- INSTALLER 7 & 11kW HRC

70

HIGH TEMPERATURE HEAT PUMP

MANUAL -

15

3.2.5 - Desludging

We would advise you to t a settling tank (not supplied) on

under oor heating installations.

• The installation MUST be rinsed and

desludged before making the hydraulic

connection with the heat pump.

3.2.7 - Heating circuit

3.2.7.2 - Back ow prevention device

3.2.6 - Heat Pump water inlet lter (supplied)

A 1’’ valve with a built-in 500μm lter must be tted to the water

inlet piping on the Heat Pump:

• Respect the ow direction of the lter (arrow on the

valve)

• Install the 1’’ valve with lter on the inside of the

building and ensure it is thermally insulated

Clean the lter several times as soon as

the Heat Pump circulator pump has been

activated (take care to switch the circulator pump o

before cleaning).

• Clean the lter at least once a year.

For under oor heating installations, the

piping for the heating circuit must not be

under 1’’ in diametre.

3.2.7.1 - Heating circuit ow rate

• For heating circuits with radiators, fan coil units or under oor

heating:

The ow rate must be su cient to ensure that the di erence in

temperature between the leaving and return points is not over

15K in radiator or fan coil unit circuits or 7K in under oor heating

circuits.

For installations which have thermostatic valves, this test must

be carried out with all valves open.

The heating capacity from the heat radiating sources determines

the heating water ow rate and allows you to check that the

sections, lengths and layout of the hydraulic distribution

network are compatible with the Pilot circulator pump.

