CHAPTER 4: INTRODUCTION TO FEEDBACK MODES AND MONITORING

HF-2500A HIGH FREQUENCY WELD CONTROL

990-371 4-5

Active Part Conditioning Waveform

The use of a current limit monitor for the first pulse enables the pulse to be terminated when a

predetermined amount of current flow is achieved. The rise of the current waveform is proof positive that

the oxide is breaking down and the parts are fitting up together, ready to weld. The first pulse, therefore,

should be programmed to be much longer than generally required. The power supply will terminate the

pulse based on the reading of current in the power supply’s monitor.

2. Resistance Set

Application

• Reduce variations in Resistance prior to the weld

• Reduce contact resistances before delivering the main weld energy.

Description

Resistance Set is used when parts vary in initial resistance due to:

• Shape and part fit up

• Very small parts

Resistance Set is very similar to APC except that there are applications where you do not want a high

voltage at the beginning of the pulse. Instead, you want to start both voltage and current low and build on

an upslope. This would be used primarily where resistance would vary from weld to weld, coping with

material contamination, and variation due to part fit up problems. It can be programmed to apply the exact

power to the parts required to reduce the resistance to a consistent level for every weld.

Resistance Set uses a dual-pulse output. The first pulse is programmed for upslope power, and the

second for either constant current, constant voltage, or constant power. (Constant voltage is used if

there is still a chance of weld splash). The purpose of a dual-pulse operation is to enable the first pulse to

target variations in resistance; the second pulse achieves the weld.

