APPENDIX A: TECHNICAL SPECIFICATIONS

HF-2500A HIGH FREQUENCY WELD CONTROL

990-371 A-3

Input Signals

NOTE: Except where parenthetically noted below, all input signals accept 5 to 24 VDC, normally open

or normally closed, positive or negative logic. Inputs are optically isolated.

Firing Switch Initiation: 1-level foot switch, 2-level foot switch or opto firing switch.

Remote Control Barrier Strip: Remote weld schedule select, process inhibit, emergency stop

RS-232: Change weld schedules and individual weld parameters.

RS-485: Change weld schedules and individual weld parameters. “Daisy chain” RS-485 input with

RS-485 output from other HF-2500A Power Supplies and host computer.

Voltage: Weld voltage signal for voltage feedback operation (0 to 10 volt peak).

Weld Head: Plug-and-play connector with Firing and Foot switch inputs, Voltage Sense input

and 24VDC Air Valve Driver output.

Output Signals

Monitor: Internal analog voltage signals representing secondary current feedback (0 - 5 VDC),

primary current (0 - 4 VDC), or weld voltage (0 - 5VDC).

Air Valve Driver: 24 VAC, 1 amp; timing controlled by the HF-2500A. No weld over-force

protection.

Alarm Relay: Four programmable mechanical relays: 24 VAC/VDC at 1 amp.

RS-232: Monitor weld parameter data. Download and upload schedules.

RS-485: Monitor weld parameter data. “Daisy chain” RS-485 input with RS-485 output from other

HF-2500A Power Supplies and host computer. Download and upload schedules.