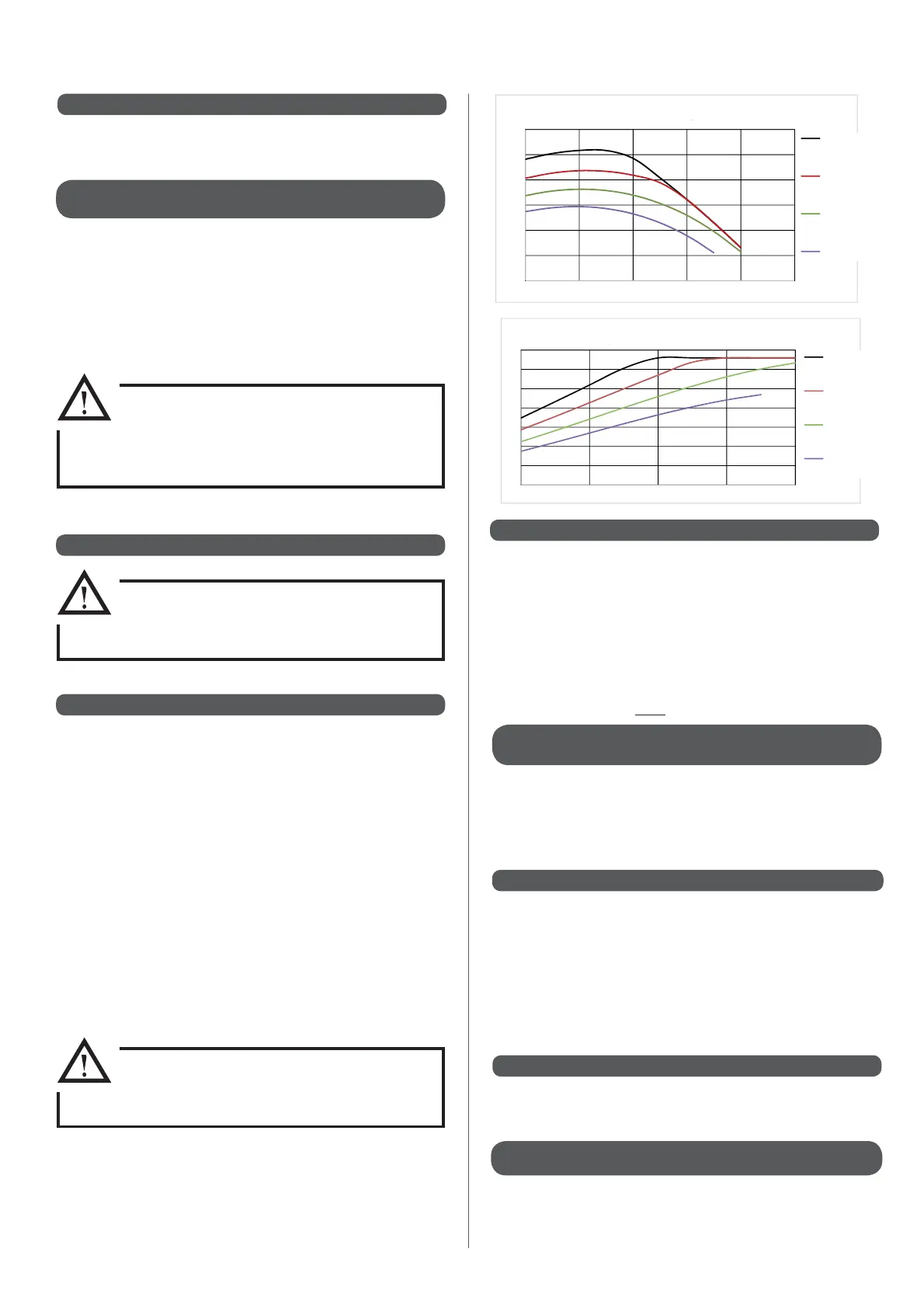

Adjust the speed (I, II, III, IV) of the UPM3 15-70 circulator pump

which is tted to the Pilot to the characteristics of the hydraulic

circuit using the curve chart at top of next column: ow rate Q

(m

3

/h) / pressure head H(mCE).

French law (articles 16.7 and 16.8 of the "Règlement Sanitaire

Départemental") stipulates that a type CB back ow prevention

device must be tted. This device must be at di erent, non-

regulated pressure zones, in accordance with the NF P 43-011

standard. This is also an obligatory requirement in other countries

so it is important to check the current laws and standards in

the country of installation and ensure that your installation is

in compliance with them. The back ow prevention device is

designed to prevent incoming heating water from going into the

drinking water circuit. It must be connected to mains drainage.

3.2.7.4 - Insulating the piping

3.2.7.5 - Expansion vessel

3.2.7.6 - Frost protection and water

treatment

3.2.7.3 - Degassing the heating circuit

All necessary measures must be taken to ensure that the

installation can be continuously degassed. Automatic air valves

should be placed at each high point of the installation and

manual air valves should be tted on each radiator.

Insulants must comply with DTU 67.1 or the current regulations in

the c

ountry of installation.

All visible piping and accessories (circulator pump, expansion

v

essel, valve, etc...) must be insulated

. Remember to insulate the

distribution manif

olds and the return and supply ow pipes to the

under oor heating circuit; remember to insulate

the piping which

c

onnects the Heat Pump to the Pilot.

An expansion vessel needs to be tted onto the heating circuit.

See Appendix 4 for help on sizing.

See appendices A3 et A5.

0,0

1,0

2,0

3,0

4,0

5,0

6,0

0,0 0,5 1,0 1,5 2,0 2,5

H(mCE)

Q(m3/h)

CirculateurUPM31550FLEXAS

hauteurmanométrique

vitesse4

réglage

usine:

