CHAPTER 5. OPERATING INSTRUCTIONS

HF-2500A HIGH FREQUENCY WELD CONTROL

990-371 5-11

PART CONDITIONER (Stop PULSE1)

stops Pulse 1 immediately after upper or lower

energy limits are exceeded, but allows Pulse 2 to fire. This function will not operate

if both pulses are joined without a cool time.

NOTE: See Section IV, Programming For Active Part Conditioning.

r making your selection the display will automatically return to the monitor screen.

Program the upper and lower limits for Pulse 2 by repeating Steps 4 through 6 above using the

keys for Pulse 2, entering appropriate values for Pulse 2.

• The monitor limit mode (current, voltage, power or resistance

different than the monitor limit mode for Pulse 1.

• To “fine tune” the monitor limits to very precise values, see Chapter 4,

Feedback Modes and Monitoring.

HOLD

will bring up the PULSE 2 OUT

OF LIMITS ACTION

screen. This

screen allows you to select the

action that the Power Supply will

take if the Pulse 2 upper or lower

PULSE 2 OUT OF LIMITS ACTION

1. none

2. STOP WELD

NUMBER Select, Page, RUN or MENU

NONE takes no action if upper or lower energy limits are exceeded.

STOP WELD stops PULSE 2 immediately after upper or lower energy limits are

exceeded.

After you have made your selection the

display will automatically return to the

MONITOR

screen.

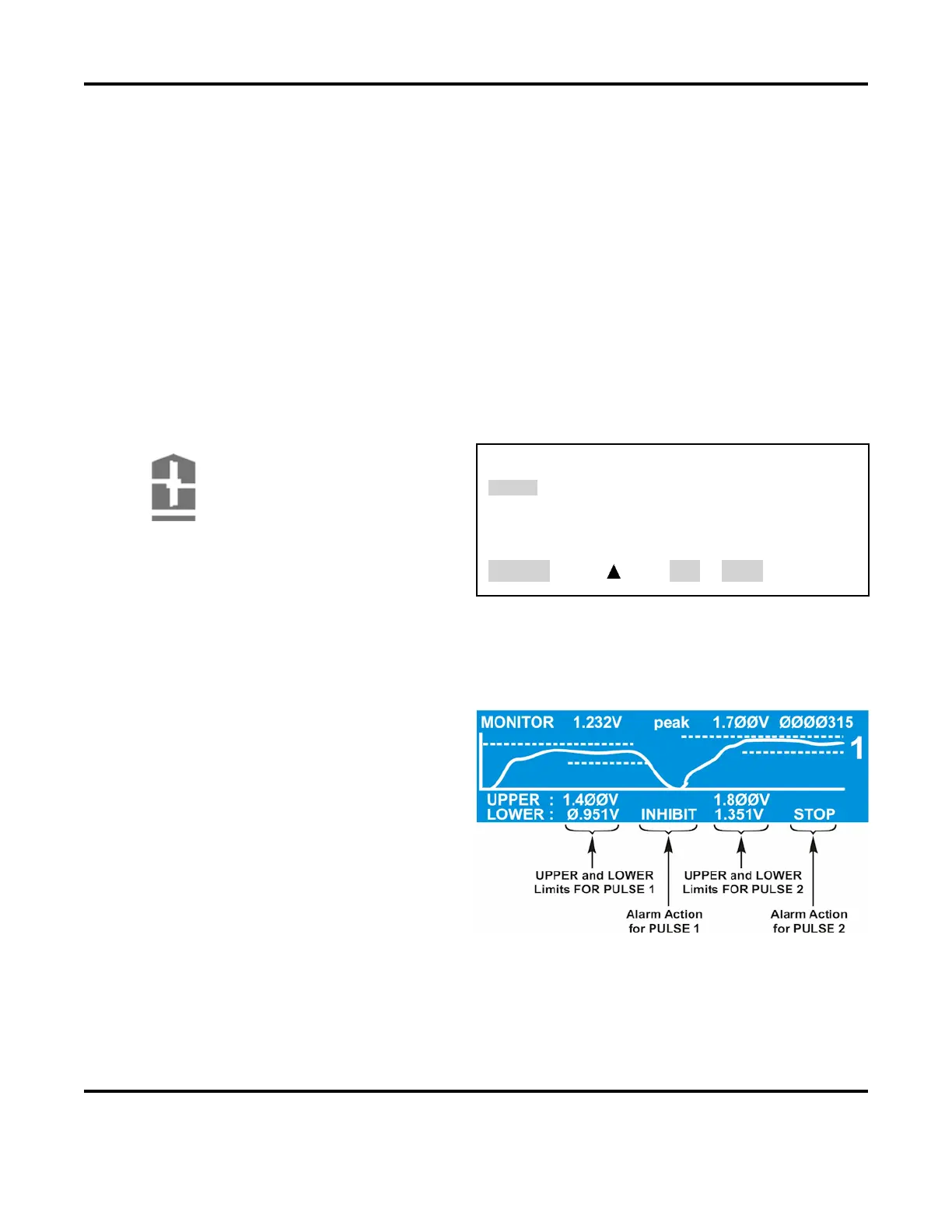

: The Power Supply adds dotted

lines to the appropriate graph to show the

programmed limits

.

The screen on the right shows how the

Limits

and Alarm actions appear when

an actual weld trace is displayed on the

LCD.

After entering or changing monitor limits, you must press either the appropriate

MONITOR

buttons to save the changes. If this is not done, the last input field will remain highlighted,

and the changes will not be saved to memory.

Any welds done in this condition will use the

older, unedited values still stored in the memory.

Loading...

Loading...