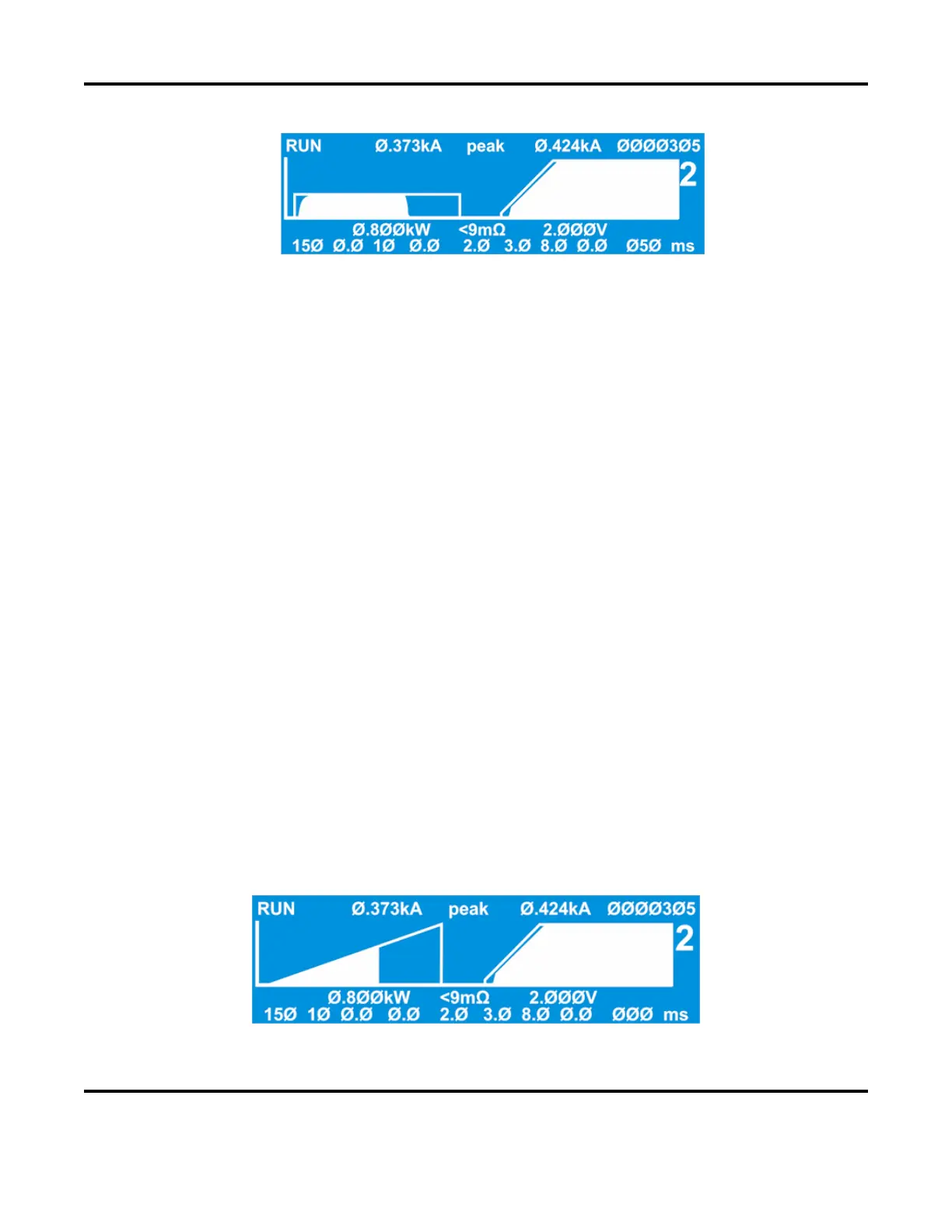

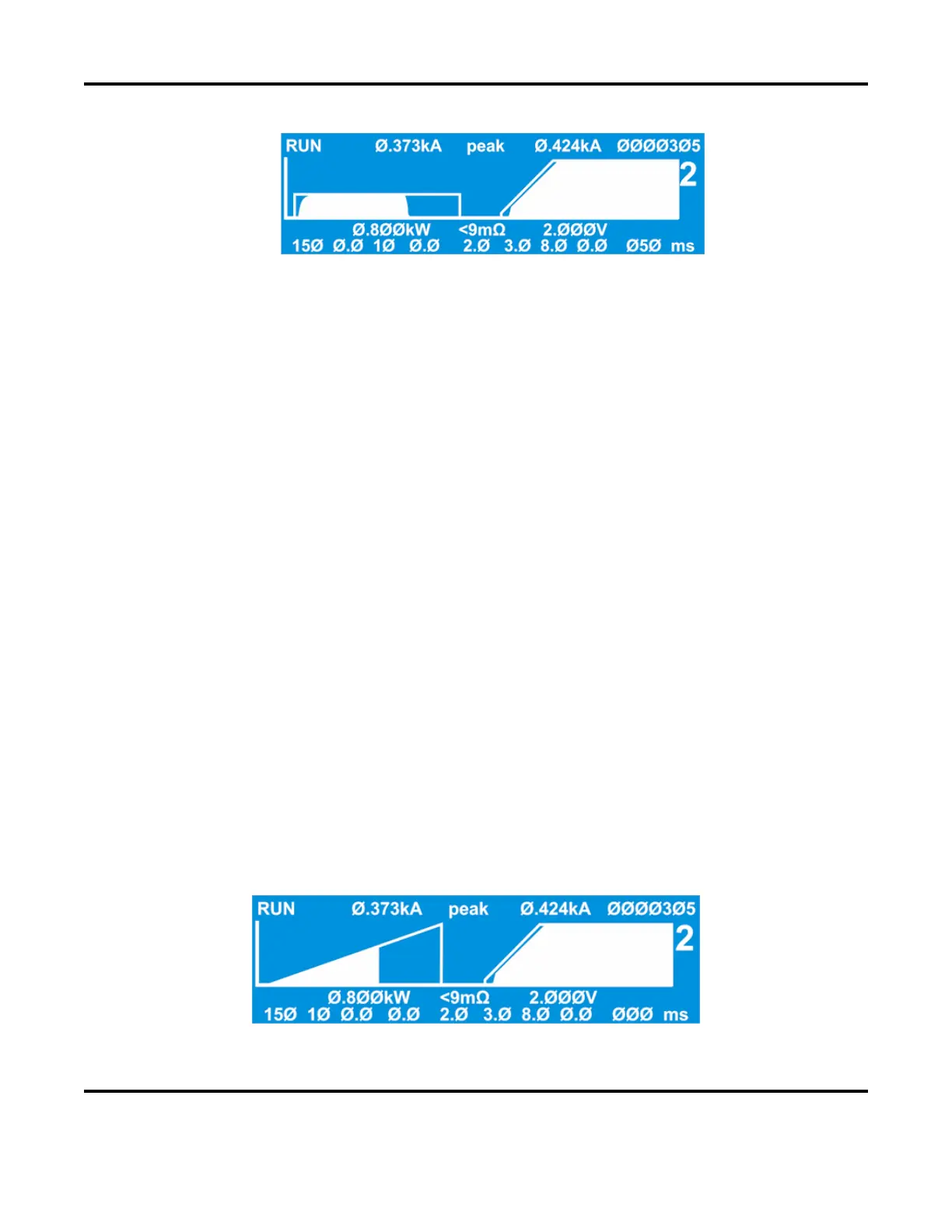

Resistance Set Waveform

Loading...

Loading...