled fashion to maintain constant power to the weld.

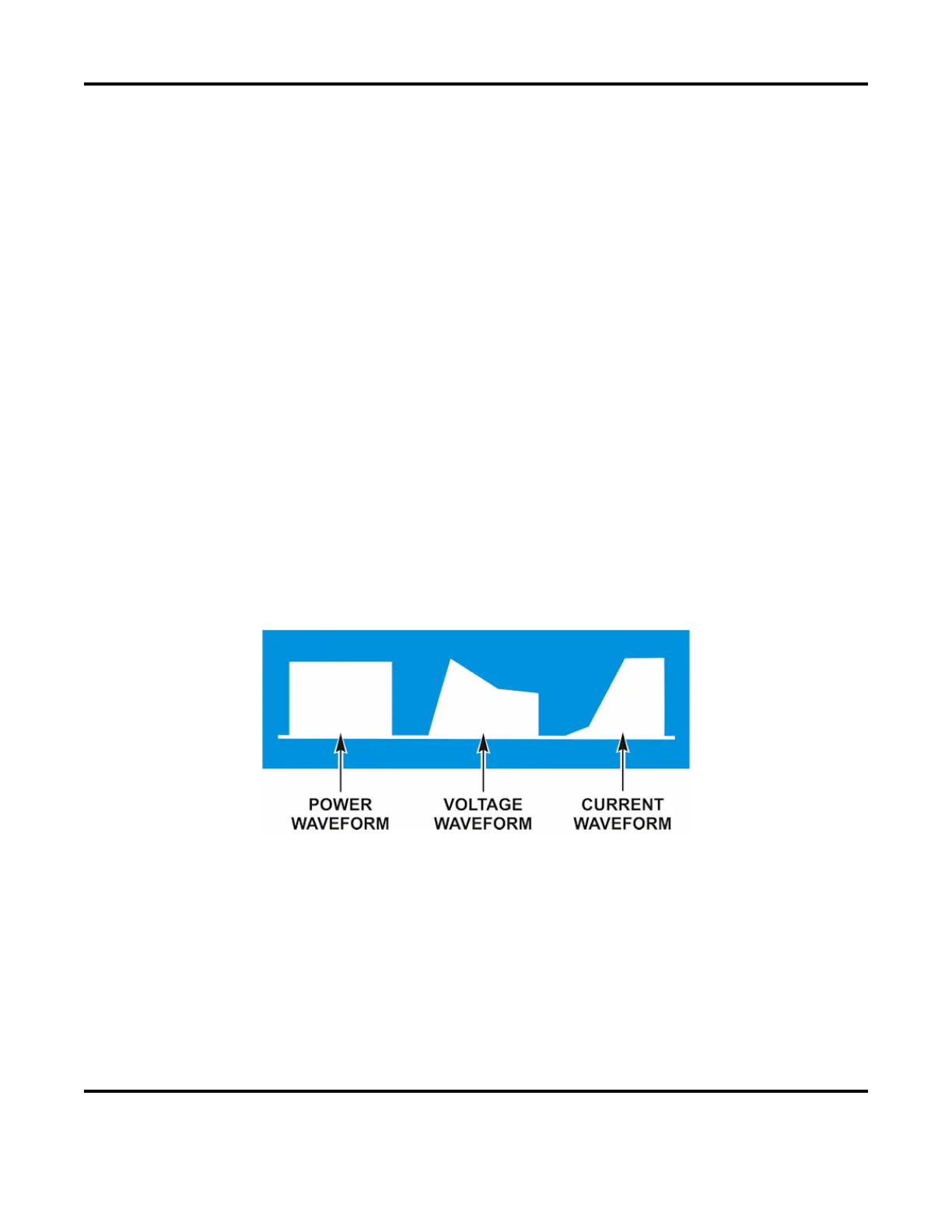

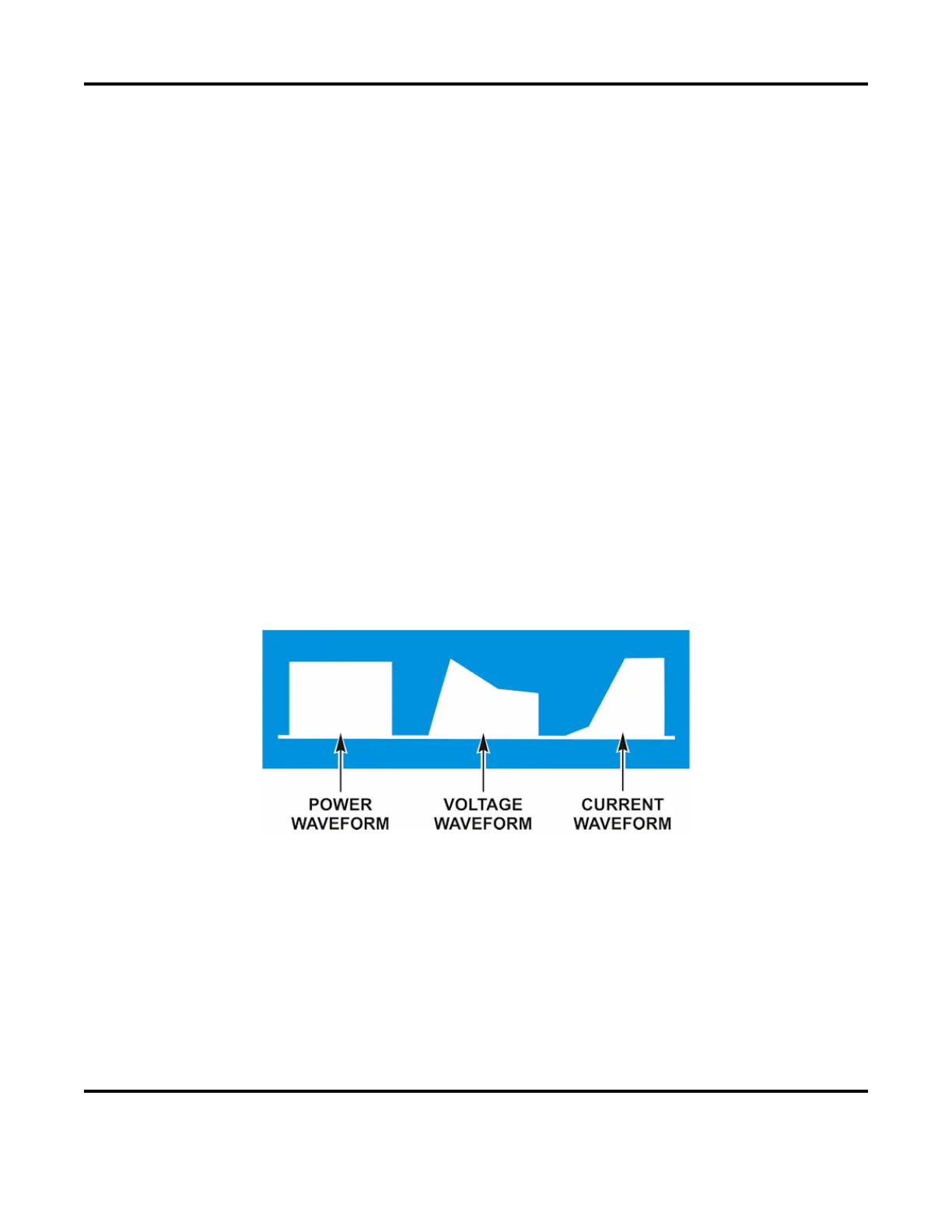

Constant Power Waveform with Corresponding

Voltage and Current Waveforms

Active Part Conditioning uses a dual-pulse output. The first pulse is programmed for constant power,

and the second for either constant current, constant voltage, or constant power. (Constant voltage is

used if there is still a chance of weld splash). The purpose of a dual-pulse operation is to enable the first

pulse to target displacement of oxides and good fit up; the second pulse achieves the weld.

Loading...

Loading...