32

7.2 Display

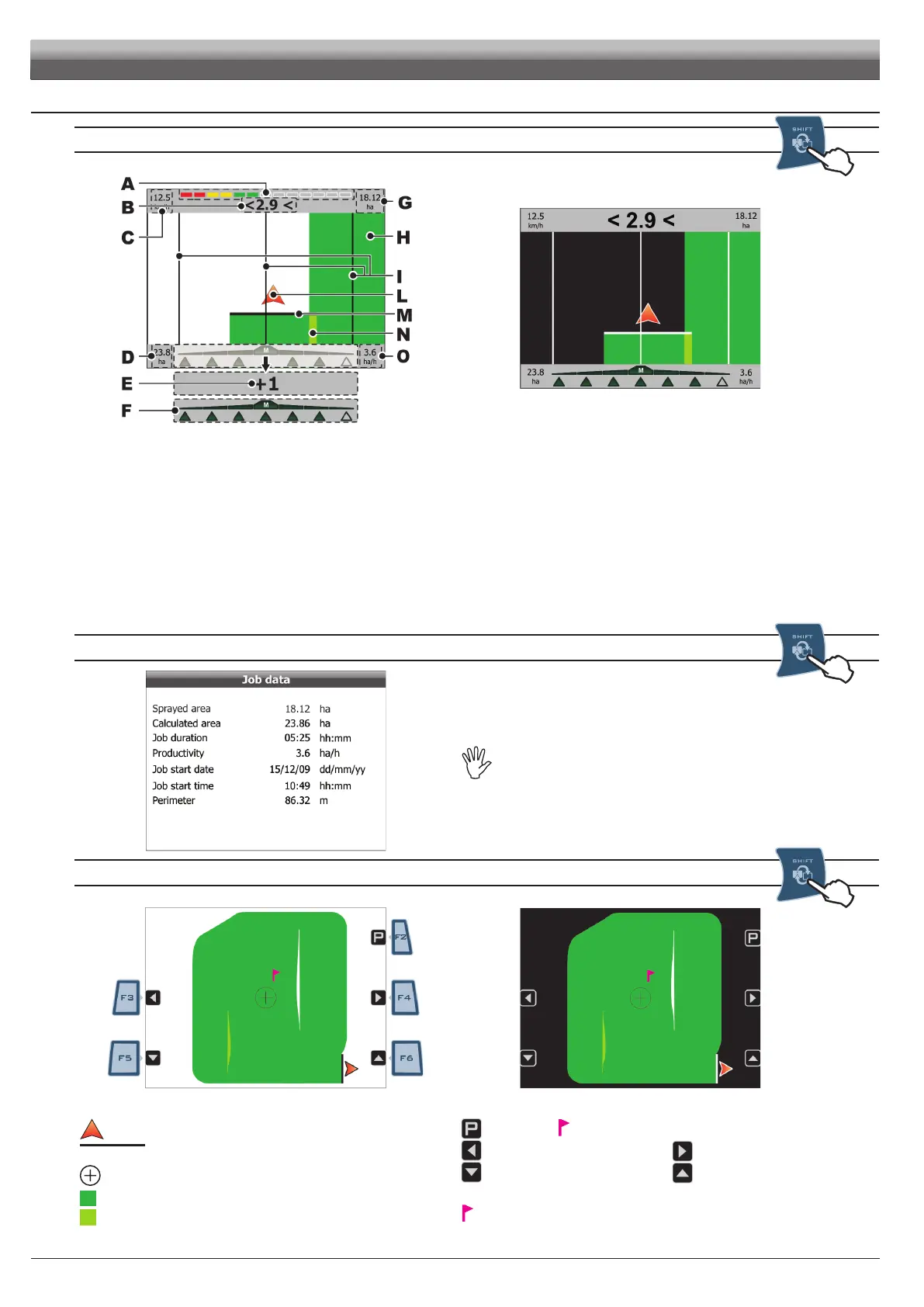

GUIDANCE PAGE

DAY DISPLAY MODE NIGHT DISPLAY MODE

Fig. 94

Fig. 95

A Graphical chart of deviation B.

Every led corresponds to 50 cm.

B Deviation: distance between tractor position and the track to be followed.

C L1 data: spraying job data, customisable by user*

(par. 6.5.4 User preferences - Graphic settings).

D L2 data: spraying job data, customisable by user*

(par. 6.5.4 User preferences - Graphic settings).

E Spray pass number (displayed ONLY IF machine features just one section

valve, par. 6.5.1): the reference line, calculated with the function “Mark AB”, is

number 0, tracks on the left are negative while the ones on the right are positive.

F Boom sections (displayed ONLY IF machine features more than one section

valve, par. 6.5.1): each triangle corresponds to a boom section (par. 7.3)

G R2 data: spraying job data, customisable by user*

(par. 6.5.4 User preferences - Graphic settings).