vitesse3

vitesse2

vitesse1

UPM3 Flex AS 15-50 GGMBP3 AU CIRCULATOR PUMP

Pressure head

Speed 4

Speed 3

Speed 2

Speed 1

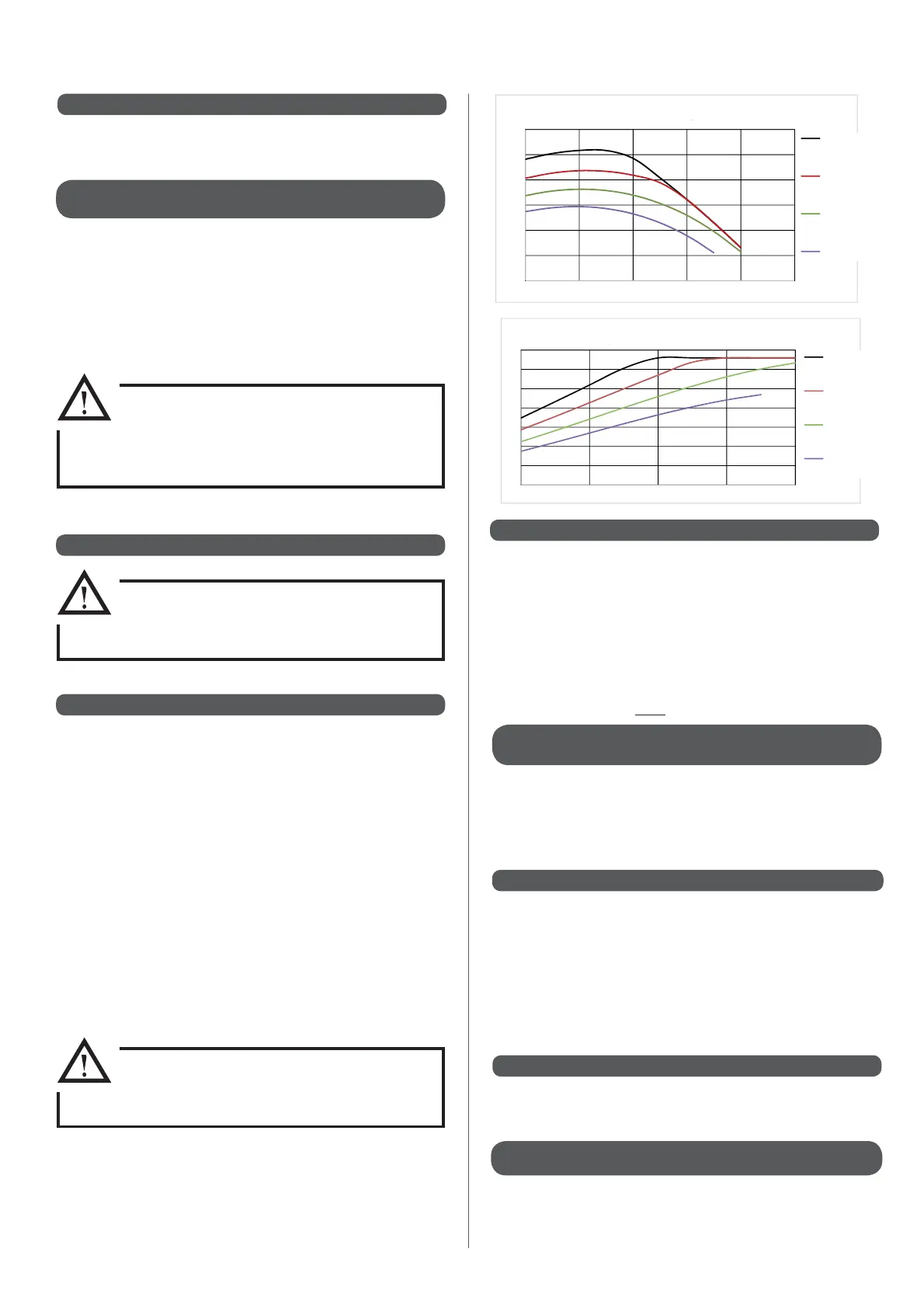

0

5

10

15

20

25

30

35

0,0 0,5 1,0 1,5 2,0

P(W)

Q(m3/h)

CirculateurUPM31550FLEXAS

puissanceabsorbée

vitesse4

réglage

usine:

vitesse3

vitesse2

vitesse1

UPM3 Flex AS 15-50 GGMBP3 AU CIRCULATOR PUMP

Power consumption

Speed 4

Speed 3

Speed 2

Speed 1

Loading...

Loading...