24V_OUT: 24 VDC power supply, polyfused at 1 amp

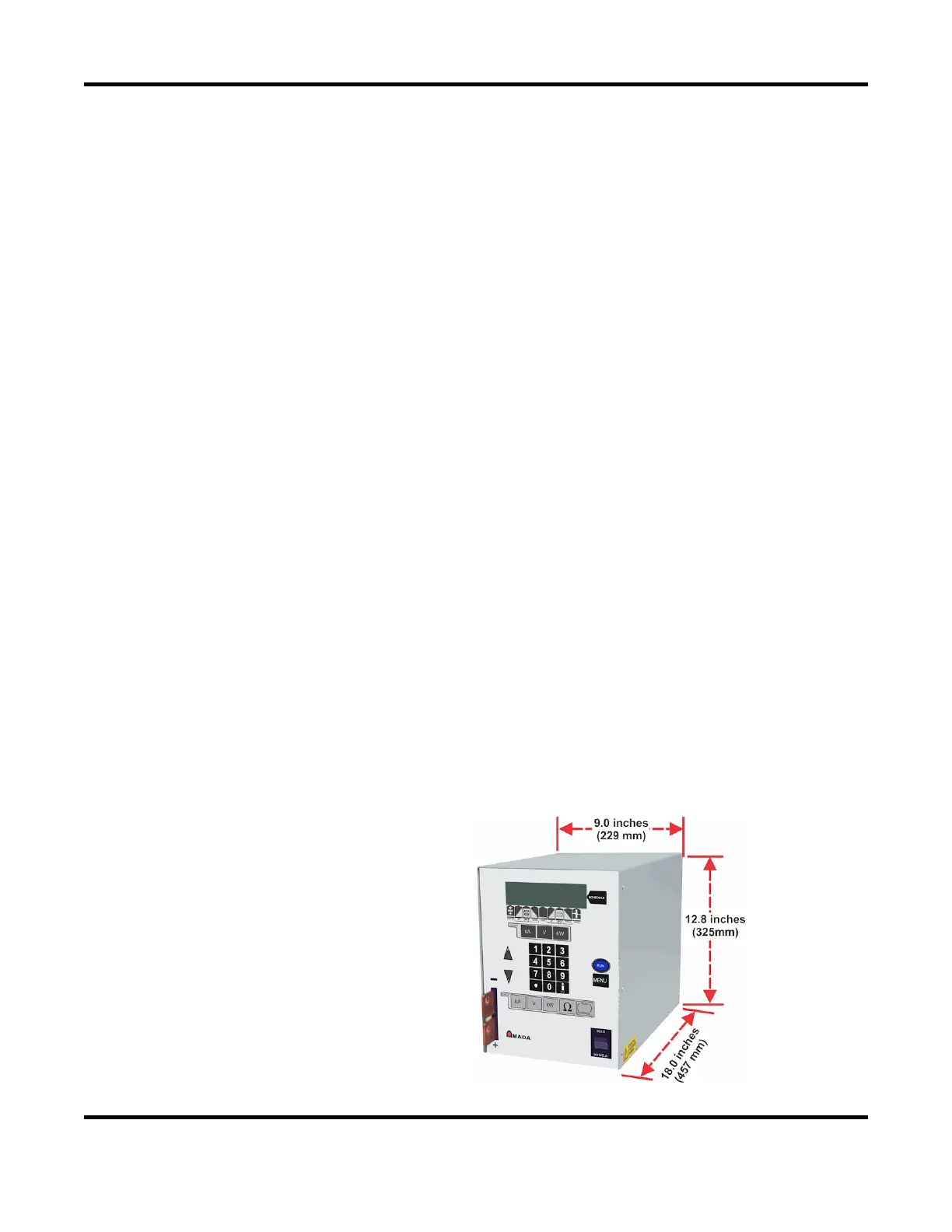

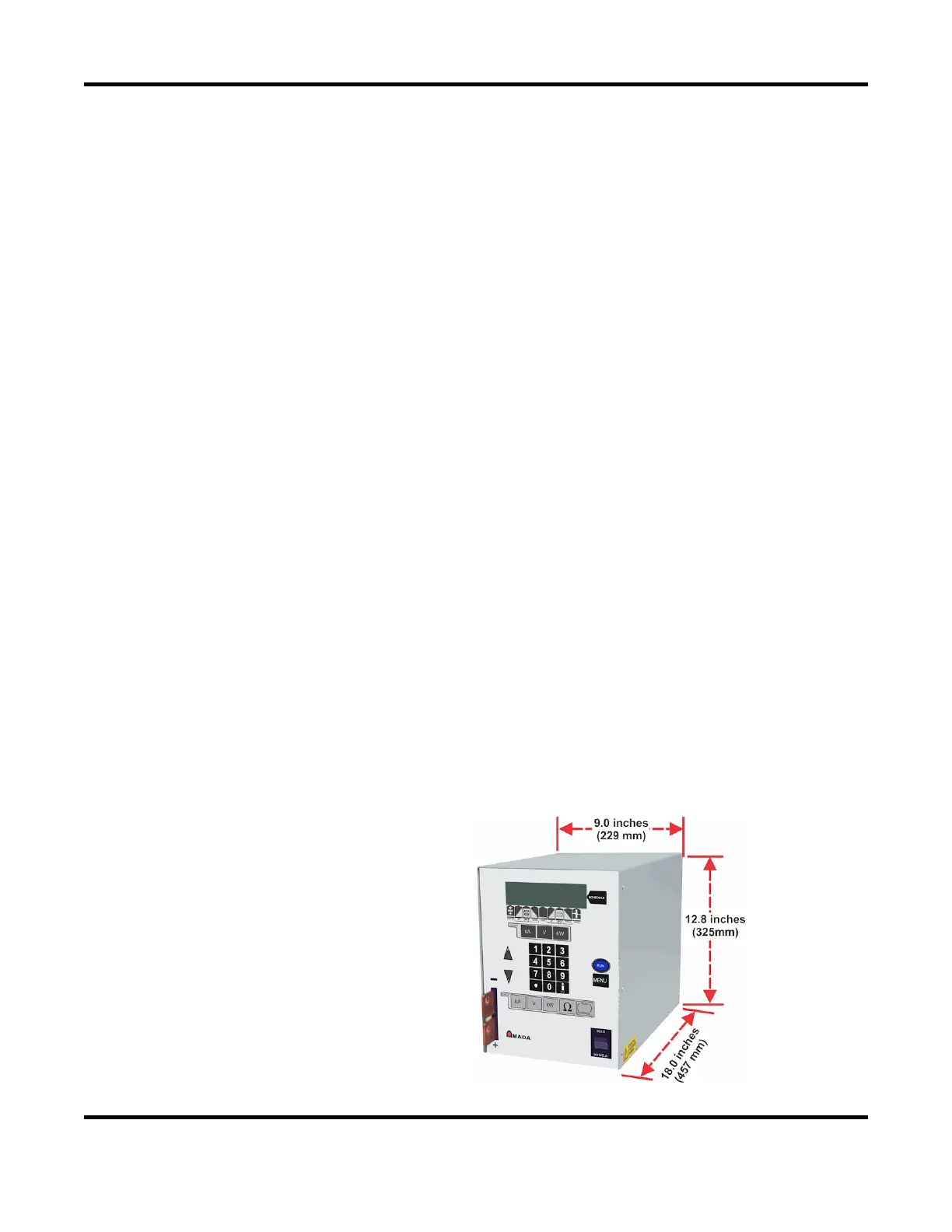

Physical Specifications

Weight: 62 lb. (28 kg)

Loading...

Loading...