H Sprayed area

I Reference tracks

L Machine position

M Point where spraying job is performed

N Sprayed areas overlap

O R2 data: spraying job data, customisable by user*

(par. 6.5.4 User preferences - Graphic settings).

* List of spraying job data that can be viewed:

Speed, Applied area, Calculated area, Spraying time, Productivity, Perimeter,

Date, Time, Direction, GPS signal quality, Track number, Available memory.

JOB DATA

Fig. 96

Displayeddataandrelevantunitsofmeasurementarespecied

inpar.10.3.

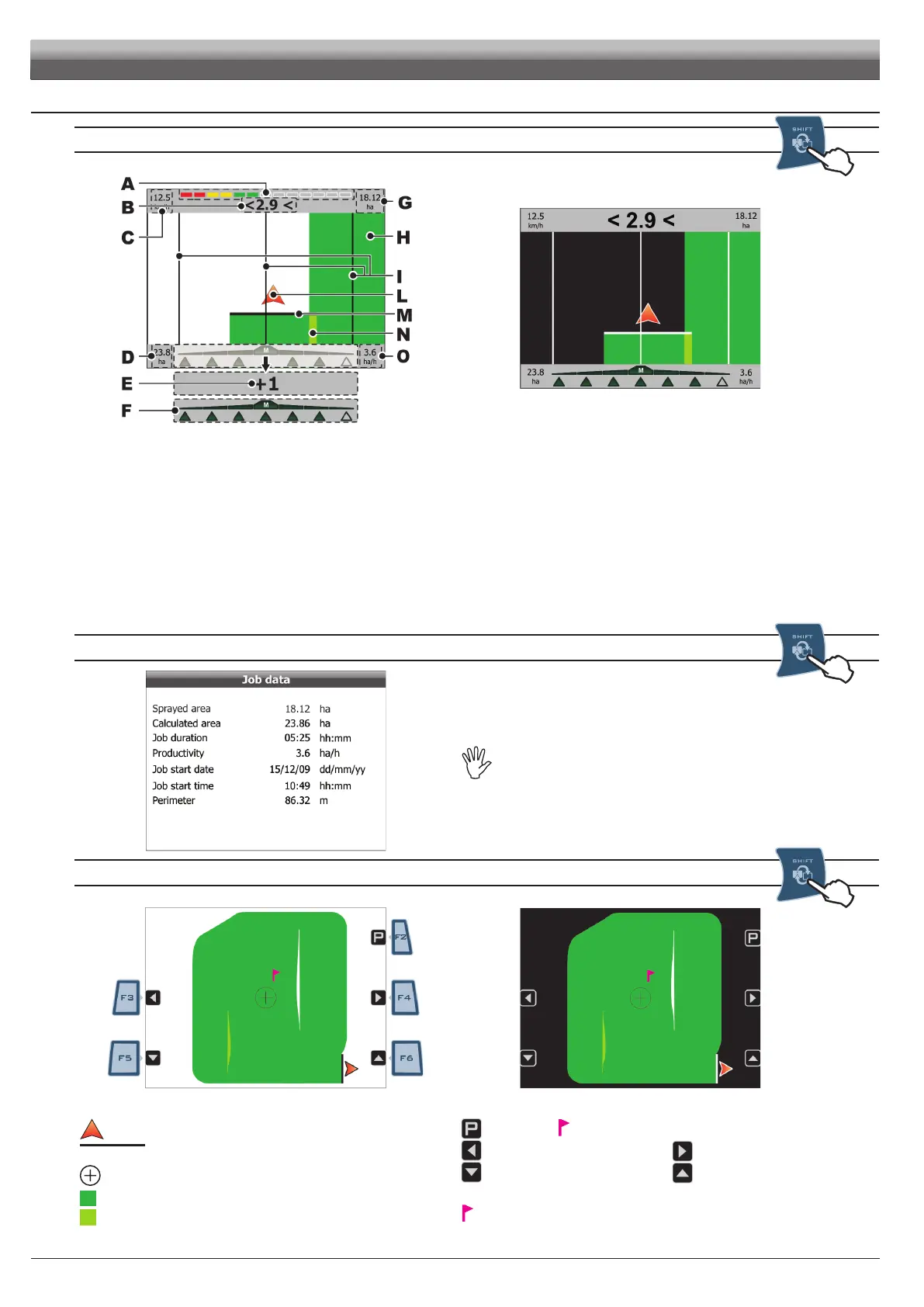

FIELD OVERVIEW

DAY DISPLAY MODE NIGHT DISPLAY MODE

Fig. 97

Fig. 98

Indicators: KeysinFigures97-98

Machine position

Point where spraying job is performed

Cursor

Sprayed area

Sprayed areas overlap

F2 Mark point (break job).

F3 Shift cursor to the left

F5 Shift cursor down

F4 Shift cursor to the right

F6 Shift cursor up

Pointsofinterestmarkedoneld:

Job breaking point, entered using function "Pause" (chapt. 8)

USE

Following

page

Following

page

Back to

guidance

page

Loading...

Loading...