Ch. 6. Fluid Imaging in a Droplet Sec. 6.6. Cleaning and Repair

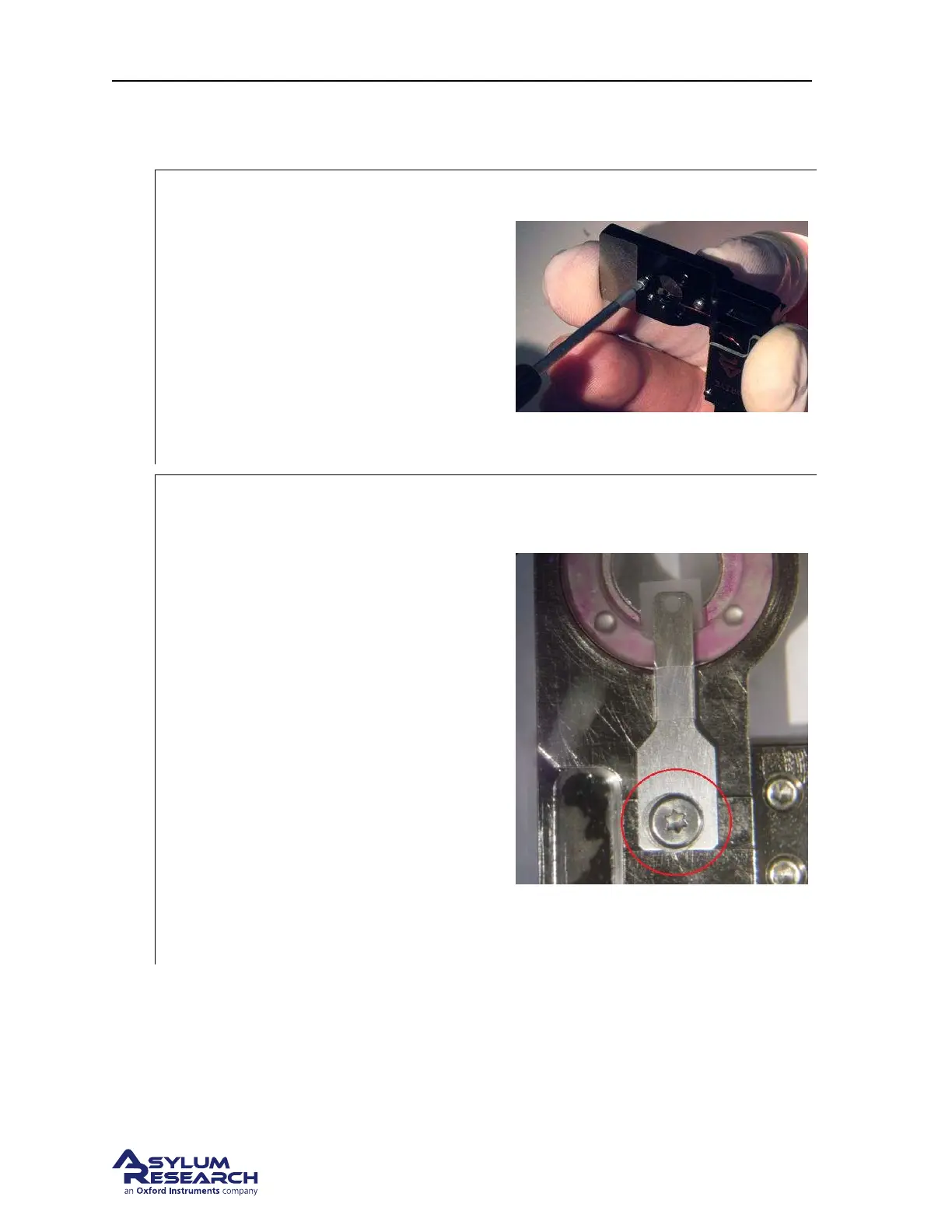

Note: There is a small recessed area in the metal ring where the piezo actuator fits. Be careful not to hit

the piezo or twist the window into position.

1.

Secure the window assembly

Tools 0.050” hex driver or Allen wrench.

• Using a finger to hold the window in

place, thread the three 0-80x7/64”

socket head screws the window to the

holder using. Once all three screws are

started, gently tighten them with

uniform pressure.

Note Do not over tighten the screws. A small

amount of torque is all that’s required.

