Ch. 6. Fluid Imaging in a Droplet Sec. 6.4. Imaging with the Droplet Holder

4.

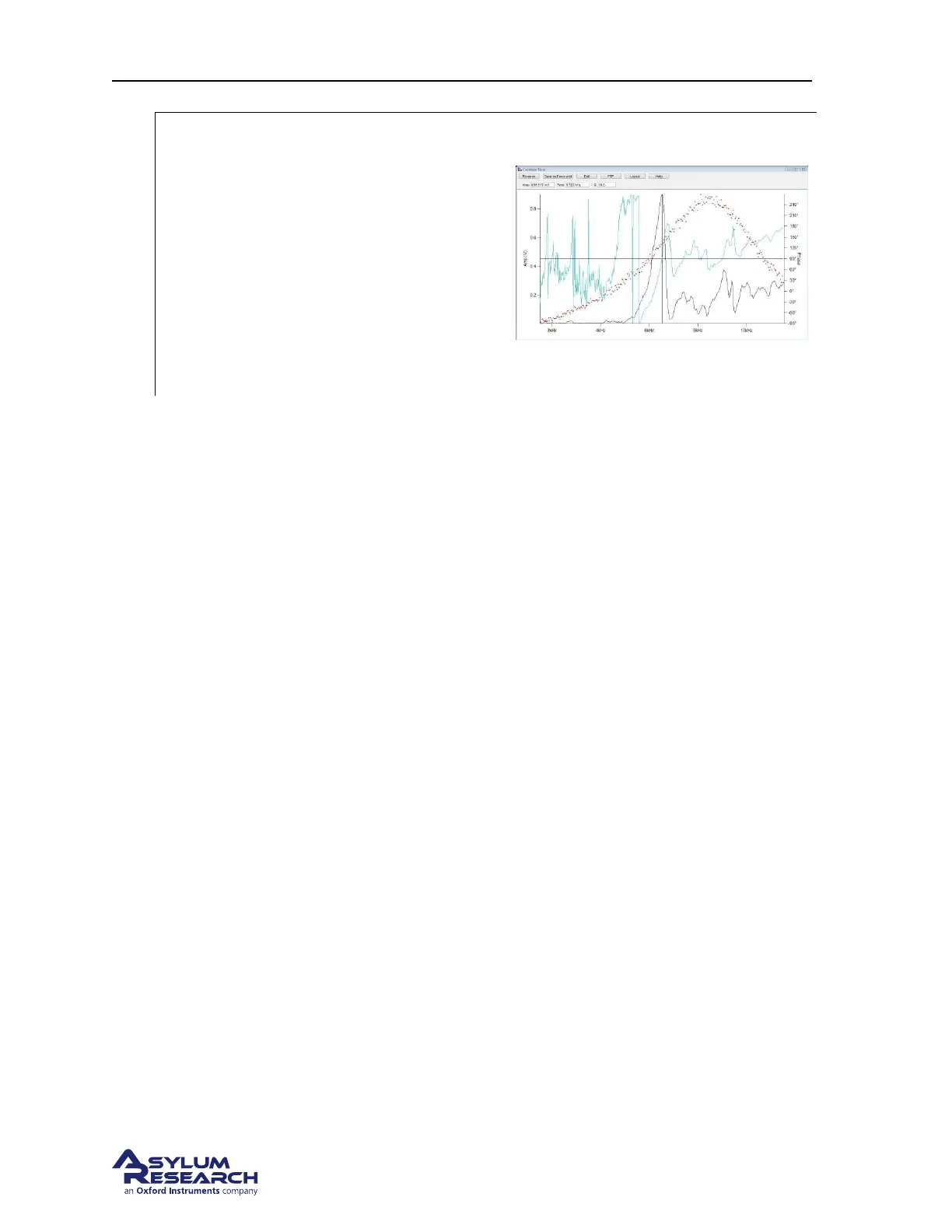

Set the drive frequency and calibrate the

phase signal

• Move the mouse cursor to the apex of

the amplitude peak, right click and

select ’Set Drive Frequency’

• The software will center the pot on the

peak.

• Click on the ’Center Phase’ button in

the tune panel to adjust the phase signal

to the center of it’s range.

5. Click on the ’Stop’ button in the tune panel when the system is tuned.

6.4.2. Imaging Specifics

6.4.2.1. Engaging in fluid in AC mode

As the tip is being lowered to the surface during the engage routine, the Cypher is doing a series of

triggered force curves looking for the free amplitude to equal the setpoint voltage. Once the free am-

plitude is seen as equal to the setpoint voltage, the system stops the approach and is considered to have

found the surface. This works pretty well but in fluid there are several things that can trigger a false

engagement.

• The Feedback Filter - The default frequency response of the feedback filter is 5KHz. Since the

resonance of the cantilever in this example is around 6.5KHz, the instrument is allowed to see

frequencies too close to the oscillating frequency of the lever. This will cause the software to

detect the alternating movement of the cantilever as the amplitude is changing and trigger a false

engagement. Lowering the feedback filter value to around 2KHz will avoid this. Using stiffer

cantilevers with a higher natural resonance will not need this adjustment.

• Hydrodynamic drag - The abrupt drop in the cantilever holder pillar during a motor step can

cause a jump in the deflection signal. This is caused by the drag of the liquid bending a low

spring constant cantilever. Lowering the Feedback Filter to around 2KHz will help reduce this

effect. Stiffer cantilevers will not show this problem.

• The amplitude changes due to the peak shifting frequency - As the probe is lowered to the surface,

the amount of liquid between the glass in the droplet holder and the sample surface can change

the coupling of the drive signal into the cantilever. This may excite the cantilever at a different

frequency so a previously tuned cantilever may not be in tune anymore. If the instrument trig-

gers an engagement, you may want to go back to the tune panel and do a single tune to see the

amplitude response and re-tune if necessary.

Check for a real tip engage by clicking on the ’Engage’ button in the Sum and Deflection meter panel.

Reduce the setpoint voltage in the master controls panel and watch the behavior of the Z control voltage.

If by lowering the setpoint voltage you see the Z voltage move all the way to 150volts then the system

BETA

Page 67

Loading...

Loading...