Ch. 7. iDrive Imaging Sec. 7.2. Cleaning and Repair

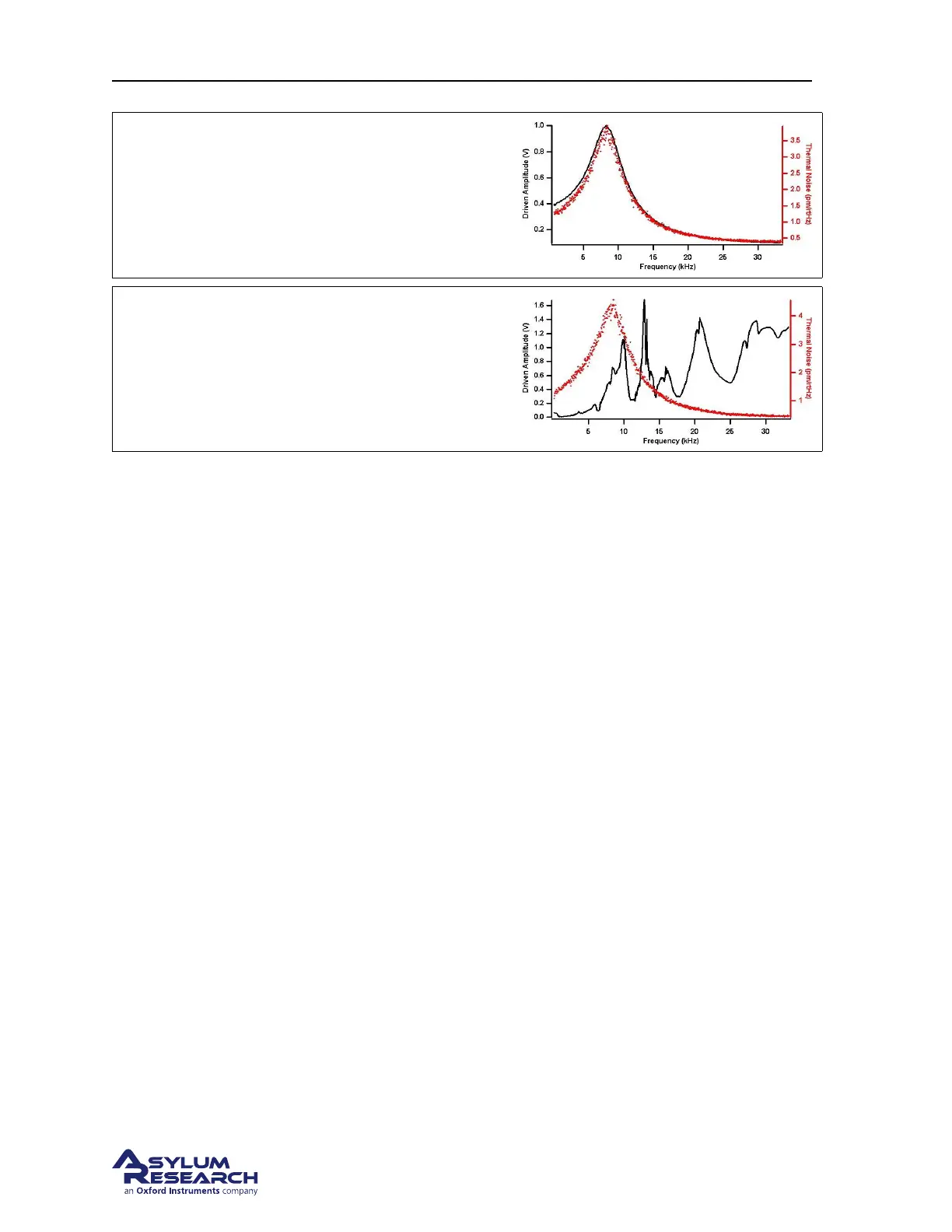

Figure iDrive Tune

Here is an example of a magnetically driven

iDrive cantilever

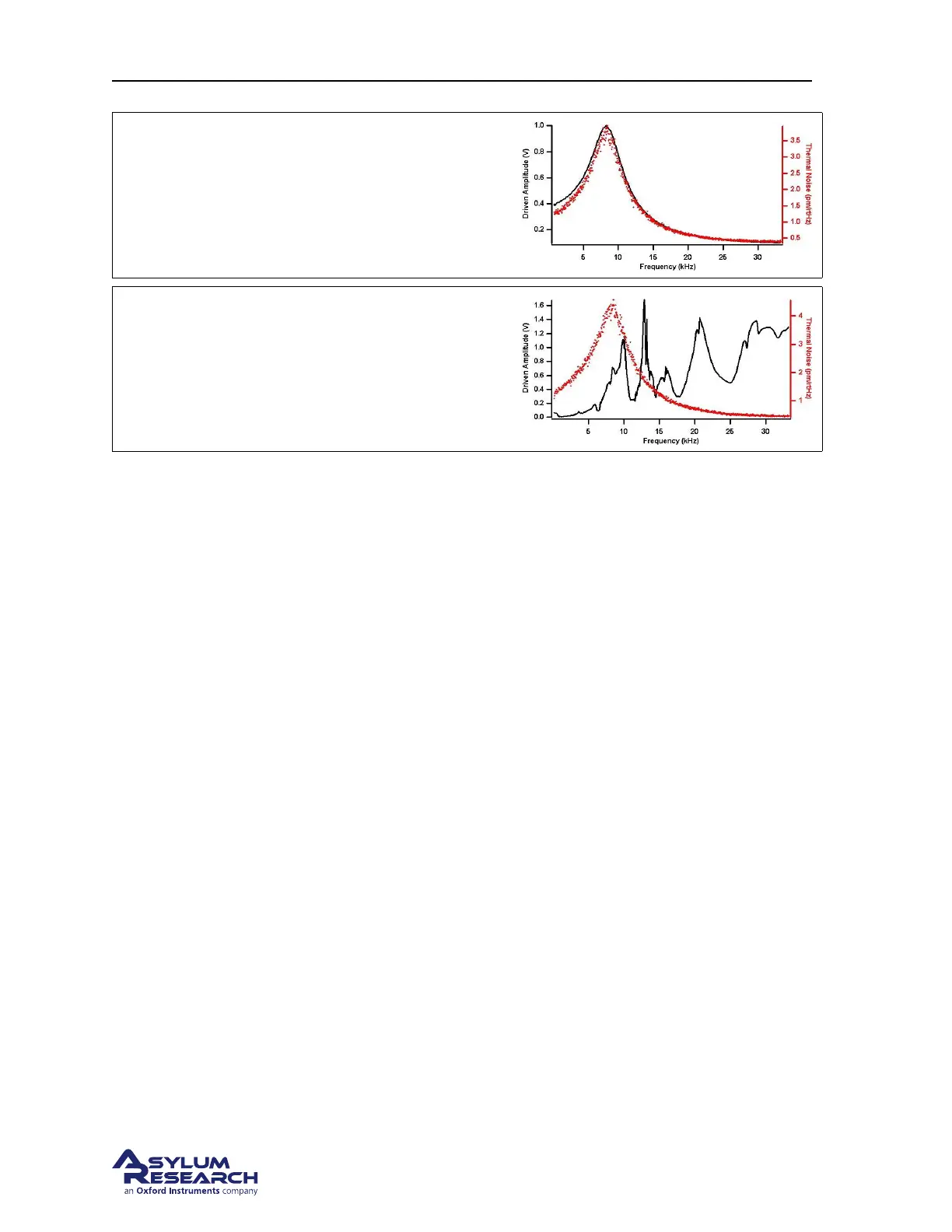

Figure Acoustic AC tune

Here is the same iDrive cantilever acoustically

tuned using the piezo actuator.

7.1.4. Imaging Specifics

Once the cantilever is tunes and you initiate the engage routine, you may notice the free amplitude

slowly decreases as the tip gets closer. This is due to the interacting of the steel sample puck interfering

with the magnetic field lines emitted by magnet in the iDrive holder. As you see this begin to happen

you may wish to increase the drive amplitude in the main controls tab. Generally a few “UP” clicks

while the tip is approaching is all that’s needed.

As a point of reference, a free amplitude of around 500mv may require 2-5v of drive. This is not a

problem but simply a point to note as you learn to operate the system with these types of probes.

Another thing to note is that the volume of liquid has lilt affect over the amplitude response. Since the

cantilever is driven magnetically and not by pressure waves transmitted through the fluid.

After an imaging session is completed, clean the cantilever holder before storage. If it is particularly

dirty, disassemble it before cleaning. Please see

7.2 for the details. When clean and dry, store the

cantilever holder and the other parts and tools in its designated kit box.

7.2. Cleaning and Repair

In daily use, the iDrive cantilever holder can be cleaned by rinsing the exposed surfaces of the glass

window and cantilever clips with clean de-ionized water. Following the rinse, the holder can be dried

using low-pressure compressed air or by blotting with a soft tissue.

For stringent cleaning, the iDrive cantilever holder must be disassembled. Only the parts exposed to the

sample liquid should be cleaned. The cantilever holder body and associated electronics should be kept

dry.

The cantilever holder clip, window assembly, Mounting hardware and evaporation control parts can

be cleaned by soaking in ethanol. Sonication of the parts can also be performed. Rinse the parts in

clean de-ionized water. Dry the parts with either low-pressure compressed air or a soft tissue before

reassembling the holder.

BETA

Page 80

Loading...

Loading...