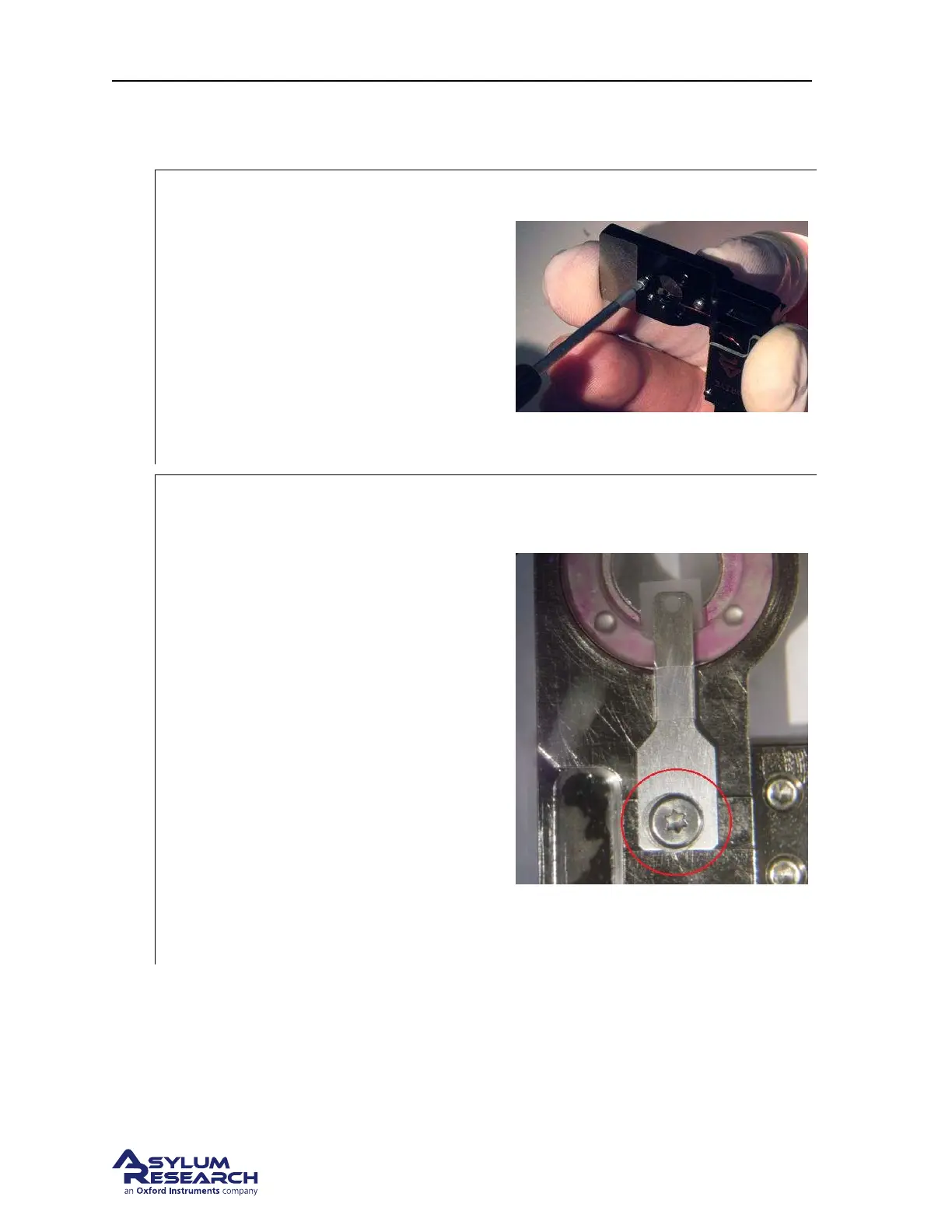

2.

Install the cantilever clip

Tools 0.050” hex driver or Allen wrench.

• Lay the cantilever holder body circuit

board side down.

• Place the clip on the holder body with

the taper on the clip facing away from

the window.

Note The end of the clip is tapered to provide

clearance between the underside of the clip

and the sample surface. Be sure the flat side is

against the glass and the taper is away from

the glass.

• Secure the clip to the holder with the

Torx screw and washer. The clip may

want to rotate as you tighten the screw.

Use a pair of tweezers to hold the clip in

the center of the ramp while you tighten

the screw.

6.6.4. Adjusting Piezo Preload

When first disassembling the droplet holder for cleaning, the preload screw was loosened. Doing this

allows you to readjust the compression on the piezo element properly after it is reassembled. This is

recommended since the amount of compression is very small and the piezo position may change when

you remove and reinstall the glass window.

BETA

Page 73

Loading...

Loading...